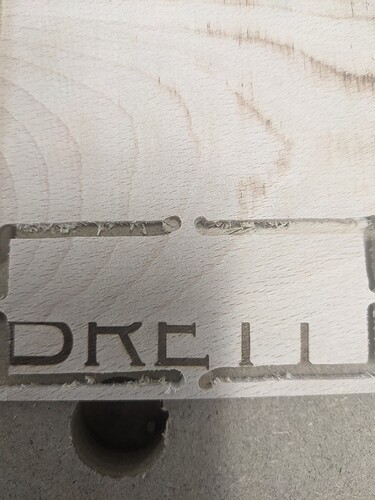

Just getting into CNC and finished a Lowrider V3. Finally finished the table and cut the spoil board with multiple bench dog holes with it and it seemed accurate. I’m working on lasering and then cutting out name badges in 1/8" hardwood, which I figured would be an easy first project. However, whenever my machine comes up or plunges at a tab, it veers off a bit, but then straightens out. I’m using Estlcam, 1/8" bit at 20 mm/s feed rate. Attempted to do a slow deep cut to see if that solved anything, but it did not.

Check your core. Are all of the bearings making contact with the rails? Might need to snug up the tension just a little bit. Very slowly! Its easy to over do it

Also make sure the router mount is tightened as well as the router itself.

I agree that it really looks like something is loose. I know it’s hard when you’re only able to evaluate your own machine but a lot of those lines don’t really look as straight as they should be.

When I was troubleshooting something similar, I also used my phone to video from different angles focusing on the core. I could tell the lower core was flexing toward y min in my case which left my cuts wandering a bit. Yours does look a little different so it is likely a different part that’s loose.

However did you move the workpiece between laser and router? The lines aren’t parallel. If both were don’t on the LR then that may be a separate thing to track down. Could be significant if you did laser it elsewhere but squared it up before router.

The lower bearings definitely needed some tightening and it improved it greatly, but it was still doing it. I put a new bit in (the one I was using previously spent quite a bit of time cutting MDF) and now it’s almost perfect, though maybe can be dialed in a little bit more.

As for moving the piece, the laser on that piece was a whole different test project. It just happened to be the scrap I was testing on.

Thanks for the help!

Dull bits can for sure cause lots of problems! They never last as long as we hope they will LOL