I have a MPCNC Primo that I have disassembled due to space issues, but I am looking at reassembling it with a cnc rotary spindle. The problem I am questioning is that the spindle is driven by a nema 23 not nema 17. I’m looking to make a rotary mounted laser with a j-tech laser. I’m familiar with the j-tech laser and mpcnc but I have never tried to mix the motor types. I use Vcarve for another machine or is it better to still use lightburn for a set up like this? Not sure if anyone has tried to do a setup like this before.

I have no practical knowledge about this configuration, but, having played with stepper motor projects over the last year, I have some guesses. I’m assuming you will want to swap this configuration between rotary and rectangular work. If you have replaceable stepper drivers on your control board, I’m sure you can make it work, but, depending on your setup, it might be simple, or it might be involved. The big issue for me is whether the stepper driver you are using will handle enough current to effectively drive the Nema 23. It would be really helpful to know:

- Model number of the Nema 23 stepper motor

- Model number of the Neam 17 stepper motor

- What control board you are using

- If the stepper drivers are replaceable, what stepper drivers you are using

So, I could see the transition being easy, where all you had to do is adjust the current setting, and perhaps the steps per mm. I could see it being much harder where you would need to swap between an internal stepper driver and an external one, and flash the firmware each time you made the change.

Is this like one of those point of sale countertop scanners that use lasers and rotating mirrors?

…or is this just a laser mount with a 4th axis style rotary mounts (for the material, not the laser)?

AFAIK, other than the step rates, drivers, and voltage used, there should not be much diff between nema17 and 23… to the software they’re all just steppers anyways. I think the larger challenge here will be sorting out control of a rotary axis, and the CAM required to create the proper gcode from the models you make. I haven’t looked much into details of that kind of work yet since I don’t have a 4th axis yet, but it is something I’m interested in. AFAIK, most guys burning vases on cnc are using mostly 2d stuff, like inkscape… and operating in a pseudo 4th axis mode, where Y movement is simply translated to fit the local diameter of the material, and sent to the A axis. For actual 3d carving with 4ax, the only home built examples I’ve seen of that use grblgru… which is above my head ATM.

I’ll chime in and in the spirit of work avoidance, echo what others have said. A stepper is a stepper is a stepper, electrically. It will have different ratings as far as amperage, steps/rev, etc., etc., but it’s still basically the same coils and magnets. The key difference between NEMA 17 and NEMA 23 is the size, specifically the mounting holes and their spacing. Quite literally, that is the only specific difference between the two. You can get monster NEMA 17 motors that can out-perform a NEMA 23 pancake motor on every metric.

It’s usually bad form to mix and match, but that’s often a function of maintainability, as you then have to make sure you’ve configured that one driver for the different voltage/amperage, and adjusted the steps/mm for that one motor, if needed. In the OP, the use case isn’t a contra-indication, as it’s a single motor for an axis (either a pseudo-2D axis, or an actual rotational axis). But never mix and match paired motors. That way lies madness!

My k40 is set up this way. Works fine, although i had to increase the current to the 23. I can still overcome thw motor by hand with not-too-much effort.

If you were carving on it with a router, I’d say replace the driver with a much bigger one, but for a rotary laser, holding torque isnt a big deal

I’m trying to make a 4th axis CNC machine. Sorry for not specifying that. I made a 4th axis wood CNC Lathe from the Lead Build design. I got an extra rotary spindle from this build. I have seen the homemade rotary tools that use Stepper 17s but I’m just trying to use what I have laying around instead of having to make or buy. I dismantled a MPCNC Primo to make space for my new machine, so I have all the 3D parts and motors and rambo board laying around. For the rotary portion I do have a stepper control that will give me the extra power that the Nema 23 will require. I’m just trying to figure out how to wire the stepper controller into the rambo board and if I will have to adjust speeds or steps to make it so it spins curatively to the X and Y axis that are Nema 17s. I’m not doing it to get more power from the rotary just using what I got.

With a Rambo board, your choices are limited. The stepper drivers are hardwired. The Rambo uses A4982 stepper drivers. They have a 2.0A max current, though when setting them up, you want some safety margin…maybe run at 1.6A to 1.8A. The question is whether that is enough current to effectively drive your Nema 23 motor.

The Nema 23 stepper motor in the ad you link in your post draws a max of 2.8A (Model 57HS56). You will need to test things out to see if the 1.6A to 1.8A you get from your Rambo board provides enough torque for your task.

As for adjusting the current, I believe it can be done using g-code or the display. The Rambo board uses “digipots.” If you prefer to change the current in the firmware (assuming Marlin), you can edit the following line in configuration_adv.h.

#define DIGIPOT_MOTOR_CURRENT { 135,135,135,135,135 } // Values 0-255 (RAMBO 135 = ~0.75A, 185 = ~1A)

The Nema 23 motor should have just two coils with a 4-wire cable, and connect to the Rambo just like you did with the Nema 17 stepper motors.

For the rotary portion I do have a stepper control that will give me the extra power that the Nema 23 will require.

I assume this is an external stepper driver…probably a TB6600. You cannot use this with the Rambo board. To use this board, you will need to use a control board what has replaceable stepper drivers. If you are trying to keep costs down, it could be something cheap like a Ramps 1.4 board. You can get a Ramps kit with the Mega board and five drivers for around $30. I have seen wiring diagrams for directly connecting a TB6600 to a Ramps board, but some forum posts suggest using an external breakout board like this. Here is the same board on Aliexpress.

Assuming Marlin, you will then have to set the stepper driver in configuration.h. Between your breakout board and your external driver, you will have four wires: ground, enable, direction, and step.

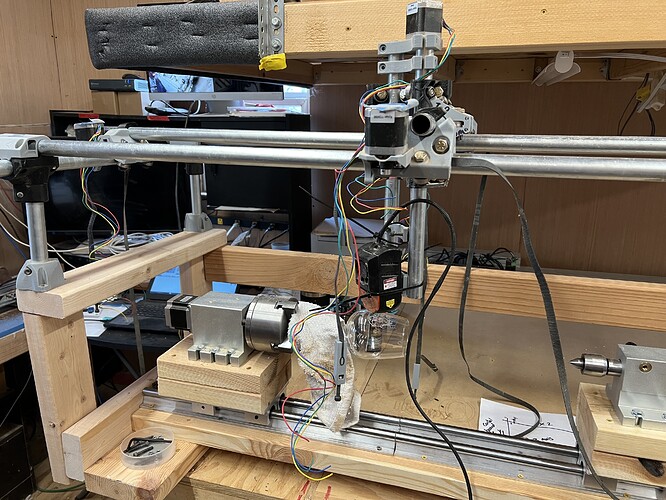

That is what I got so far. I did the wood frame to keep the conduit legs shorter. I need to shorten the legs cause the z axis doesn’t go as low as I need. I’m gonna start wiring this week and I will see how it goes.

It’s so great to see how versatile the Primo is. Surfboards, Wineglasses, Wood. Everything goes. ![]()