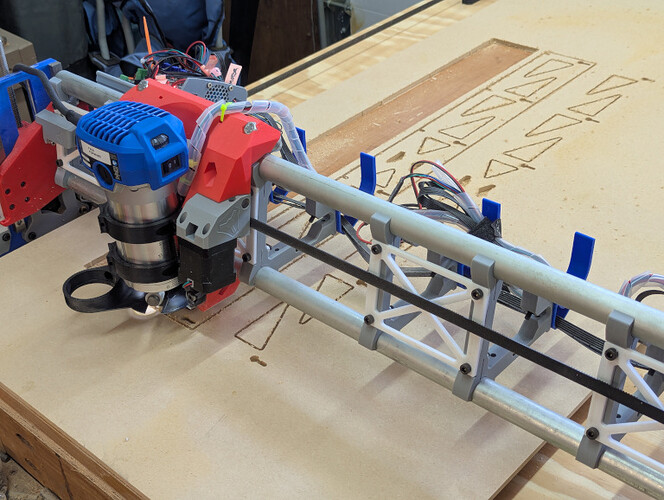

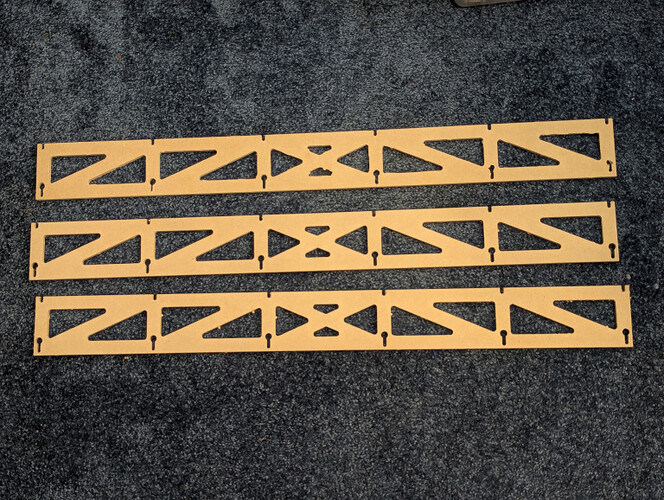

I began my LR3 build early in 2024, but it sat on the shelf for about a year after life intervened. I only recently got back to it, and this week marks the first time I’m using it to cut parts, starting with (of course) the strut plates. There was very little drama. The first one I cut a bit too shallow, leaving an onion skin on the backside. I also had it set to use full thickness tabs, but I consider that successful. The second time I cut two at once, and added 0.5mm of depth which made sure i’d kiss into the spoil board. One thing that I did notice was that it appeared that I had a minor shift in cutting the long sides. Not sure what the cause is, but the defect is cosmetic given the use case, so I’m not going to worry about it. If someone has any obvious hints for the complete newb, let me know. (Settings were 25mm/second feedrate, depth 1.2mm, speed was around 18Krpm. Cutter was a 2 flute 1/8" spiral upcut.) In any case, I’m having a lot of fun. Thanks for looking at it.

Any chance the material moved on the table? Some folks will set the job up so that a couple of holes get drilled first, then pause the job and use those holes to screw down the sheet so that it cannot shift. This also tends to avoid cutting through the clamping screws, since that part of the job is already completed.

It seems unlikely, as I screwed a spoil board down, and then screwed the MDF to that board using five different screws. The worst part of the cut occurred on the piece that was furthest away from the home position of the gantry, so it makes me suspect gantry flexure, but maybe something else was going on. Thanks for taking the time to give me a hint though. I’m thinking of installing the struts today (the minor misalignment won’t matter to their use) and see if I can get some better results.

Mine did something similar and I ended up needing to tighten the bearings on the core by 1/4 turn. However, you should check the grub screws to ensure they didn’t shift or settle.