That is really epic and I am jealous.

Hey, with mad skills like you have shown up above, please keep posting, there is no way I could currently make what you made! That R2 D2 style controller, that is awesome, love the color combo! Then that cerf I think you called it, dang it. Get back into the scene! The world needs people like you! We need peeps like you!

I thought for a second that you might be the famous Aron Gough, of Gough custom knives. Your shop looks just as great as his. One day I’ll order a knife from him, they are fabulous. I bet you make amazing stuff to ![]()

Thank you Riley, that is the kindest encouragement I’ve ever gotten.

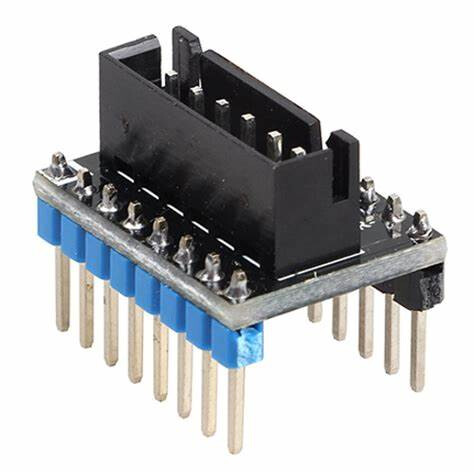

These work great. I am using something like it in my CNC mill to run the 23’s with 542 drivers.

Edit,

Apparently you already found those! Is that 19KW of solar? Grid tied or off grid?

It would be fantastic if you could post the files! I would be very enthusiastic to continue where you left off if you are not planning to continue development. I would recommend one of the 3D printing model repositories such as Thingiverse or Printables(dot)com, or email me directly if you would prefer.

Fantastic shop by the way! I am just starting my own automobile project with a homebuilt electric car, and I am planning to build a plasma tube notcher for that purpose. Your design is particularly well suited to longer tubes, whereas most other designs that rigidly grip the tube don’t seem as convenient.

Hopefully this does it- the link to download that model might be:

I know that model is an unholy mess. Good luck to you!

Hey Mike,

Yes, those little socket adapters are the bee’s knees. Maybe not closed-loop but still a way to control burly steppers from a 3D printer board. I need to learn more about closed loop steppers and servos.

The highest output we have seen from our solar array is 20 kW. Somehow I thought it would be up to 24 kW, but that was just my wishful thinking based on the capacities of the two phase matching inverters. It has a battery backup too, which isn’t super high capacity, but it should keep the fridge and freezer, well pump, septic pump, and basement sump pumps running forever. I guess as long as there is some light the next day, it would keep recharging the battery during the day to make it through the night. The whole thing is grid-tied, so we’re doing this Solar Renewable Energy Credit thing, and PA is a net metering state so we can bank kW-hours in the spring and summer and draw on that in the winter. My main disappointment in this is that when the grid is down, the solar for some reason can’t still power our house. The emergency circuits are powered through a transfer switch by the battery, but somehow we need the grid to establish an incoming AC sine wave or whatever.

Hope you are well ![]()

Cheers, Brian

Hi kkuehn,

Yes! That was something I was striving for, was the ability to feed and rotate up to 10’ long tubes, whereas the other notcher implementations I had seen used like a 4th axis chuck and travelling torch, which I thought would be difficult to make work with long tubes. This is all just academic until I try it, since I am worried that a 10’ long tube will be heavy enough that those tiny plastic gears might give up anyway.

Tube support with little friction or directionality was going to be key. I was either going to try and make some sort of air bearing deal or use some of these nondirectional ball bearing things.

Good luck with your space frame homebuilt car! That’s exactly the kind of thing I want to do. I’m excited to see that if you are posting updates here.

Hope you are well ![]()

Cheers,

Brian

Yeah,

They want to make sure you don’t back feed power during an outage so that the linepeople are safe. You obviously have the transfer switch but you can add as many of those circuits as you want to it to power more up to the load you can handle.

Thanks for the files! I’m getting the electric motor mounted in the rear subframe at the moment and debating whether or not to use soft mounts for it or directly weld in mounting brackets. My thought it is probably isn’t needed to soft mount because the electric motor will be low vibration.