I’m having an issue with the LR Core and the braces - I’ve printed 2 different sized braces (24/3 & 25/4) and both rub against the Core specifically the area shown. Any advice as to where I’ve gone wrong?

Cheers…Doug

I’m having an issue with the LR Core and the braces - I’ve printed 2 different sized braces (24/3 & 25/4) and both rub against the Core specifically the area shown. Any advice as to where I’ve gone wrong?

Cheers…Doug

Hello Doug! Don’t know if this’ll help any, but am curious to see problem cause and solution.

What Printer setup do you have? Asking because dialing in my printer dimensions (before printing LR3 parts) involved me printing and refining my calibration “esteps” a few times using Cura’s test calibration cube feature. Adding Dual gear extruder and adjustable tensioners to my Ender 3 Max seemed to help dimensions/reliability too.

Wondering whether printed Z axis is skewed and/or calibration is off. Looks like the backside of the ‘right’ side of the Core is colliding/rubbing, which has the top most printed layers. Do you also have the same contact/rubbing issue on the ‘left’ side of the Core which has the first printed layers?

If the ‘left’ side clears but the ‘right’ side doesn’t that may indicate Z axis is skewed on the printer. If both sides collide/rub the same, then consider (if you haven’t already) verifying printed part dimensions with calipers and/or try printing test calibration cube. To verify part dimensions, personally, I’d load the models into Fusion 360 Free and use the measure tool.

Am seeing ~1mm clearance between Core and 23.4 Braces for my build that uses 3/4" EMT from HomeDepot.

Using bearings from V1E Shop’s kit? Does your assembled core look something like this…

If not, maybe double check your bearing dimensions match V1E Shop’s LR3 Bearings 608-2RS – V1 Engineering Inc (14 needed for LR3)

Man i think award for most uniquely colored core goes to you!

Hi Aaron - I’m using the Prusa MK3S+ which so far seems accurate.

Might run the calibration to see if that’s the case.

Unfortunately I’m constructing my LowRider in my hangar which I won’t be going down to until tomorrow so I’ll check the side issue when I’m there…

Thanks for the info!

I purchased about 60 X 608 bearings and they seem to fit fine…

Hi Doug - I’m assembling the LR3 and I have the same interference you complained about.

I printed all the details with the MP3DP with a 0.6 mm nozzle

I too used 608 2RS bearings and the tubes are 25mm diameter (common in Italy)

Did you manage to find a solution or at least do you know where the problem originated from?

Your comment would help me

Thank you

Hi Gianpaolo - I haven’t really determined what the solution is. I printed with a 0.4 nozzle and it’s seems quite bizarre that no one else has this issue! If I find a solution I’ll definitely post it here…

Hmm, that is really interesting, as I am considering building a 25mm lowrider as well. I just don’t know whether there have been other 25mm builds yet. @Ryan do you know? With the Primo we had a problem with the core clamps at the beginning as well.

Do you have all 4 lower bearings in or just 2? That was the issue last time I heard of this.

Hi Ryan - All 4 lower bearings are installed…

Can you take a picture from this angle?

I can’t see how these would collide unless the bearing were missing or severely undersize.

What size tubes are those? It might be helpful to measure them exactly with calipers.

Not until Sunday sadly…

All 4 in the top?

I agree with Jamie though, let’s see some more angles. That is not normal.

No problem but not until Sunday

@Tokoloshe 's question made me curious. If I overlay the 25.4 brace and 23.4 brace and align them, this is the difference:

So it looks like the design is such that the points where the bearings ride are invariant to the tube size, and there should be a constant spacing between the core and the outer surface of the braces, regardless of the tube size, as long as the proper matching brace has been chosen.

If the wrong brace is chosen, then the upper and lower surfaces of the rails will have the wrong distance and the core will be very loose or very tight.

That makes sense, thanks Jamie and Ryan.

The tube I use, measured with the caliper is 25mm

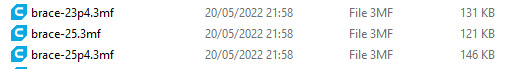

I looked at the files I used for printing

I tried to print a the brace-25.3mf and it seems to be more suitable than the brace-25P4.3mf I printed previously. Perhaps this is the problem and probably the solution is to print new brace-25.3mf

Can you confirm that please?

Thanks

Yes, the brace-25 file is for 25mm tube. The brace-25p4 file is for 25.4 mm tube, which is one inch outside diameter.