Hey @probrwr (or anyone else), with a revo hotend and EBB CAN Bus, my build is going to end up similar to yours.

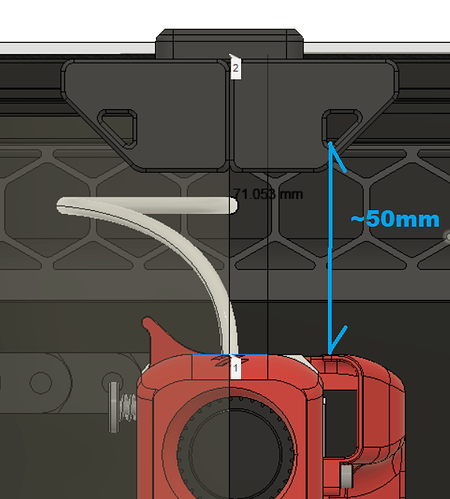

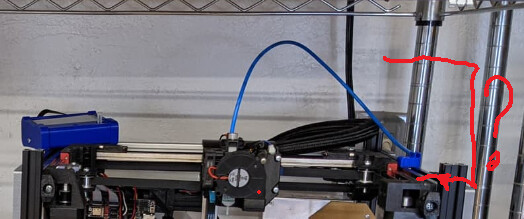

What height/gap above the top Y extrusion is needed to accommodate the hotend/extruder/can-bus and ptfe tube feeding filament from spool-to-hotend-carriage? Planning to enclose, currently have 200mm of extrusion going above the stock Y extrusions, which just looks silly at the moment.

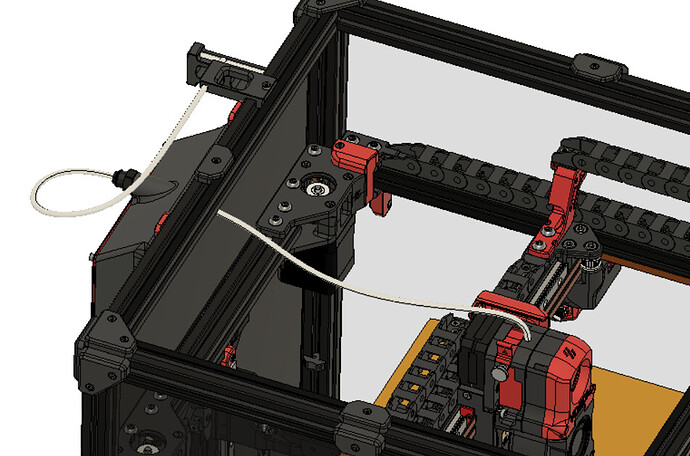

Below is pic of Ryan’s open build

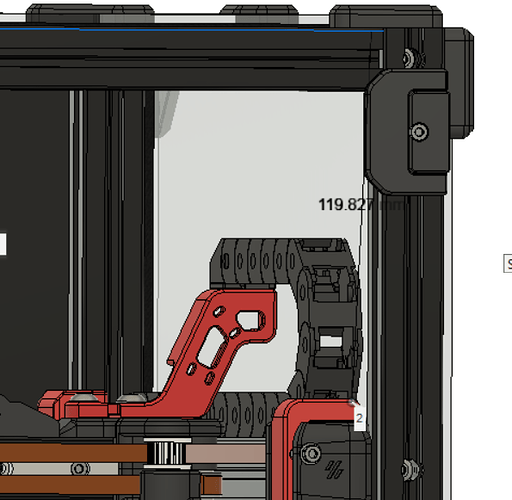

Voron Trident seems to have about 120mm from gantry, but their hotend is different to our BIQU REVO setups. They only plan for PTFE to take 40-50mm height to turn as they route and coil out the back.