Could somebody please point me in the right direction to the setting to turn of moving the machine out of the way when a job has finished. I’ve narrowed it down to it not being a gcode command, so it must be set up in the firmware.

I have a BTT SKR Pro V1.2 running V1CNC_SkrPro_DualLR_2209-2.1.1 firmware, connected to a BTT TFT35 display running BIGTREE_GD_TFT35_V3.0_E3.27.x firmware.

Moving out of the way is a good idea at the end of a print, however the movement is relative. So if the job doesn’t start at 0,0,0 the machine runs against the end stops when it tries to move out of the way

How have you eliminated that being a gcode command? It almost certainly has to be, I think, as this is not normal behaviour.

Estlcam, for example, has a setting to end the job on its clearance plane over the origin, and the last gcode commands will first move it to the clearance plane (IE: G0 Z5) and then move to the XY origin (G0 X0 Y0) and that’s where the job ends.

After that, though there will be the “end gcode” which could do something else to “move it out of the way”

For a LowRider, I might put in code like G28 Z to raise the gantry to the Z end stops. It shouldn’t run against the Z stops that way. I might home the whole machine, but I’m pretty sure that your “move out f the way” is gcode inserted at the end of your job, probably by whatever you are using as CAM.

Repetier Host also puts gcode in at the end of jobs, often doing things like turning motors off, but the TFT puts nothing in at the end of jobs that I am aware of. (And if it does, I would also want to stop it.)

I am using Repetier Host to send the code. A sample file that I am using to try to solve feed rate issues is:

;----------;

; Filename: Toolpath test 4

; Comment: Profile

; Description: 6.350 mm dia. slot drill

; ToolpathName: Sinoprotools SC010401D SC Spiral Plunge 1/4" Dia x 1/4" Shank x 1" Cutting Length 1" 2 Flute Down-Cut Router Bit

; Home Position:

; X:X0.000 Y:Y0.000 z:Z10.000

; Safe Z: 5.000

; Relief Limits :MinXYZ: 0.000,0.000,0.000

; MaxXYZ: 570.000,840.000,0.000

;----------;

;

;

; Millimeter Units

G21

; Set Position

G92 X0 Y0 Z0

; Absolute Positioning

G90

; Set Fan Speed

M106 S180000

; Set Max Feed Rates

M203 X2400 Y2400 Z400

Go to Home positions

G0 X0.000 Y0.000 X0.000

;----------;

;

;

G0 X285.000 F2400 Y420.000 Z-50.000

G1 X0.000 Y0.000 Z0.000

;----------;

;

;

;Spindel/fan off

M107

;Motors off

It carries out the script, and then shoots off to the far end (at a higher feed rate than that set by the M203 command.

That would have been good information to include in the first post. ![]() So it has nothing to do with the SKR, Marlin, or the TFT (Or it’s associated firmware.) The TFT doesn’t get involved at all between Repetier Host and Marlin.

So it has nothing to do with the SKR, Marlin, or the TFT (Or it’s associated firmware.) The TFT doesn’t get involved at all between Repetier Host and Marlin.

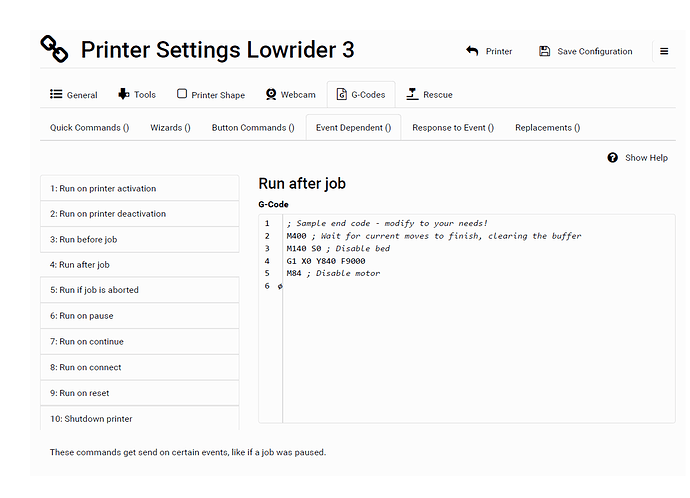

I do not and have not ever used Repetier Host, so I’m not 100% sure, but in the printer configuration settings, there should be start and end scripts (I think under “Printer Settings” then the “scripts” tab) that should have gcode that Repetier will send when it ends a job.

Thank you for the pointer. The puzzle is solved ![]()

For anyone else who is having any strange issues while using Repetier. The problem isn’t in Repetier Host, it’s in Repetier Server ( I set up Repetier to communicate through Server rather than talking directly from Host). Below is the offending item:

I believe Repetier Server is discouraged to install in the manual, not 100% sure, but believe I remember i’ve read this somewhere.

I currently don’t have a touchplate, but this is what i just currently wrote in Estlcam:

In the starting of a sequence i just have G92 X0, Y0, Z0;

At the end of your sequence you could add a G28 command to move the spindle up to home position eg. G28 Z;