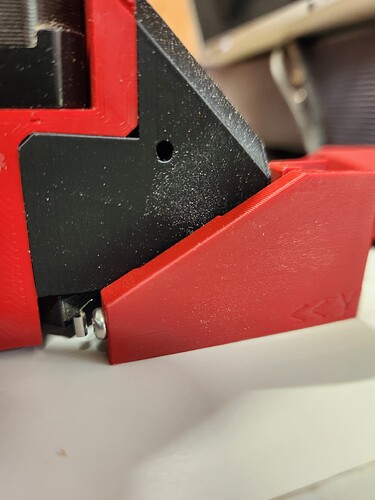

I am working on building an LR4 from my primo. I am confused on setting the rail and belts. On the side without the rail, the end stop lines up with the screw on the y-belt holder, but on the rail side the screw is about 10mm too low. What am I doing wrong?

Nevermind, I just realized the rail wasn’t snapped in to the clips.

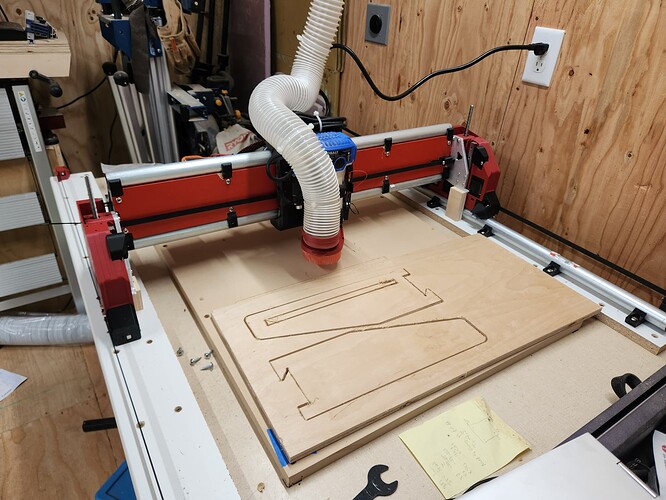

This LR4 thing is great. Compared to the primo, the build went really easy. I also got a bit lucky in that it was square without any adjustments except I moved a z endstop ~1mm. XY was within 1mm to the best of my measuring ability.

The main reasons I upgraded were:

- larger size

- dust collection

- ability to use table when not using CNC in small shop

This has met all of my goals so far. Here is my first almost successful cut. I messed up grouping the tool paths and tried to go back and cut the center out with only tabs holding it together and it lifted up. Note there are not chips or dust. Amazing!

I am having some vibration in the +Y. It does not seem to be affecting the cutting, but it definitely is different in this direction. Here is a video:

Is this normal. This is cutting mahogany at 6mm DOC and 1000mm/min with a 2-flute 1/4 end mill.

Is the core tight on the x rail? How tight/loose are your y belts? That actually sounded pretty good to me though. I’m curious what the others have to say.

Go faster and less deep, also it sounds like the endmill might be really dull. ![]()

The bit sounded like this out of the package. It is a Whiteside, so should be good.

I thought the general advice was to go deeper, not faster. What are typical DOC and speeds for LR4? On my Primo, I was running at 800mm/min, 4mm DOC.

Good idea. I can’t feel any movement, but I have not retightened anything after I built it, so it may have loosened up some.

I go 2400mm/min with 4.5mm DOC and 24k RPM with a 2-flute 6mm endmill. DOC has a way higher impact on the load than speed.

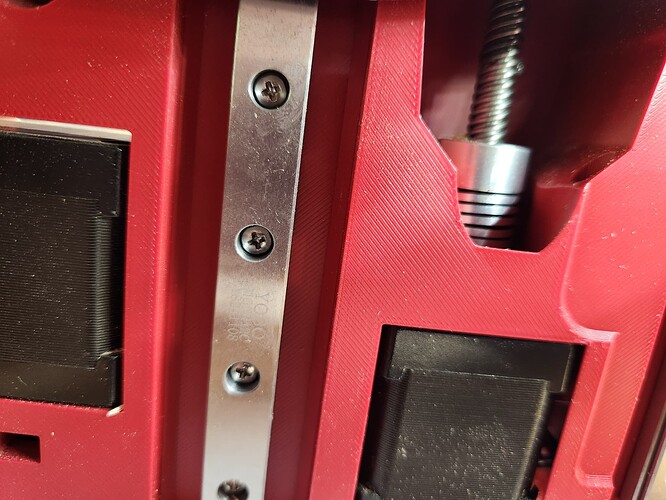

Hi All, I have a couple of questions. First, I finished a job yesterday and went to home Z so I could park it and it failed. The Max side binded, stopped or something, but did not hit the end stop. When I looked at it, the coupler was stretched. Not sure what happened. Is this a problem, and if so, how do I resolve it?

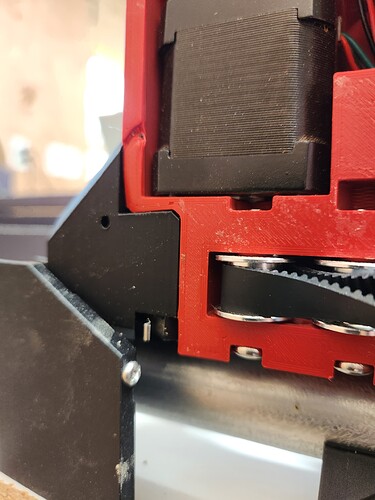

Second question: How much of a gap should there be between the gantry and the Y-belt holders? Mine seems very tight and sometimes when I home, one side will not clear and it will bind, skip steps and fail homing.

You mean between the xz plate and the yz plate?

The trick with the xz plate is to first loosely attach the linear rails so they lay parallel then move them and tighten things up in steps so you can verify movement isn’t binding. Nothing should rub. Your gantry tubes should be slightly shorter than the struts so they dont stick out. The xx and yx plates should all be parallel or perpendicular to reference planes, not at random angles.

Not sure if that gets you to a quick fix, but hope it helps.

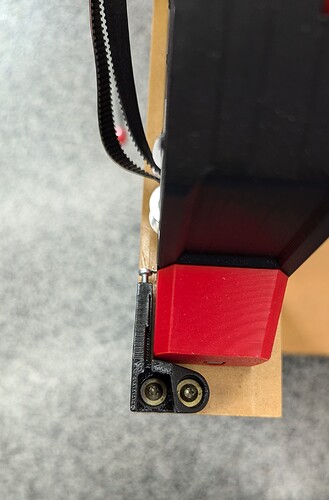

No, I am talking about the outside of the YZ assembly and the belt holder. I inserted the picture from the build docs. The gap here needs to be small so the screw will hit the endstop, but double thickness of belt also goes in there also. Recently I have been manually moving the gantry to the endstops and then backing it off slightly before homing to prevent it binding.

That one is pretty normal. The coupler should not and normally can not stretch since the weight of the gantry pushes it down. If it does the motor is turning and the gantry not moving. ![]()

grub screw?

No, some sort of binding like mis-aligned linear rails or a jammed carriage block or jammed gantry. The screw is turning and getting pulled upwards (stretching the coupler) as a result of the gantry not coming downwards.

If it’s moving freely now, it might be ok to use for your purposes (or it might not be)… the coupler is meant for compensating for axial mis-alignment, not for springing… it could be too sprung to hold position. ![]()

If it’s still bound up, fix the binding and try it out. It may be ok.