Has anyone built or have experience with both of these? Im working on the LR3 right now and see its a totally different design than the primo. Is the primo more rigud than the LR3 with it only riding on conduit on one side? I cant find many videos on the 3 to learn about its possibilities.

I think there is a couple ppl that have both, I have a nominal size primo 1”od tube and it’s great and ridged.

I wanted the ability to do larger things like a full sheet of Eva foam pad. So rather than build the primo to a large size ( isn’t recommended) I chose to start building a lr3.

There is some differences like z height etc

I am still very new to all this so I can’t help as much as some will be able too.

I am sure someone will chime in that has both working and will have a better idea.

Ive seen 1 or 2 videos about doing aluminum which i definitely want to try. Im just curious on how sturdy the 3 is with only riding on 1 rail. Does the belt only side lift off the table?

There is a thread that compares the speeds and rigidity, the LR3 does as good as an MPCNC. I myself am just switching to the lowrider, because it is still very accurate, which is really important to me if you look at the earrings I made (go look at @Neilp bee!) and I wanted to have more workspace to be able to work with 60x120 sheets of plywood that is a standard size in Germany. The MPCNC was just too small. I also don’t really love the pipe right at the front. It’s a brilliant machine though.

LR3 rests/sits on the rail, it’s not clamped. So for me, the rail side can lift if the machine is not squared and/or other situations. I haven’t seen the bearing wheel side lift providing chips/debris are being deflected/cleared/vacuumed. Some folks have built LR3 with rails on both sides, but my limited understanding is that increases chances of lift/inaccuracies? Slower deep cuts seems to be recommended way to maximize overall volume of material accurately cut/carved.

Curious if anyone’s modified their LR3 to clamp onto the Y-axis preventing lift.

The job of the rail is to keep the LR3 in the correct absolute position in X. If you have two rails, there is no room for error. Anywhere the two rails get closer or farther is going to lift the LR to make it fit. One rail is good, two rails is over constrained, and worse.

The router is heavy. The gantry is heavy. The bit is pulling into the workpiece. There should not be any lifting going on.

The true answer to the original question though is: These are both very capable machines. The LR is on its third major version. The MPCNC has at least 4, but the first version came with a lot of incremental improvements without a new major name.

You can’t expect a sub $10k machine to perform well on every material in a massive cutting volume. But with a LR3, you can cut aluminum. You can cut sheets. What isn’t clear is, can you cut aluminum on a machine sized for full sheets? If so, is it possible for a novice to do that? Or just an experienced user?

The LR3 is great. Build it to spec (or smaller) first. After using it a little, you will know a lot more about what you want to finish, and what the limits are. Then you will know better than anybody what your next step is.

I’m really hoping someone with a 4ft LR3 will see the video of Tom’s cutting alunimum and try to get after it.

I agree 100% that it’s really not clear just how much of that performance will remain at scale, but i think it will surprise a lot of people.

@KMRDesigns none of those things contribute weakness to the lr3 design, so you can feel pretty good about that. As for comparing the two, maybe this will help?

My primo cutting clamps at what I thought was a very respectable pace.

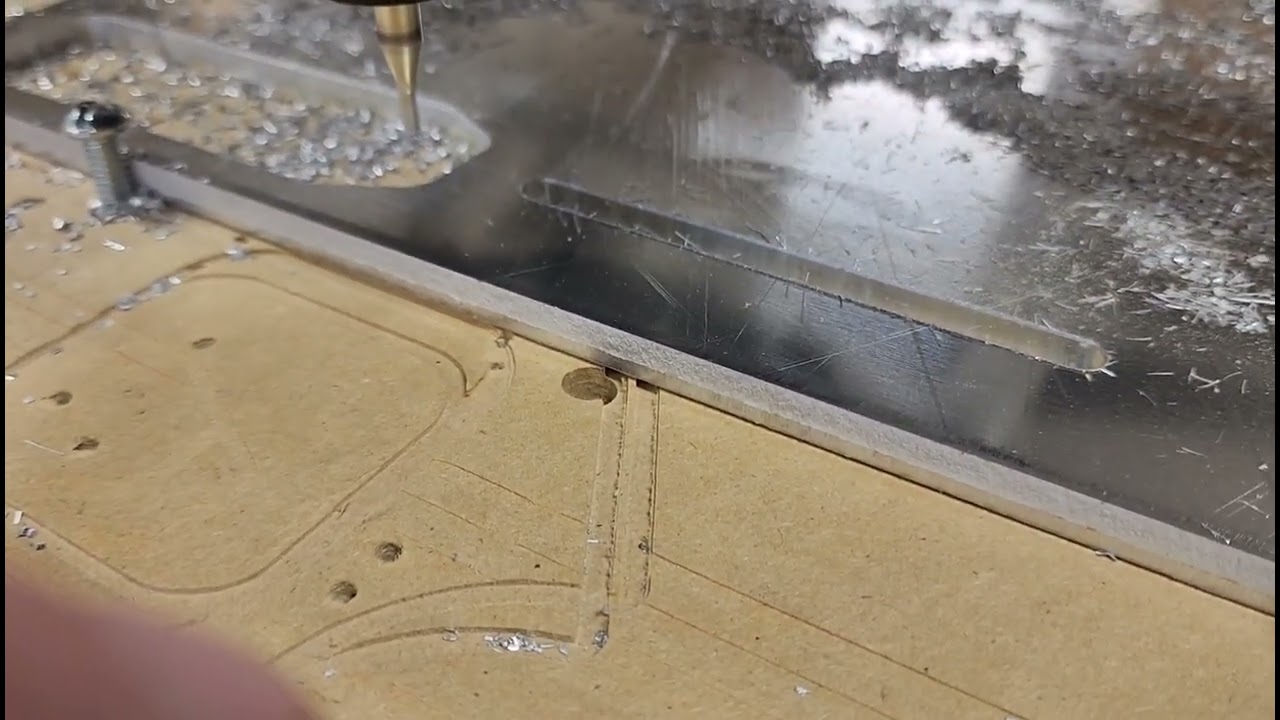

Tom’s LR3 cutting the same clamps, but at full thickness and not shaving them down first.

Tom turning up the heat on those same clamps

Tom using a 1/4in endmill on aluminum

Now, the sizes were comparable and I stopped pushing my primo at what I thought was a really good rate. Experience with the burly told me where to stop, so maybe it was way too early, I’ll never know.

But compare the first two of Tom’s videos there. I’d be lying if i said I knew what kind of performance you could get on a larger lowrider, but I would be really shocked if you couldn’t at least keep up with the first video.

Since you’re already building the lowrider, I don’t see any reason to worry about leaving performance on the table. My guess is that you need a larger machine, hence the choice for LR in the first place, and we have plenty of experience that says the primo is somewhat harder to run at larger sizes.