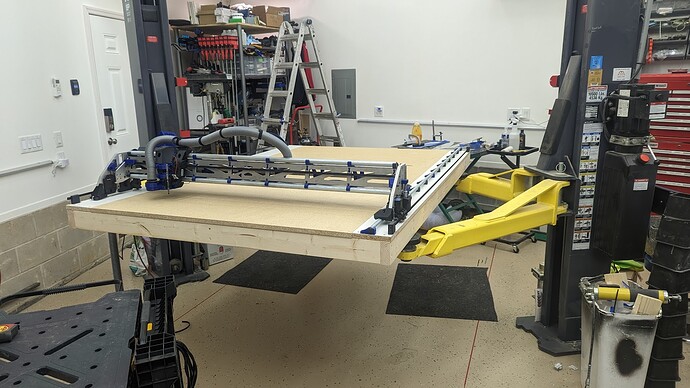

Ever see an LR3 on an automotive lift? Shop is very dirty sorry. Instead of making a fixed table, I made a modular table that I can take apart in 3 pieces and place on/off my lift when I am ready to use the machine. I only use my lift once every 3 months. I can also fully extend the lift and still park under it ![]()

It is in 3 sections. Total table is setup for a 4 x 6 sheet. So 29 inch sections x 3.

secured by 8 3/8 bolts into barbed T-nuts.

I figure this is a pretty great option for those who have limited space and/or want to move/breakdown their table from time to time. You can also put legs on if you want. I just don’t have the need bc of the lift.