Note: Just giving this little pet project of mine a space on it’s own rather than hijacking other subjects

What is it?

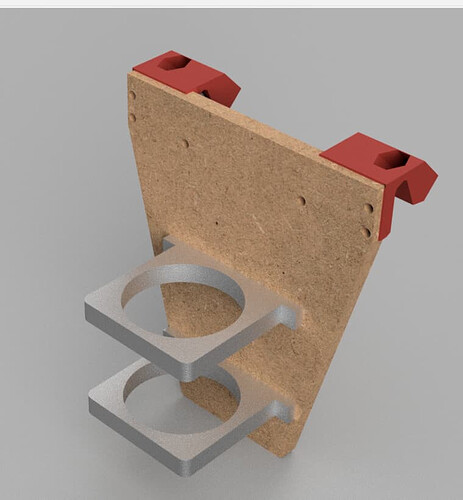

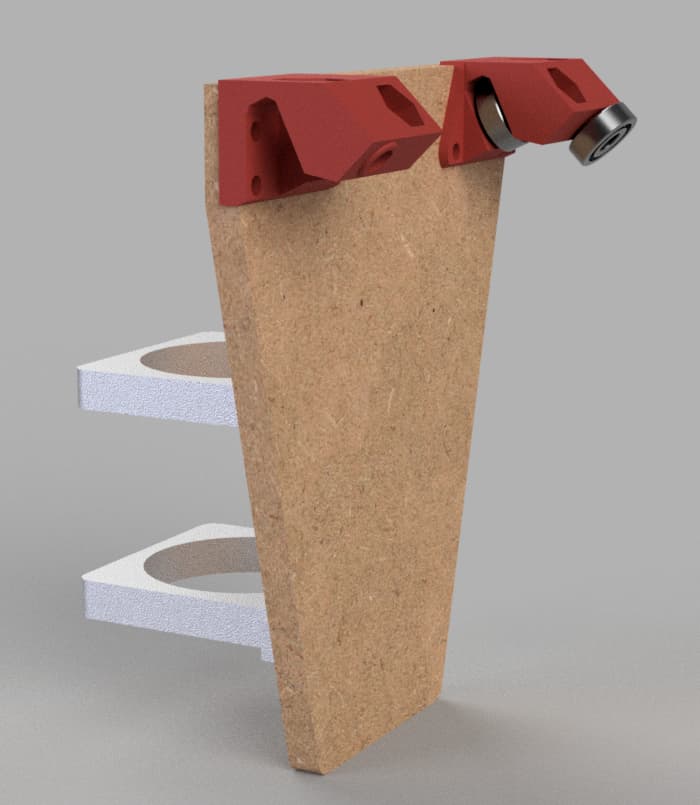

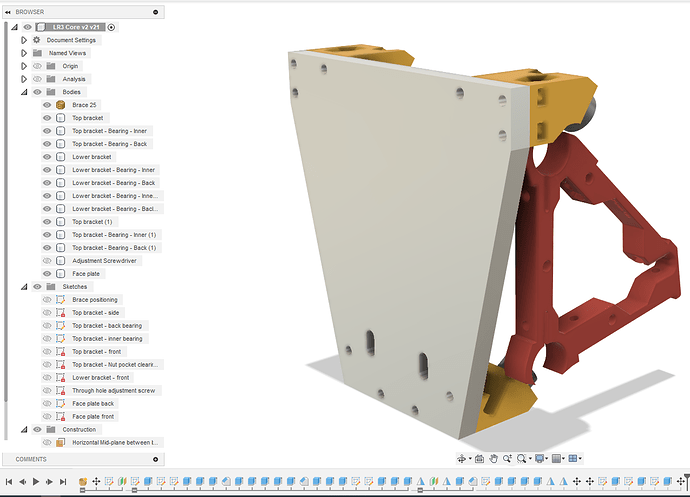

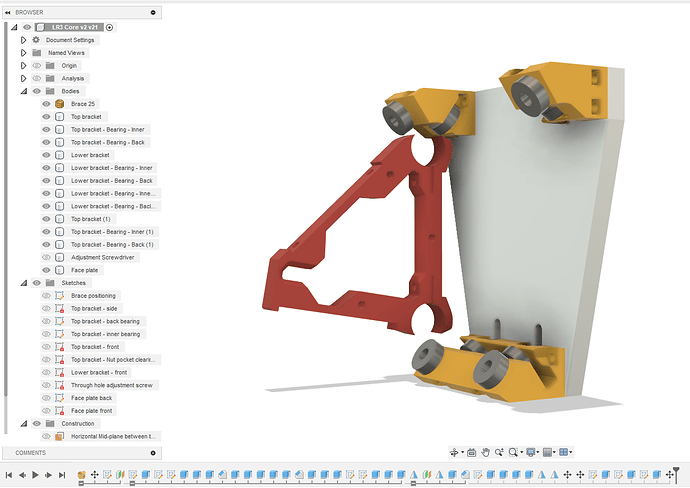

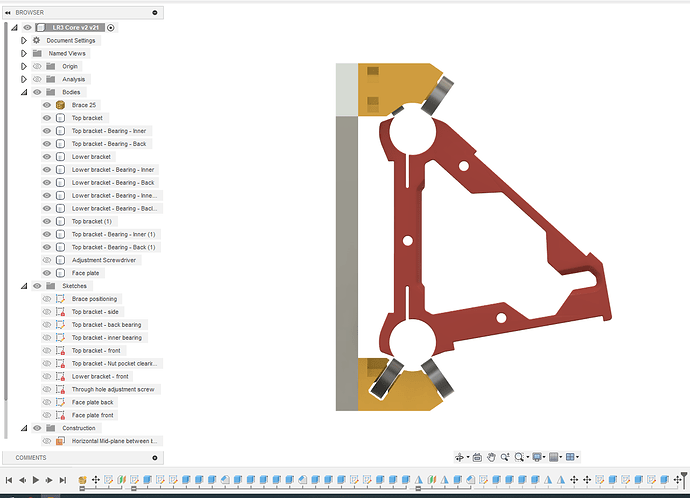

The basic idea is to replace the 3D printed LR3 core with a cnc-cut one and smaller 3D printed parts attached to it, much like the XY plates

But why?!

Hey, why not? ![]()

This is meant as an experiment, rather than an actual “upgrade”, but this kind of design could bring some interesting features:

- Faster/easier print (smaller parts)

- Flat-packing for shipping

- Customizable core width (eg: small cores for an idex build) and height

- Aluminum face platefor rigidity ?

- More conventional mounting for off the shelf accessories (eg using an aluminium clamp that’s been provided with your spindle, or a tramming plate)

What are the downsides?

There’s a huge one: the router would be hanging further from the gantry, thus increasing leverage and reducing rigidity

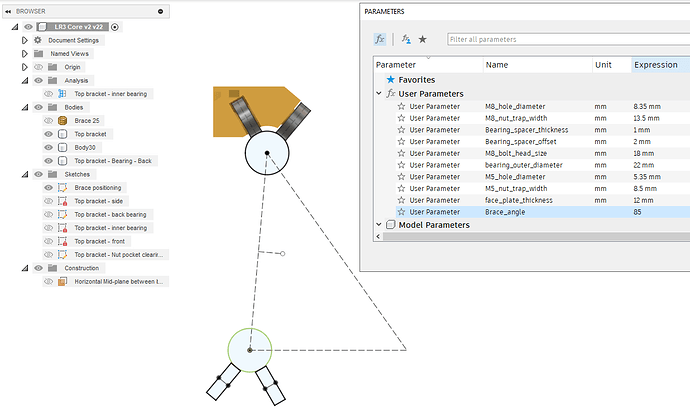

The initial mockup was something like this

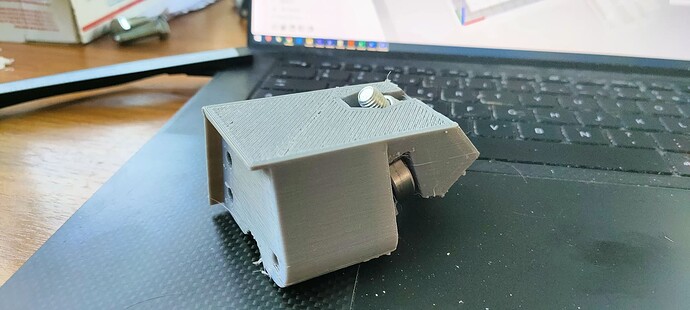

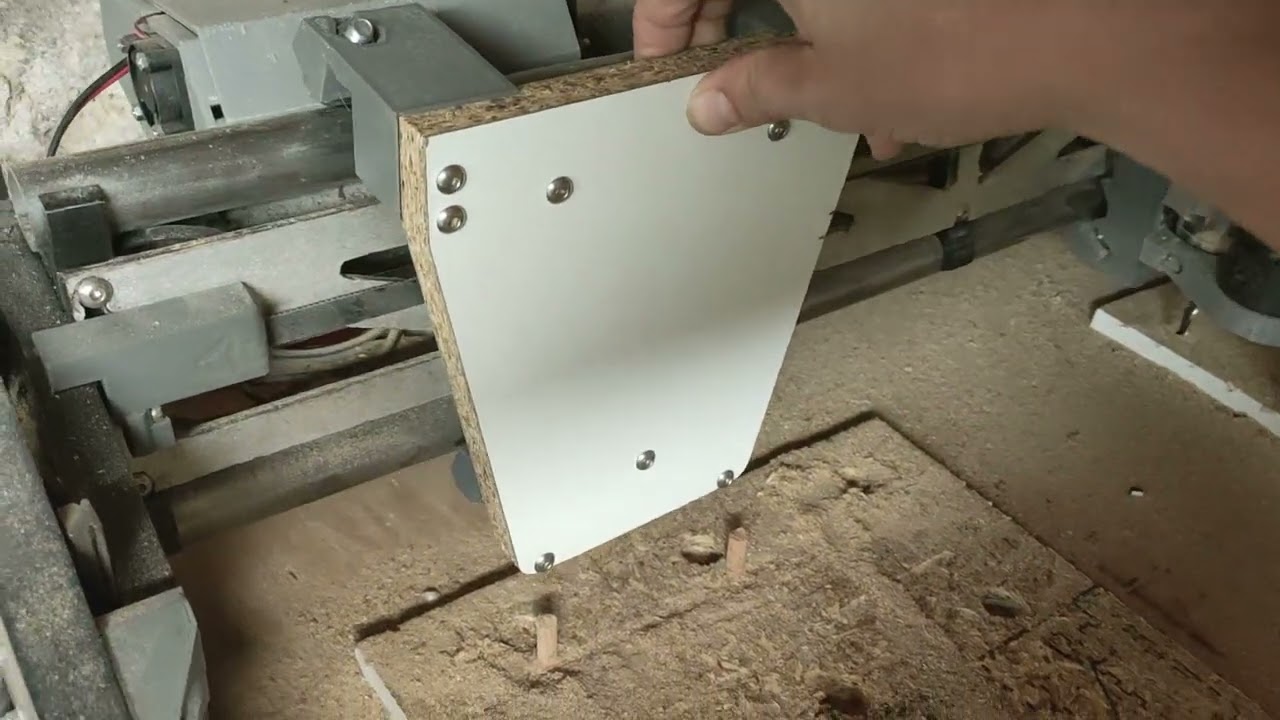

I already made afew first prototype prints and made a dry-fit testing

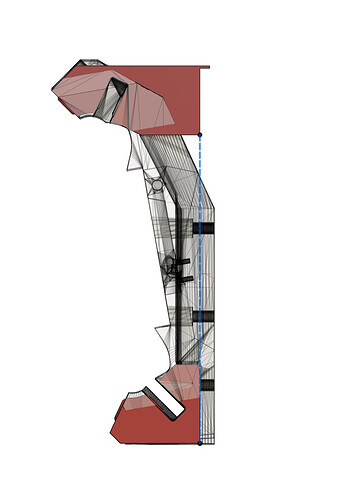

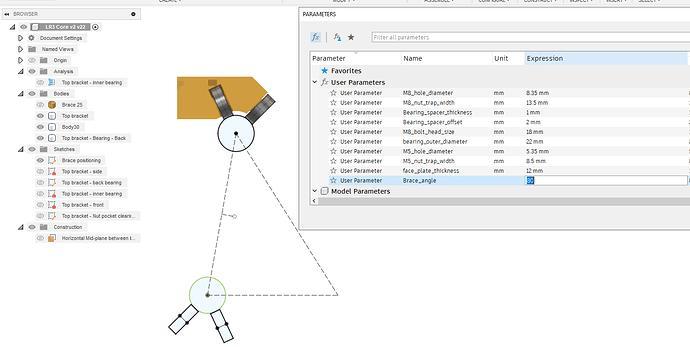

Currently I’m re-designing the whole thing from scratch as the first design was a bit sketchy

The design steps are a bit more streamlined and easier to work with

Also, I’m trying to make the tilt angle adjustable, as I’m tempted to experiment with a vertical strut assembly…

Don’t know where this rabbit hole will lead, but I’m enjoying the ride so far, pretty fun tinkering with this even if it’s probably totally useless ![]()