I am also an owner of 2 original maslows currently though these are # 3 and 4 of the ones I’ve owned. and I’m teetering between the lowrider and the maslow4: imagining that the 4 should be less of a tinkering experience and will just cut the big panels, which is what I need while for the lowrider, it is the build experience of assembling the kit or printing and assembling it and I lack the time for this one, though I really like the lowrider gang. the MPCNC is pretty great for what I’m doing.

Pretty sure all the changes will get combined before too long. Once we all get on the V3 train, I think the brain power will be less scattered. I actually asked him a few questions about it so hopefully we will all be running the same interface eventually.

I hope so, i’ve got raspberry pis in my machines just for the outline macro that i have in cncjs ans i would love that finally integrated in the web ui.

I know it’s not specifically in the roadmap but i was thinking of giving a go at implementing it myself but with all the changes it looked like a mess

Maslow recently moved into an office very close to GlowForge. There’s literally just a weed and coffee shop between them.

“if you are in the Seattle area and want to come by and say hi this weekend, our shop is open Saturday from 11AM on. We’ll be at 1952 1st Ave S #3, Seattle, Washington.”

Planning to do a field trip and stop by 12’sh if anyone’s around. Cheers!

Oh dude that is cool, have any stickers to bring him? ![]() we have been in contact a few times since Open Sauce.

we have been in contact a few times since Open Sauce.

Got to meet, hang out and chat with Bar and other Makers at the new Maslow Office. Got to see and learn more about Maslow 4. Looks even better than the version we first saw at the OpenSauce madhouse.

Maslow 4 looks like a great machine. Kicking myself for being too slow to join the Kickstarter. The Kickstarter folks seem to be well taken care of and are being prioritized. Was impressive to see Bar’s commitment and progress towards delivering a quality product, as soon as possible.

Saw lots of great quality printed and injection molded materials.

Liked the flexible self calibration for 4 arbitrary anchored points (anchor placement doesn’t matter, this is neat). The ability to mount 15 deg from upright was great. Liked that when starting out you could layout on a car bay floor, or 4x8 sheet even, for fast day 1 bootstrapping. Some interesting controller software, and broader community software too…

Dropped off some housewarming stickers…

That is rad, I wish I could have gone. (Did you touch Nirvana’s door?)

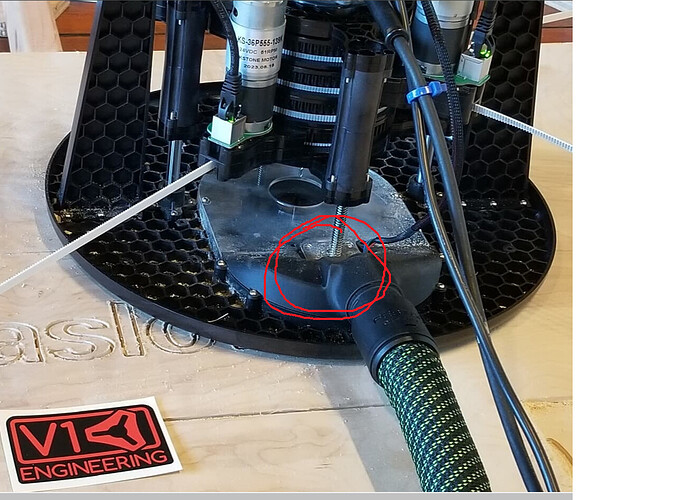

The base looks like a cut-up Prusament spool. ![]()

Lol, yeah, lots of hexagons throughout the design. The injection molded fiberglass reinforced polycarbonate looks great in person. Nice matte stealth black look.

The corner brackets also look awesome, and awesome strong. They’re Overture Matte Black PLA using prusa slicer’s default PLA settings. Bizarrely, that’s the exact same filament I was hating on recently… So, looks like my ability to print that filament is the problem.

Saw the historic doors, they were cool.

Forgot to mention in earlier post… Liked how the Z Steppers have integrated leadscrew shafts, despite the additional cost, maybe harder to source, that seems like one way to minimize part count and risk of assembly fluff ups with grub screws and such. Seems to help make assembly/design height more compact too. Slight negative effect on packaging/shipping maybe.

However, I have no mechanical background, or idea if/how this would positively, or negatively, effect performance though… Have no clue how performance compares with the spring couplers used on V1E LR3, maybe the coupler’s slight spring give helps to absorb some momentary shock rather than skip a step?

I think they would be a great idea. If I get the MPCNC and LR on the same length lead screw that is a possibility.

The coupler does typically add some play to wonky prints, but the LR3 doesn’t allow for any wonkiness and there are very few issues. So this could happen in the future. The other downside though is some are using the other leadscrews to adjust the steps per mm, this would take away customizability a bit.

The Prusa MK3 came with those. I got excited and my mp3dp v2 had them as well. Ryan’s two points are spot on. Very little room for error and harder to customize. But if you could keep the design so that couplers were an option, even with a small compromise, then maybe it would work for everyone.

It reminds me of the camera suspended over the NFL games…