I’ve just started building my first CNC, a LR4. I got through most of the core assembly, pushing the bearings in despite tightness based on reading other build posts. (Channel locks worked great, whoever suggested that). They all spin fine (one of the bottom ones is slightly tighter than the rest, but only barely.)

Now though, I’m attempting to fit the belt idlers into the core, and they just will not go in. Channel locks are now useless due to the geometry of the Core part (slanted backside from where the Idlers go in).

Are there any tips out there for getting those in? My core print wasn’t the cleanest part I’ve ever printed, but so far everything else has fit tight but well, and I don’t want to reprint if I don’t have to.

Thanks for your feedback in advance!

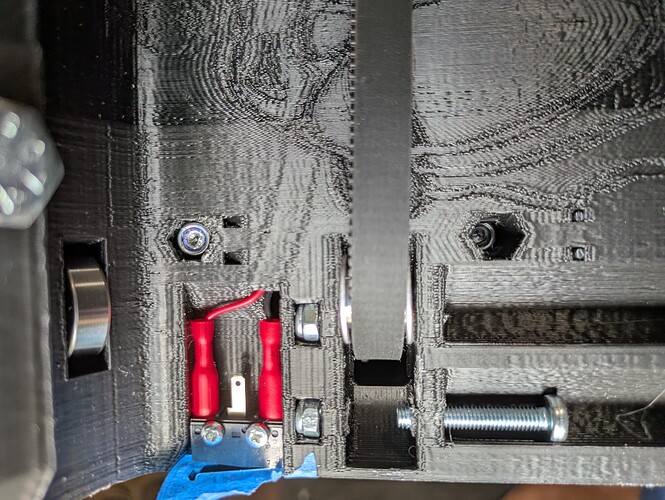

Can you post a picture of what this looks like on your print?

Depending on what issues the print has, it may be very difficult. The picture would help us see what you might be up against.

1 Like

Use a c-clamp and see if you can snug them in.