I’ve come across this topic in the MPCNC forum but wanted to bring it up here. I’ve done 3 nice projects with the LR3 but the last two don 't seem to be going so well. The first issue came up with the routing of Brazilian cherry. At first it looked very good with the cutting. I walked away and came back to see the 1/4 end mill stuck in the cherry and the router sill spinning and following the programmed tool path. When I reset, and tried a second time, the bit started cutting lower and lower. You can see the change between the pockets where the bottom gets thinner and thinner eventually cutting all the way through. So now I’m thinking that the bit is slipping. This project is ruined so off to the next. I’m using a Binstak 1 1/2 surfacing bit to surface hard maple. My cut depth is set to .7 mm and my feed rate is 40 inches per min and a 40% step over. RPM is between 1 and 2 on the Makita router. Halfway through the about 10 or so passes in, I notice the bit is cutting a little deeper than the pass before leaving a ridge. 3 or 4 passes later, it looks like it cuts just a hair deeper yet again. Starting the next layer .7 mm deeper, it gets half way down the first pass and then tires to bury the bit into the maple. I do the emergency stop and notice the router is very hot. I also notice that it now slides up and down in the core. I’m using the new tool mount with the cam. I try and tighten up the tool mount so tight that the mounting screw snaps the ring. I don’t think the tool mount became loose. I think the heat from the router caused the plastic to loosen??? I checked the brushes and they are 10.5mm thick. Am I cutting too fast or deep or do you think there is another issue? I didn’t have this issue with the previous projects but those were cut on walnut.

My Makita router runs hot. Hotter than it seems others do.

One issue with running at a very low setting is that it reduces the Makita routers ability to cool itself with the integrated fan.

If yours doesn’t normally run hot, then maybe it’s possible that the it’s being overworked at that speed, and you may need to adjust the rpm or the feed rate to reduce the amount of heat generated.

Yea, this whole feed rate and RPM is new to me. Concept seems easy enough but putting it into practice leaves me a little puzzled. If I increase the RPM, that should get more airflow in the router with the internal blades. Then if I slow down the feed rate, that should be less strain on the router. But then do I run the risk of burning out the blade with more of a dust than chip from the wood? Perhaps I need a set of feed and speeds per wood type?

yes. Each wood type will have a different feed and speed… within reason.

I have pointed box fans at my MPCNC in the past to help keep the router and electronics cool while doing longer cuts.

Got pictures of that?

No. It was just a 20" box fan sitting on a stool pointed across the top of the machine.

For a while, I also used this to blow dust out the front of the garage door because I didn’t have a vacuum system setup.

I wonder if raising it on the mount will help? The airflow out of the router appears to be very restricted when dropped to its minimum - I haven’t actually checked the area of the outlet vs the area of the fan, but try raising it by a few mm and see if that makes a difference.

Actually try raising it by ten or fifteen mm to start with and then if that works drop it a bit until the overheating recurs.

In the stock setup as a router, the base has to be below the collet, and the opening for the exhaust is rather a lot more than the LR3 base allows.

The first time I used it and it got really hot, the exhaust softened that mount part and it deformed.

The problem is if it’s not bottomed out, the wrenches are hard to use, and if I remember correctly, there’s not much room to move it before the core will hit the piece before the collet.

Not that that is necessarily a problem, but it will reduce the usable cutting depth

Yep, I’m just trying to trouble shoot to see if that’s the problem. Wrenches (plural?) have I found someone else who doesn’t use the red button?

I can’t.

It’s too hot ![]()

I also feel like I can better limit the amount of torque I put on the router and mount with the 2 wrenches.

I can’t really offset the force just holding the button down

Curious which vac mount folks with hot Makitas are using? Reason…

Recently noticed Ryan’s latest vac mount for the Kobalt Router has an opening that lines up with a hole in the Core. Which I only just recently guessed is probably to help with router cooling/ventilation?

https://www.printables.com/model/628738-kobalt-router-lr3-mount/files

I don’t see this vent feature on the Vac mount am using for my Makita. Am currently using this 2-1/2" Vac mod…

https://www.printables.com/model/212623-lowrider-3-cnc-makita-700-series-mount-removable-d

Not sure if the stock LR3 Vac mount has vent hole feature either?

https://www.printables.com/model/167687-lowrider-3-cnc-blank-tool-mount/files

I wrote about it in another topic as well, I always use the wrenches because it‘s easier to not accidentally move the CNC during a tool change. ![]()

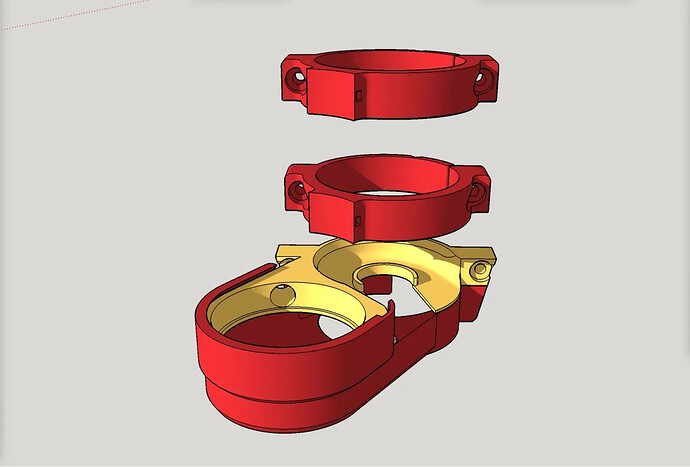

I will eventually be rehashing the mounts, because my 2" hose isn’t 2 1/2" and router venting is one of my theoretical concerns. I think a little more can be done to redirect the airflow as well, but until the “case of the overheating Makita” there was no reason to look further into it.

Don’t wait for me though. My current programme is pretty packed and my Makita isn’t overheating.

Wait… my Makita isn’t turned on. ![]()

I just modified my base. I had the same warping and I think it’s actually a combination of the heat and the Makita getting loose adding wight to that piece. I’m now tightening the mounting screws regularly as I’m finding them a little loose every 2 - 3 hours of use. Could be I need new lock nuts. The modification is just adding 1 mm thickness to the bottom and adding 1mm to the top of the inner resting ring.

Another thing that I was just thinking about….

I haven’t integrated my dust collection yet, so that hot air is not getting sucked away.

Maybe that’s the difference in why mine gets hotter than others

Its too widespread. I don’t see it too much on here about it. But when I was digging into the rabbit hole there was tons of threads that mentioned new routers seemed to be having heating issues.

Mine is ~3 years old and I’ve never had any problems with it. Would be bad if the newer version overheats, there has been a revision since.

Yeah this seems to be the issue and why it’s kinda hard to figure out. Most the threads had people that had no issue, some never noticed but did (aluminum mounts). Some though maybe the bearing manufacturers changed in between production (whoever has supplies) and the variance is just enough friction to cause issue. Others thought it was the brushes… etc, etc. most the thread unfortunately became screaming matches over why they didn’t buy a spindle with their $5k machine. Really made me appreciate the community here again.