The default in the slicer or the max_accel_to_decel in printer cfg?

The very very little I know about Klipper … seems great to me… Like the fact that if you need to modify the configurations on the MCU you can do it via the PC. I also like the Mainsail OS. However, there are things in Octoprint I wish I could do in Mainsail…

I have a learning curve ahead… but have some really good looking red printed parts to work with…

Been using klipper for about 10 months, First printer with klipper was the GridBot 2, then about 3 months ago I replace the board on the CR10S-Pro to be able to use klipper, as soon we are done printing parts for the LR3 (which I think I’m printing the last 2 parts right now) I will convert the Repeat to klipper.

The value you set at printer.cfg is the Default settings, and any settings you change in slicer will override your default setting…

So do it in slicer. Once you are happy, change printer.cfg to match your slicer.

Matt, you will be OK just like Chris, you just need to be patient. Several times I had to step away from the printer end the computer, otherwise I would smash both with a hammer… I did waste a good amount of filament tuning the 2 printers, and I’m sure it will happen with the Repeat too.

I keep getting this error during a purge line. I am now onto petg and before didnt have a purge line. Have no clue what is wrong

Move exceeds maximum extrusion (0.752mm^2 vs 0.640mm^2)

I never got that error msg, and I think it is because you are trying to extrude a lot of filaments with very little movement creating the purge line.

What is your purge line Gcode looks like?

I have a section on Printer.cfg for my start gcode and prime line.

[gcode_macro START_PRINT]

gcode:

#Get Bed and Extruder temperature from Slicer GCode

{% set BED_TEMP = params.BED_TEMP|default(60)|float %}

{% set EXTRUDER_TEMP = params.EXTRUDER_TEMP|default(210)|float %}

#Preheat nozzle and bed

M104 S{EXTRUDER_TEMP} T0

M140 S{BED_TEMP}

# Use absolute coordinates

G90

#Home

G28

Z_TILT_ADJUST #[<probe_parameter>=<value>]

#Use defaut bed mesh

BED_MESH_PROFILE LOAD=default

#Bed level

#G29

#Move up to clean bed

#G1 Y{Y_MAX - 20} Z{Z_MAX/4.0} F6000

#Heat nozzle and bed

M190 S{BED_TEMP}

M109 S{EXTRUDER_TEMP} T0

#Precondition extruder

G92 E0

#G1 X{X_START} Y{Y_START} Z{PRIMER_HEIGHT} F6000.0

#G1 X{X_MAX - 2 * X_START} Y{Y_START} Z{PRIMER_HEIGHT} F2000.0

#G1 X{X_MAX - 2 * X_START} Y{Y_START + PRIMER_WIDTH} Z{PRIMER_HEIGHT}

#G1 X{X_START} Y{Y_START + PRIMER_WIDTH} Z{PRIMER_HEIGHT} F2000.0

G1 Z2.0 F600

G1 Z0.2 F600

G1 Z2.0 F600

#Prime line

PRIME_LINE

M117 Printing...

######################################

# Prime line

######################################

[gcode_macro PRIME_LINE]

gcode:

M117 Prime Line

G92 E0 ;Reset Extruder

# move z axis

G1 Z2.0 F3000 ;Move Z Axis up

# move to prime position

G1 X5 Y30 Z0.28 F5000.0 ;Move to start position

G1 X5 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line

G1 X7 Y200.0 Z0.28 F5000.0 ;Move to side a little

G1 X7 Y50 Z0.28 F1500.0 E30 ;Draw the second line

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

I ended up removing it but I now have bigger issues… I start a print and at about 25% it stops extruding and the Clockwork2 Extruder sounds like its broken. I have tired it three times so I am giving up for today and moving over to my CR-10. Extruder set to 240c. PETG should flow very easily at that temp I’d think.

Chris,

I have found that when I increase the hot end temp I often get problems with clogging. The root cause (I think) is that the heat break conducts too much heat upwards and the filament starts getting soft before it gets to the nozzle. After a few retractions the incoming plastic is too soft and the flow stops.

I think if I can get a better fan on the heatsink above the heat break, I can solve the problem. At least that’s what I planning first.

Mike

Yeah. I think in my case on my printer I’ve been working it was heat creep. At the time I didn’t realize this so I switched to my CR-10 and running at 230c it has been printing just fine. However, two different set ups… CR-10 is bowden with MicroSwiss hotend and the i3 is direct drive with a phateus dragon standard flow.

Another thing that helps if to make sure your retraction settings are suitable for an all metal hotend (if you are using one of course). This page suggests

- Bowden Extruders: Recommended Value: 3.5mm

- Direct Drive Extruders: Recommended Value: 0.8mm

The direct drive one, at least, is likely much smaller than the default settings for your slicer.

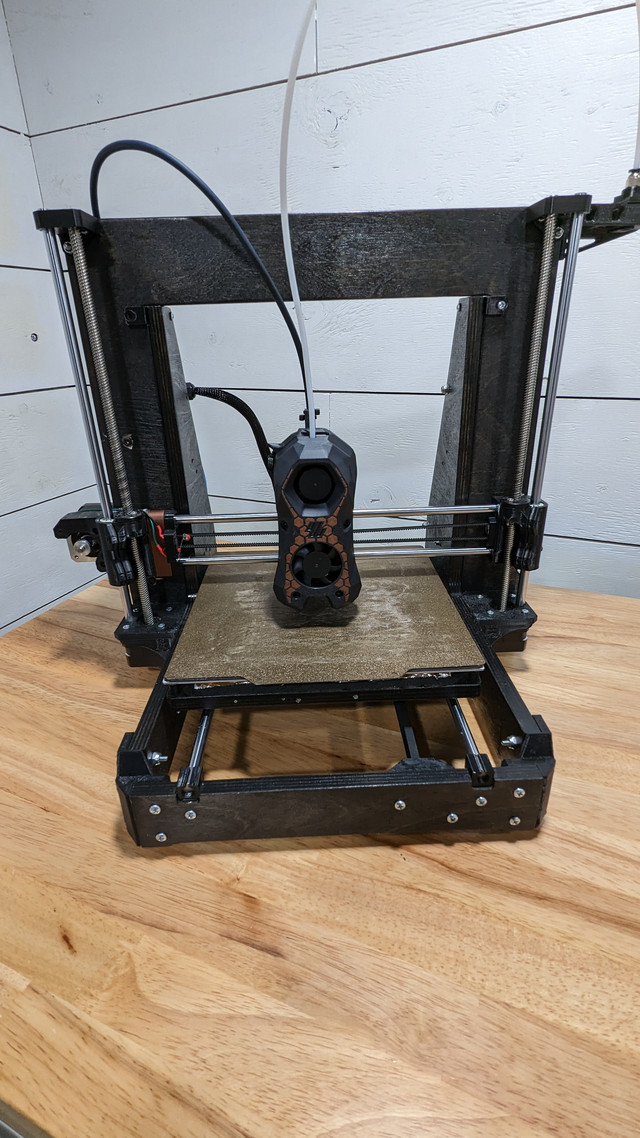

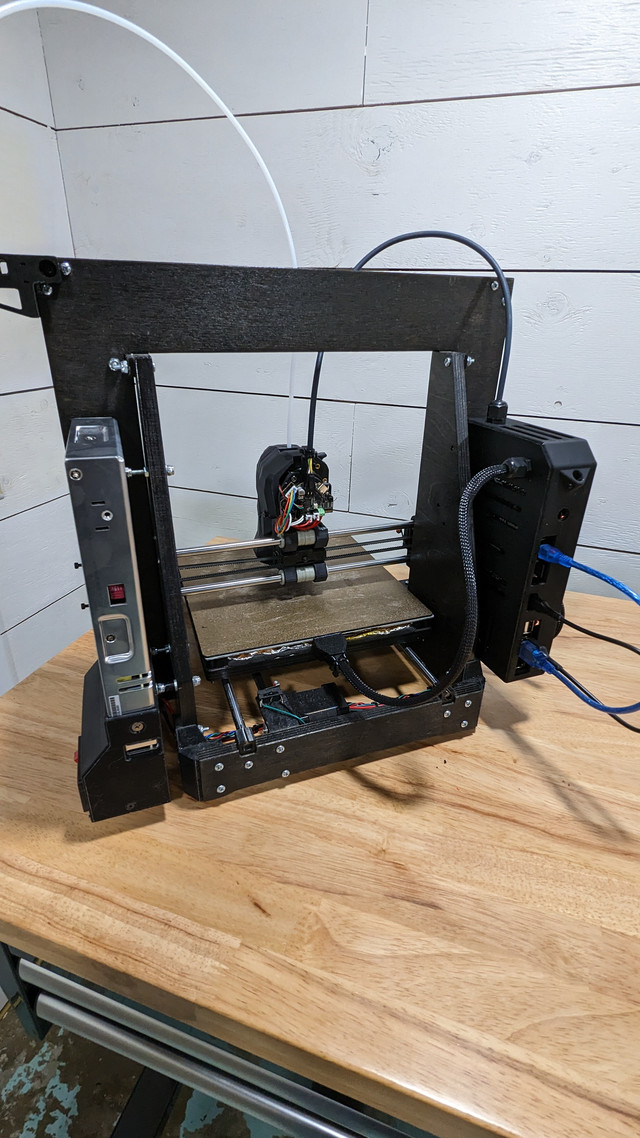

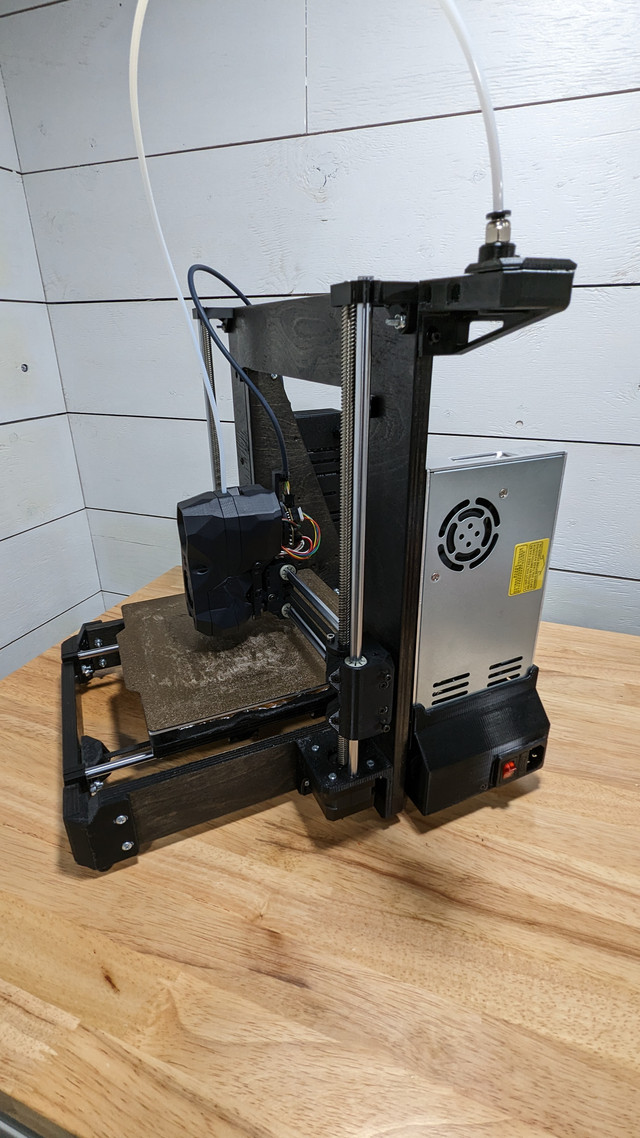

This is a way old post… that’s how long I had shelved the MP3DP v2…

I had started to scrap it… sold the Stealthburner and there it sat since last March.

I didn’t have the heart to throw it away so I rebuilt it.

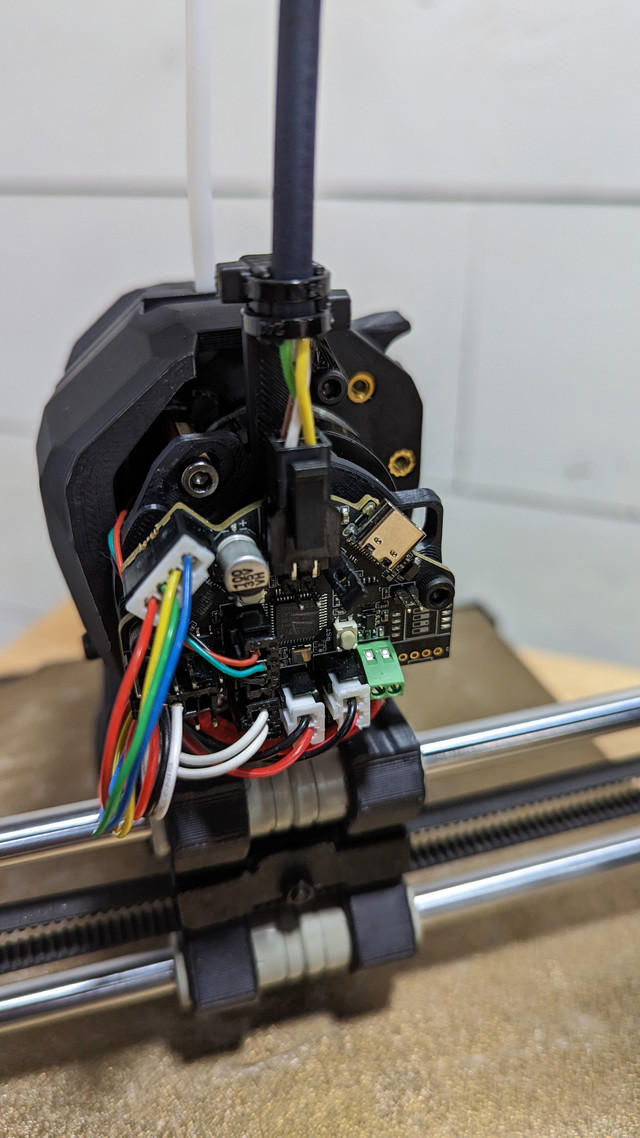

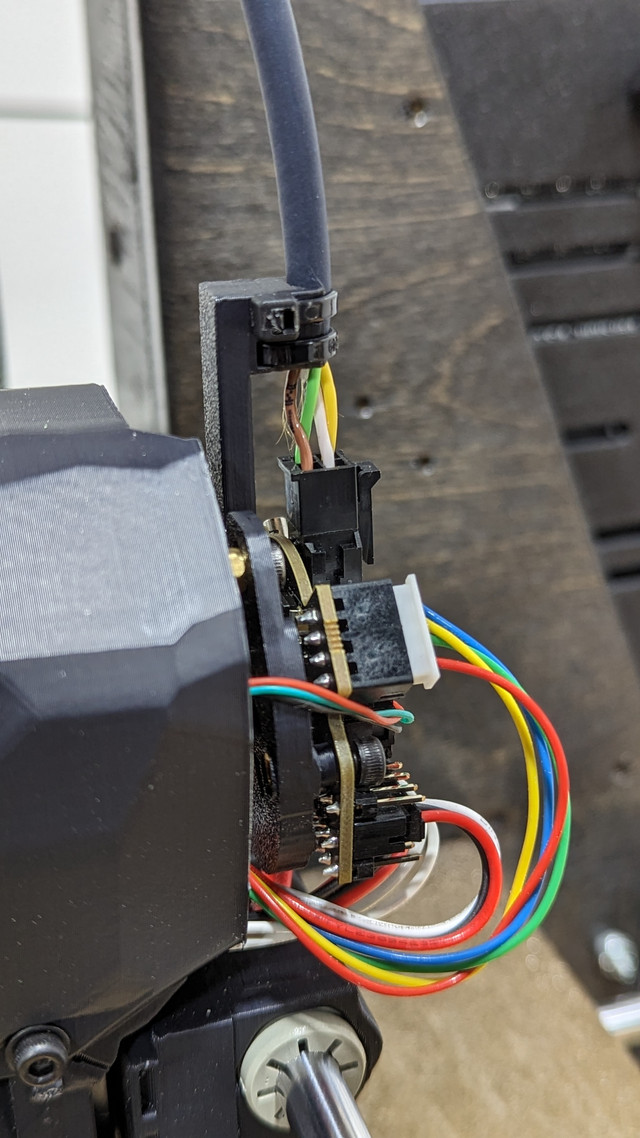

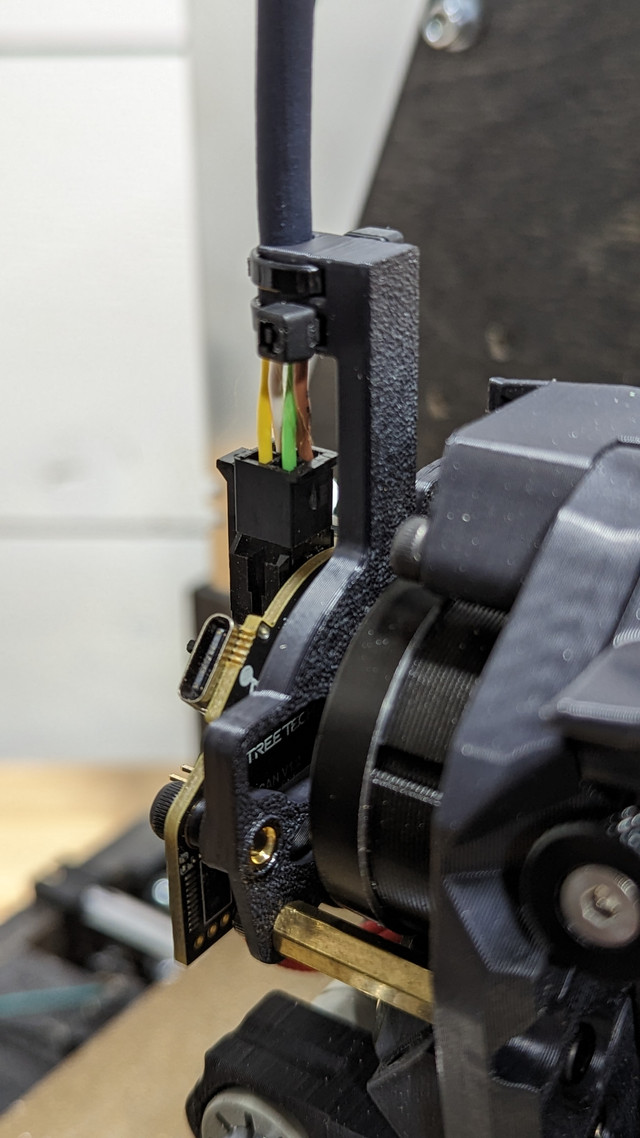

Added back the Stealthburner with a Bambu Labs hotend

Modded the X carriage to utilize Voron Tap

Added BTT EBB36 and U2C for Canbus Toolhead

Played around in Fusion a bit to mod a case to hold the SKR Mini E3V3, Buck Converter, U2C and the Raspberry Pi since I am running Klipper.

You know i have been on the fence of building one for quite a while. Do not need a x\y or cost!!

Wow, they both have parts that are better or worse. The bamboo was considerably faster though right, well maybe not with color changes?

Bambu top layer is amazing!!!

So you must not have ran identical gcode on both. Was the same slicer used for both?? I want to see a true comparison. Which bambu is it? It seems like everywhere i turn i read bambu

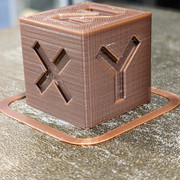

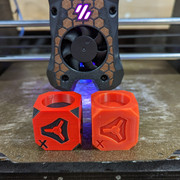

Two different slicers – Prusa slicer used on the red cube printed on the MP3DP v2 – took about an hour.

Same print settings in both same layer height, top/bottom, walls, etc.

Bambu was sliced with Bambu Studio which is derived from Prusa slicer as I understand.

It was printed on the X1C - that cube took 5.5 hours!!! This was my first multi-color print with the X1C and AMS.

If I print it with no color changes its done in like 20-30 minutes on the X1C depending if I do the auto level and flow calibration, etc.

The other thing to note is the red cube is pla and the colored cube printed on X1C is ASA.

@Ryan can I post the cube on printables? If not I understand.

Absolutely! Thanks for checking.

Only reason i asked, last weekend i tried a print from prusaslicer and it seemed to be a visibly better print especially the top layer. Cura seems to lack in that department it feels.