I’ve noticed a problem with my LR4, doesn’t appear to happen when cutting but only when drilling. When drilling, when the Z height gets low, the side sections (which run along the rails) lift up. It doesn’t look like anything is contacting the cutting surface (the dust boot, the collet or the bit).

Anyone have an idea what would cause this? Its making my drill holes non-circular…

What tooling are you using for ‘drilling’ operations, and using what milling strategy?

What’s happening is when your machine is ‘drilling’ is that the machine isn’t. ![]()

Instead of cutting, it’s just pushing up on the router and lifting up the gantry.

Aside from messing up your holes, this will really mess up your endmill as well and might even make things hot enough to risk starting a fire.

Just using the ‘drill’ option in estlcam.

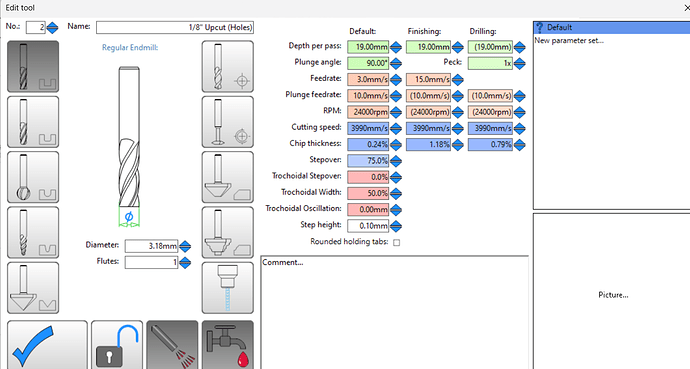

The bit settings are below. Its 18mm MDF, set to cut to 19mm depth.

Jim kind of said it all: endmills are not good for drilling. You can see them turning black after a few holes pretty often.

Ahh I get it. Of course, its flat on the bottom not tapered like a drill bit. This never occurred to me.

Can I just put a standard drill bit in the collet for the drilling operation then? like a 3mm one?

Yup.

I have special endmills that look look like a fish tail, so you can semi-well drill with them. I bought drill bits though, just works better.

If you want to do holes that are a little bigger than your endmill, you can try helical. Works well. ![]()

The ‘Holes’ work fine with the endmill, as the holes are slightly larger. Around 4mm.

Its these small 3mm holes that were causing the problem, as estlcam wont let me select them as ‘holes’ as they are smaller than the bit size, so i had to select drill.

I’ll just use a drill bit and set up another operation with a tool change.

I’ll try some more cuts and report back. Cheers lads.