I’m building an LR3 with the goal of being able to cut full 4x8 sheets. Give or take a little, the gantry will be roughly 5’ long in order to be able to cut edge to edge.

When I think about this monstrosity, the issues are sheer size and being larger than standard sheet goods. I’m looking for ideas for a modular sort of table that can be broken down for storage and travel. I anticipate using the machine at job sites (schools, etc) so thinking about portability.

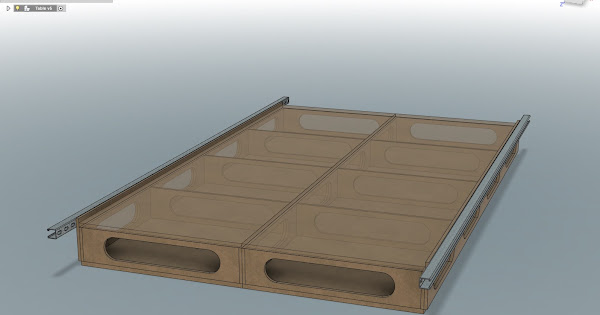

My idea is to make a one-piece narrow torsion table just for the Y rail, and another for the opposite rail. I realize I lose a lot of strength making it narrow and unconnected, but it’s about making a portable track. With just this, the tracks could be manually squared, screwed down to a work floor, and put to use. Not perfect, but for cutting large complex shapes for high school theater props, should work very well.

Improving this would be adding additional boxes to tie the two Y rails together and give a raised surface for the material. This could then independently sit on the floor or on horses.

Any suggestions on considerations I should consider?