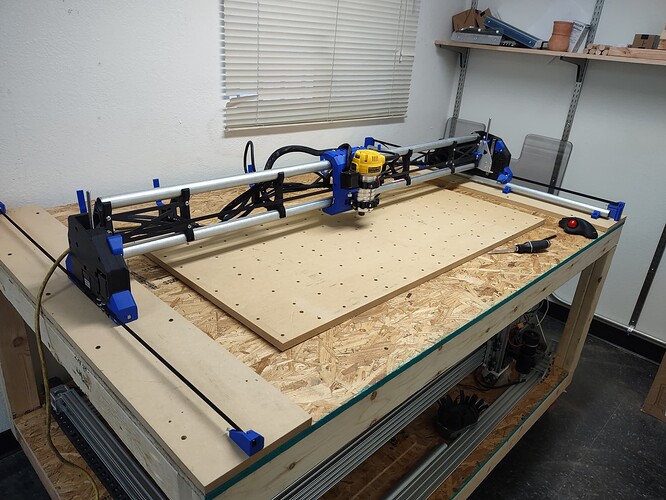

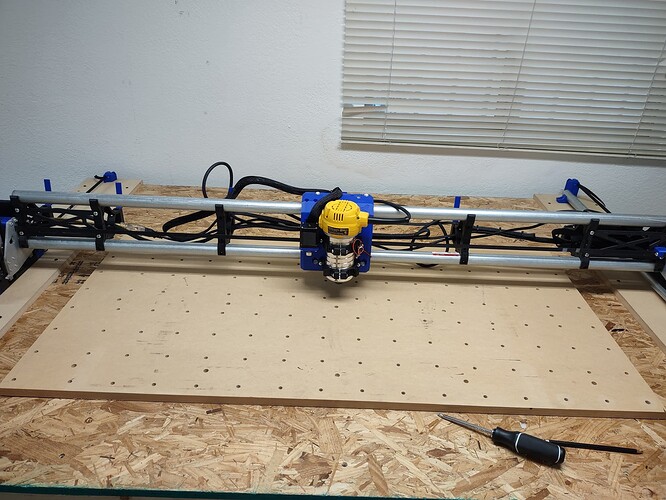

All parts printed on Bambu P1S using Inland PLA+ and Bambu PLA except tool holder which I did in PETG. Parts came in this past Friday. Everything went smooth except a bad connection on one of the z end stops. I still have to square everything up and double check to make sure the steps per mm are correct. Currently I have it on a small table I have at work, but within the next year or so I hope to be in a house so I can build a table big enough for a full sheet of plywood. Also I’m a noob with FluidNC, has anyone noticed when they jog 100mm after squaring an axes that it still shows zero, and anything after that the numbers move, but are still off by 100?

what part of Texas are you in?

You’ll need to provide more detail on exactly what you did. A video would be helpful. What do you mean by squaring? Do you mean that you homed the machine? Homing will zero the machine coordinates but work coordinates can be an offset of that. Also, if using the WebUI, there’s a refresh rate that defines how often the status/position display is updated.

Houston

I misspoke, I homed the x and y axis and then jogged the y axis and the 1st 100mm jog stayed at zero. Each 100mm jog after that showed a 100mm increase, but was still 100 less than what it should have been.

What are you looking at that is showing you the position? How are you homing the machine? How are you jogging?

I can execute gcode to make it look like you are describing but I don’t know why you would do anything like that.

me too, in Spring. I’d be interested in checking out your setup before I commit to building my own.

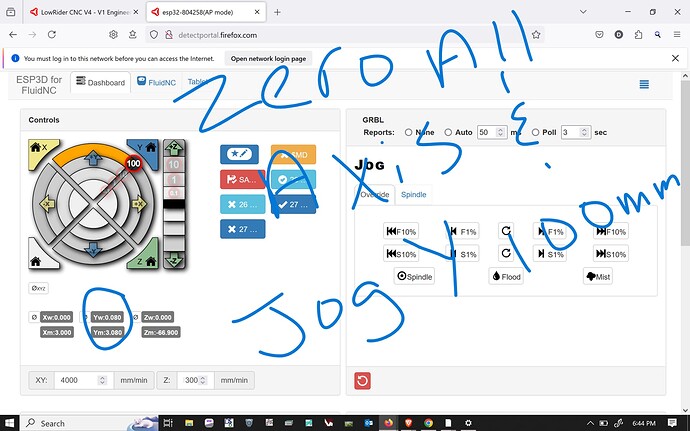

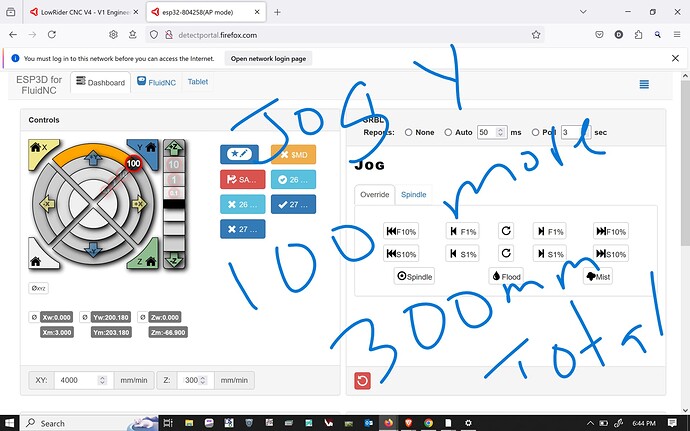

Ok, I took some screen captures and made notes on them to describe what im seeing. 1st image is homing all axis, and jogging Y +100mm.

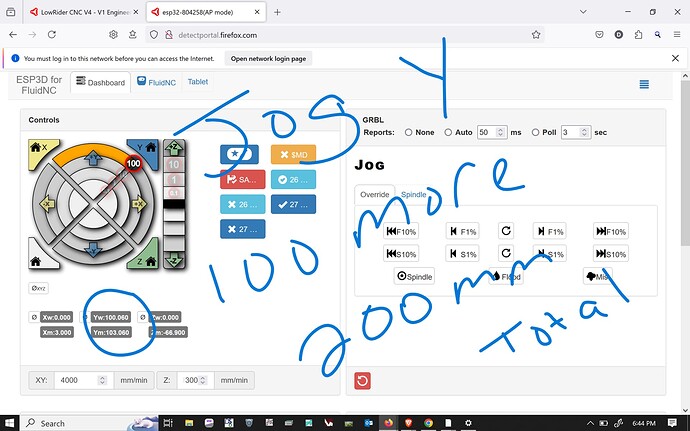

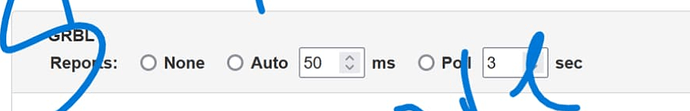

2nd image is jog an additional 100 for a total of +200 in the Y direction.

3rd image is jogging an additional 100mm in the Y direction for a total of +300

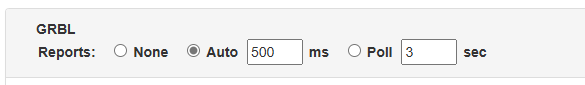

Oh, you just need to select a Report option. I’m not sure how you don’t have anything selected.

The behavior you are seeing is consistent with the “None” option. Basically, it’s not reporting the status so you’re not getting the updated position accurately.

Thank you! I was beating my head on the wall earlier trying to figure out that, and a few other things. Could you shed some light on why my Xm and Ym are 3mm more than the Xw and Yw, and what Xm, Ym, and Zm mean? Sorry for all the questions, the FluidNC wiki doesn’t have much info on the webui side.

Sure. Xm, Ym, and Zm are machine coordinates. When you home the axes, these get set to zeroes. Xw, Yw, and Zw are work coordinates. These are offsets of the machine coordinates where you do actual work. When you run a job, you typically jog to where you want to start it so that it reflects the origin defined in the CAM software. You’ll typically see a G92 X0 Y0 command which zeroes X and Y in work coordinates. Then you probe for Z to set the starting Z position. In other words, if you home the machine and then jog to X100, Y100, that’s the position in machine coordinates. When you run the job and the G92 command, now machine coordinates is 100, 100 but work coordinates is 0, 0. In general, you can kind of ignore machine coordinates.

Ok, that makes sense. I am coming from the LR2 so I didn’t have any limit switches, I usually just set my X and Y zero to the center of my work piece. Thanks for your help!

Sure thing, I am downtown in the Med Center though, and only during the week.

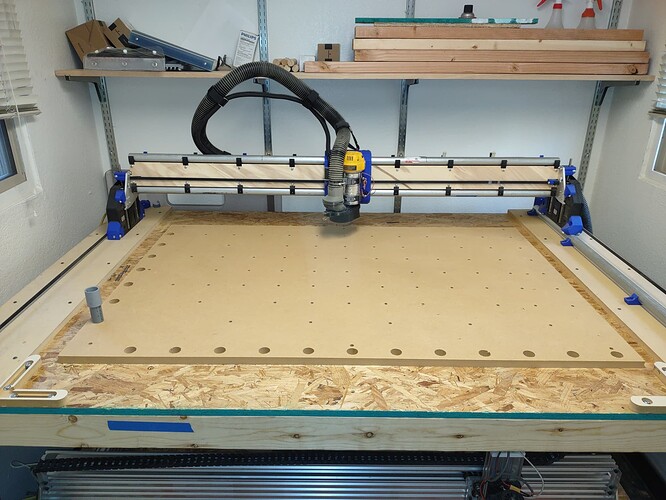

Getting closer to game time! I made the spoilboard in Aspire, and I also figured out how to turn the router on at the beginning of the job, and turn it back off at the end of the job(although I’m sure someone already figured this part out). Router has been trammed as well, I just need to fix a hole on my vacuum so I can surface the spoilboard, I made one heck of a mess drilling all of the holes, but on a side note the dust collection work exceptionally well!

I really like your build!

Thank you! There are quite a few builds that are far more impressive than mine, but I am hoping to finish up and actually start making things!