Is there anyone Who want’s buy litle project?

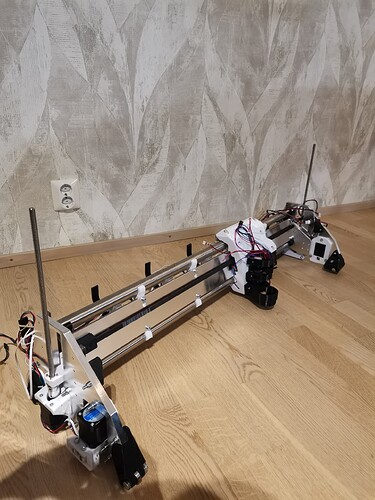

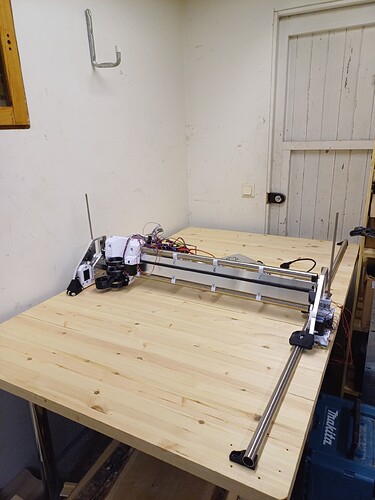

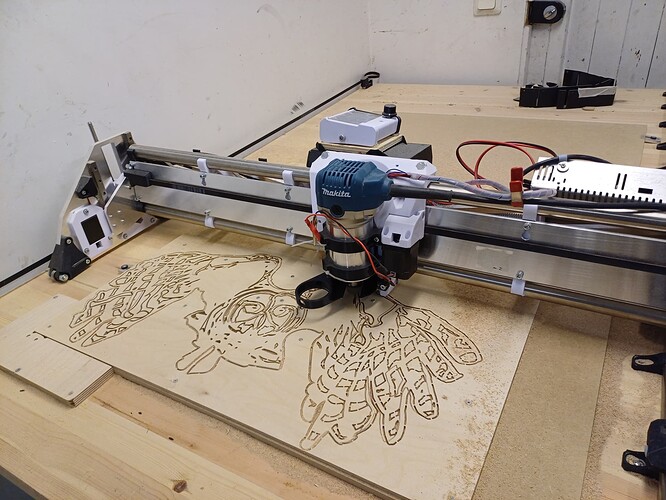

Almost ready lr3 build. All flat parts are made from aluminium. Tubes are stainless Steel. Rails are 930mm x 1636mm. Ready for makita router, but spindle not includet.

Table not ready but, there is included solid massive pine plates and stainless steel legs.

it is assebled Gt2 20tooth pulleys so you need fix marlin configuration. Few endstops are missing. I wish I could have more time… Location Finland so I dont send it. 800€. Kysy lisää.

It looks amazing. ![]()

Thx:smile:. I like it too, but it looks like some insect with those antennas ![]()

That is a really lovely build - I hope someone buys it and truly appreciates what they are getting for the money!

Okey not for sale anymore. I did squeeze more time and it is so close so I just can’t stop now. Could someone help me with marlin?

Specs:

BIGTREETECH SKR PRO V1.2 32 Bit Control Board

BIGTREETECH TFT35 E3 V3.0

5pcs Nema 17 Bipolar 59Ncm (84oz.in) 2A

Gt2 10mm timingbelt

3pcs Gt20 tooth pulleys

2pcs T8 screws 2mm pitch and nut’s

If you have the tft I find the touchscreen interface more intuitive than marlin. Have you managed to get the board flashed okay?

I flashed both, but my problem is pulleys they are 20 tooth and in original version they’re 16 tooth. How do I fix. yea I know in somewhere configuration I can do it. I don’t know how to use platformIO

I know I said it above, but I’ll say it again - that’s a really lovely build! I think you have convinced me to use solid aluminium struts too.

I could be mistaken, but I think that kind of fix does not require any kind of firmware edits in platformIO. I think all you need to do is change the E-steps, which I think can be done on your touchscreen. Someone who knows Marlin firmware better than I do can correct me if I’m wrong.

That would be great ![]() One solid strutplate (930mm 6mm thickness 5083 alplan) weight 1.3 kg. So I have only one solid plate and others are cut

One solid strutplate (930mm 6mm thickness 5083 alplan) weight 1.3 kg. So I have only one solid plate and others are cut

Okey thx. I’ll try that first👍🏻

Or… I could stick to my guns and use composite with an aluminium face! ![]()

That’s great material. Easy to machine

You can set the steps per mm with M92:

M92 X80 Y80

That should work. If it looks right, save it to EEPROM to survive a reboot with M500.

You should know that 20T pulleys will reduce the torque by 25% over 16T pulleys. So it wouldn’t hurt to order the right ones for use later.

I don’t like to “overfit” the steps per mm. So I wouldn’t mess with 79.9 or 80.1 based on measurements. The number 80.000 is perfect as long as the belts are exactly 2.0000mm pitch. I am more likely to have an error in my measurement.

Okey thx,are the steps per inch without changes? I’m aware of the torque, I think it would be only “engraving” machine, maybe later some milling after I see How it works

I don’t know what this means, sorry. Maybe I have had too much sun today.

Marlin only uses millimeters. If you send M92, it will tell you what the value currently is. It should be X100 Y100 Z400 unless you have a RAMPS or something.

Not for sale anymore.(has been ready from last summer) How do I delete this conversation? thanks for all who helped me.

I moved it to Low Rider → Your Builds. You should be able to edit the original post to either remove or rescind the for sale language. ![]()