Build Log entry #4: Bootstrap

Just a few notes. Thanks to several members here, I’m putting some “finishing touches” on the machine both cosmetic and functional.

- Jason Yeager’s FluidScreen shenanigans.

- Doug Joseph’s Panels, modified 2-wrench dust shoe

- My son’s WLED controller (his first PCB design) running “Musings”

However the big point of this post is that I had one of those “don’t leave your machine unattended moments” this weekend, and I was right there to kill the machine before a fire started. I love the LR4, and I’m simply noting how it happened and what I did to temporarily fix it. I’ll be looking at more permanent measures when I replace the temporary struts.

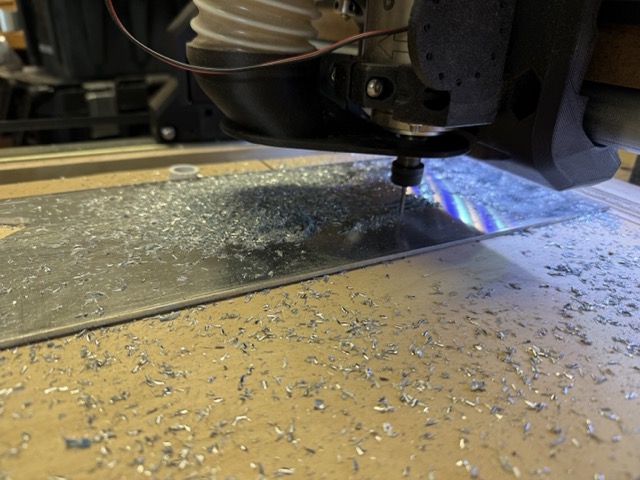

I was doing my first aluminum cutting this weekend. I needed to work out feeds and speeds (and z-flatness), so I decided to start by cutting some Peter Plate covers out of some scrap I can buy by the pound. During the cutting of the second part, the machine suddenly dropped, lost connectivity and was DOA. Unfortunately, in my temporary setup, the spindle is not yet hooked through the E-stop, so I had to kill both quickly. No fire - whew.

What happened? Well, initially in the aftermath I could not talk to the ESP32 at all while it was on the Jackpot. But when I removed it everything appeared normal. I was describing my frustration with my son when he said “it sounds like something is shorted on the Jackpot.” Then we walked into the garage and he said, "Oh, I bet you had an aluminum chip land on the Jackpot and short something. (Then he turned around and went back in the house ![]() .)

.)

I used some canned air and carefully cleaned the Jackpot off, then tried again and sure enough it worked! The gap (necessary) between the bottom strut and the bottom rail had allowed aluminum up to the control board area. I have Doug’s panels installed, but I need to figure out a solution to the Jackpot bracket to better protect it from the debris generated at the cutting area.

Moral of the story - don’t leave the machine unattended.

Chip size at 15000 rpm and 5mm/s with 5% finishing pass on a 1/8 end mill. (Not trochoidal.) I’m still not happy with the cut quality and finish, but it’s my first attempt. The parts are useable but not cosmetically acceptable yet. I could try trochoidal milling still. (Note there are also some marks from an attempted chamfer to give it a more finished look. I think I’d need to flatten the spoilboard to have it look good. I also changed the tool definition a bit which helped a little.)