How is this project coming along? Any updates?

Nothing at this time.

I have not been in the garage since my last update as my long haul COVID issues had not gone away and I started having severe vestibular issues with eye tracking/balance. Most of those issues have resolved after both vaccine doses (Pfizer), and my physical therapist has released me from our weekly sessions.

I have a new power drop being installed from the house to the garage this week, bumping from a single 20 amp circuit to a 100 amp sub-panel… Once that is complete, I’ll be back on track to continue using the LowRider while I wait for the steel table frame to finish being made.

am following along here… looks like you’re Powering along nicely…can’t wait to see some updates on the hybrid system.

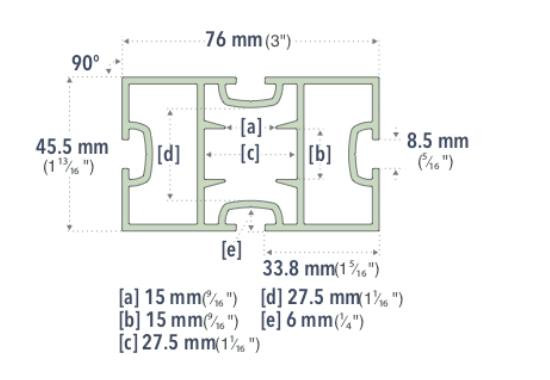

On the CNC front: Progress is finally being made on my upgrade project. The LowRider is being dismantled so I can replace the wooden CNC table with 2X3" aluminum extruded “studs” with T-Slots. These are used for the support structure behind the scenes at large trade shows, and they hold up most of the giant trade show displays… I got a hell of a deal on the entire trailer full. 107 bucks for a 5.5’x10’x18" deep trailer full. New, a single 72" chunk of this stuff retails for 132 dollars. I’d say I got a hell of a deal.

I posted about this on a DIY CNC group, and stumbled across a guy local to me who traded some linear rails and the like to me in exchange for a stack of extrusions, so my large machine project is coming along…

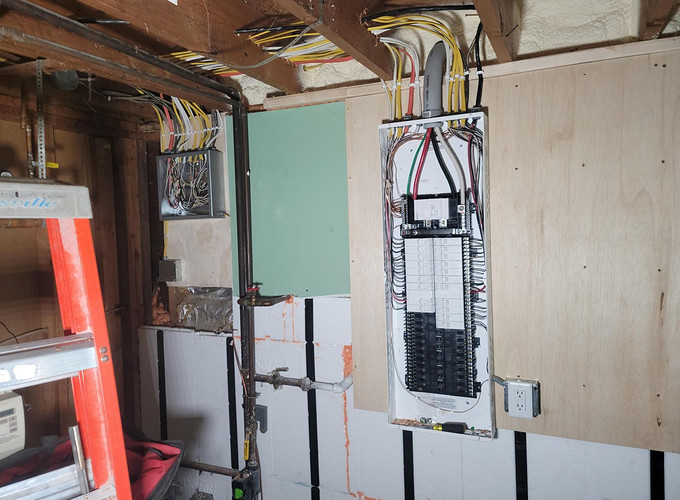

I also had the home electrical panel replaced to bring it up to code. Installed a smart panel, and now have a 100 amp dedicated circuit running to the back shop/garage where the CNC is. This entire project involved ripping out a lot of water damaged insulation, furring strips, etc, and spray foaming and insulating the basement walls to make room for the new panel.

Old panel location is the left side where the large junction box is.

On the post-COVID long haul stuff, a recent MRI of my brain shows several areas with noticeable damage. The smell/taste sensory area has atrophied, and is smaller in size than a previous MRI from 2017 showed after a head injury. I also have a reduction in the hippocampus, the area where short term memories are stored. These are generally transferred to the cortex during sleep when the brain takes the day’s “buffer” and moves it along to make room for the next day.

This damage explains why I struggle to retain details from conversations and the like. I used to be able to pick up on everything in a conversation and hold it, even through the day, weeks, or sometimes months and recall it perfectly. Now I need to fall back to skills with note taking, memorization practices and the like… Things I’ve never needed before. I’m a 42 year old man having to learn things they teach in grade school to help kids learn how to learn… Frustrating is too small a word. The vaccine helped me a ton, and about 80% of my long haul stuff is gone now. I’m learning to be more mobile again, and I’m excited to get back out into the garage.

Oh man. That is some tough news to hear. It is really hard to think that our brains are these machines that can have wear and tear. I am really sorry that you’re dealing with that. I hope it only gets better. Getting into that garage and making a mess will feel natural for you.

My electrical box is pretty old. I imagine they can’t just use the original wires to the next box, so they extend each one over to the new panel?

If you move your panel, they can junction properly inside of a box and extend the circuits to the new panel. In fact, electrical panels qualify as junction boxes if you add a solid cover and gut the interior. You just have to be mindful of volume of space inside the box as well as volume of wire. You have to have a certain percentage of free space.

If you keep your panel in the same place, you can legally junction the circuits inside the panel to extend them to where the breakers are located in the same panel.

We had to move ours to meet code. There is a floor drain directly beneath the old panel, pipes in front of it, etc. The new location brings it out so it complies with code and gives me room to add/rewire. We’re also installing new hardwood in the main level. This will involve ripping the cabinets out so I can put it in underneath. Since I’m going to be that far in, now it’s time to rip all the old wiring for the kitchen outlets out and run new 20 amp circuits. I didn’t have room in the old panel. I do now.

Glad to see you back in action!

Hopefully our brains are able to quickly rewire themselves, like you did in the shop. That would mean it takes a lot of work to get there but it turns out better in the end.

I am super jealous of that extrusion, haul. That is going to be fun to use.

Oh, you have NO idea… Erector set for adults!

This one’s a big update.

First: LowRider is in pieces, and will not be reassembled. No room for it in the garage space, now that the wife has approved the garage becoming a dedicated wood shop due to some unforeseen issues with my power tools.

Some recent trips through an auction site have resulted in 1200 square feet of engineered hardwood flooring for less than 1.50 a square foot. So now we’re re-doing all of the floors in the house, replacing poor quality laminate and old carpet with hardwood, encapsulating good condition vinyl asbestos tiles with tar paper underlayment (spec’d by the manufacturer) and nailing the planks down, etc… Before you say anything, several flooring pros said that this qualifies as encapsulation and is just fine, because the wood becomes “structural”… The poplar on the stairs is a placeholder.

Anyway, the flooring project resulted in my wife and I ripping some planks to width on my portable jobsite saw, when the saw stand collapsed while the saw was running. She freaked out, and I now have a new hybrid saw (contractor/cabinet), as well as a new miter saw, and more. She went whole hog to make sure I don’t kill myself in the garage, and has told me to finish the wiring, insulate the walls/ceiling, and get everything covered with plywood. I couldn’t possibly love her any more than I do right now.

So, LowRider is down. Big machine is coming along, and I’m wiring the control box for it right now with a 220v 3-phase VFD and water cooled 2.2kw spindle, 80v power for the NEMA34s, etc. I have the motion system sorted with 2505 ball screws for X/Y, and one hell of a set of linear rails for the Y-axis… This one will be built within the next two or three months. I have a need for a CNC right now though, as said auction site also resulted in 1400 board feet of 2" thick walnut and birch slabs. Remember the stair nose place-holder above? Yep. Solid birch stair nose on the way. The walnut on the other hand is going to turn into solid walnut butcher block counters for our kitchen, and the remaining 1200 board feet will be turned into end-grain butcher blocks…

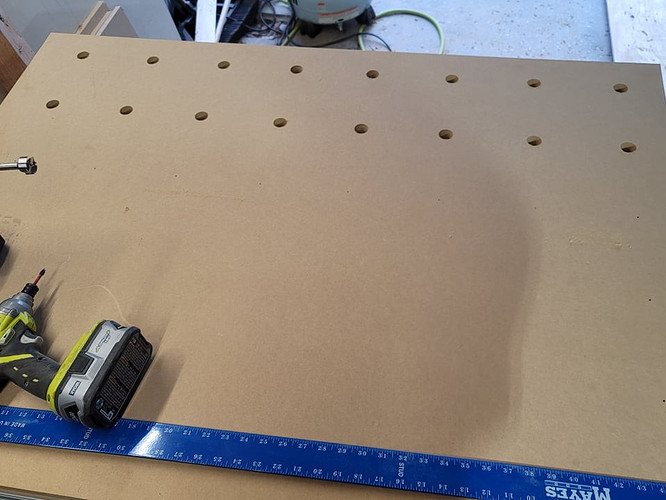

So, back to the CNC stuff… What does this post have to do with the LowRider? Nothing. I just ordered the Primo kit from Ryan, and will be assembling that as soon as it comes in. The aluminum extrusion mentioned above? Fully enclosed CNC housing for turning those end grain butcher blocks into inlaid end grain butcher blocks, cutting boards, carvings, etc. The Primo will serve as my small job machine, churning out repetitive stuff that is quick to do. The big machine will handle all of the long jobs, since it can do it at higher speed and deeper passes.

And that erector set for adults? Yeah… You can do some super cool sh*t with it.

Miter saw station (this is now finished with a table on the left as well)

Dust collector ladder frame and filter box.

Outfeed and assembly table.

COVID update: October 1st marks 1 year since my positive test and the long haul nightmare starting.

I recently started going for morning walks.

I walk a mile every morning, unassisted, without leaning on anything or stopping, and I do it in 20 minutes or less. I am down 30 lbs in the last six weeks, and working on getting back into the gym and back to my power lifting within 6 months.

Those are some beautiful floors, cutting boards and shop furniture  . I can’t believe you’re still dealing with that crap after a year. I hope the pace of the recovery picks up so you can spend more time in that epic shop.

. I can’t believe you’re still dealing with that crap after a year. I hope the pace of the recovery picks up so you can spend more time in that epic shop.

Thanks Jeff. I’m now 100% physically recovered, and working on losing the weight and regaining strength, stamina, and mobility. I still have brain fog sometimes, and my short term memory is completely shot, but I consider myself healed.

I’m excited to get into the shop. A friend of mine is selling his home… He bought one of those large in-wall AC/Heat units that you find in every hotel room under the window and never installed it in his workshop. I’ll be getting that from him and installing it in-wall in the shop, so I’ll have heat this winter. I’m beyond pumped to get back to life and start making things again.

Nice. You have me dreaming if doing some upgrades inside and the garage as well…I bet you are having a good time getting the new shop prepped!

Yet one more project I still need to start… The build-out of the shop walls and storage.

I threw up temporary shelving when we moved in 2 years ago with the hopes of putting in built-in benches and cabinets. I also have a need/want for a loft over part of the work area.

Oh well… one day…

Nothing is more permanent than a temporary solution.

It can be a life changing illness I know from experience also. The after effects are devastating but like you getting back keep it up.