When I started my LR4 project, I wanted 4’ x 4’ cutting area. My workshop is also my garage, so it needed to be storeable.

My plan was to build a table similar to Portable Lowrider in Annapolis. Micheal Cunningham’s requirements and design fit my needs very well. Then I discovered that a 4x4 table could not cut its own struts without some finesse. Being a noob, I didn’t want my first cut to require finesse.

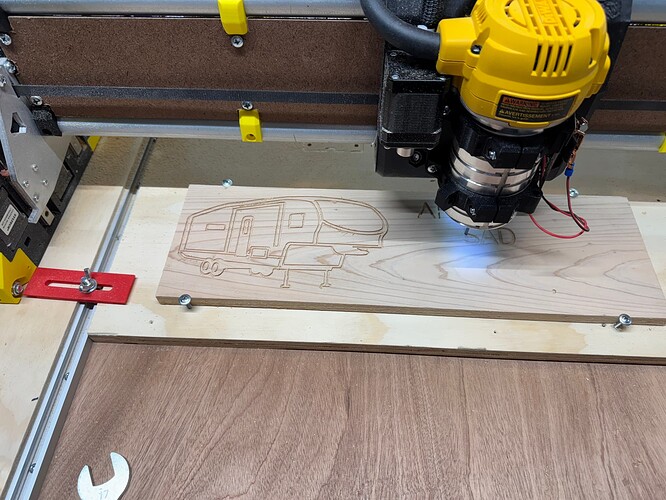

I decided to build a simpler table, as phase 1. The main structure is a 36” hollow core door. It has two plywood rails and sits on saw horses. The door is basically a torsion box. It is pretty flat and stable. The cutting area is approximately 2’ x 5’.

Pros: cheap, square, easy, and light. I think it will be ok for most of my projects. It will also cut struts for a 4’ LR4 (my Phase 2). And, it will serve while I learn and decide what I need. Easy to store. Only takes 5 minutes to setup the table and LR4.

Cons: The door skin is pretty thin. The rails screw into the border frame of the door. Attaching the spoil board was a challenge. My solution is a pair of T-tracks with lots of screws. So far, so good. I use screws to fasten the work piece.

The LR4 has a Jackpot controller. Dewalt 611 router. The Fluidnc pendant. I am still in the watching every move stage, so have not spent much time on dust collection.

Learnings: l like the Fluidnc web interface except for two things. 1) The WiFi in my garage is strong and seems to fight with the Jackpot in AP mode. Lots of latency and dropped connections. 2) The jog function needs a high/low speed selector. Jogging any distance is slow. I solved those issues with the pendant. The pendant is great.

I am jealous of you guys with room for a fixed full size table. Some of the forum table designs must need a fork lift to move. Some of the spoil boards are works of art. (Seems like a lot of effort for something that will be spoiled.)

My table and spoil board is minimalist, but meet my current needs. I still want a 4x4 table, but no rush.