I love my LR2, but one of the things that I wanted to change was the Y belts being out there for me to snag or bump - just waiting for me to damage them or yank the gantry out of square. I’m way too accident prone for that. I’ve seen several threads on this topic here and wanted to share my solution.

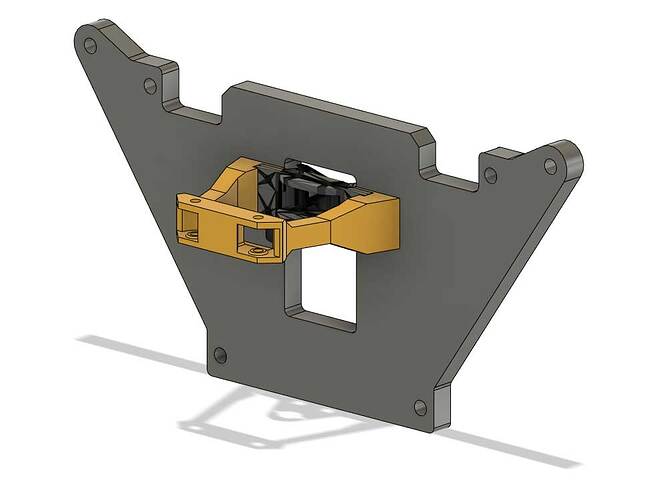

I made a new part for the Y plate assembly to route the belt to the inside of the strut. It uses the same mounting holes and fits around the y-axis motor mounts. It requires two more idler pulleys for each side and longer mounting screws, but no modifications to OEM parts. Have been using this for about a year and it’s held up pretty well. Only downside is that the Y plate assembly has to be slid it in from the open end of the super strut. The height, once screws and nuts for the idlers are added, is too much for this part to fit into the superstrut from the side ![]()

Another upgrade was adding rail on top of the superstrut on one side to keep my LR2 gantry from shifting around. The height difference required that, on that side, I flip the motor and belt-routing part upside down… still works great, just had to also switch the wiring to keep both motors pulling the same way. Here’s a shot of both sides - sorry it doesn’t really show the part in action. I couldn’t get a good pic inside there, but you can see the belt within the superstrut:

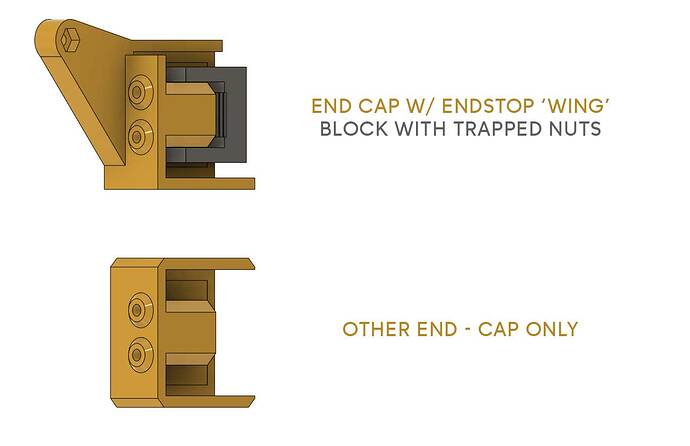

To hold the belt inside the superstrut, I made some end caps that have a block inside with teeth, and captured nuts which can be tightened to trap the belt at both ends. Belt tension is provided by hand, I just pulled it tight with one hand and tightened the block with the other. Haven’t had any issues with sag or loosening yet.