I’m doing a bit of an upgrade in my shop and I found the LR4 to be pretty well suited for my needs as a hobbyist.

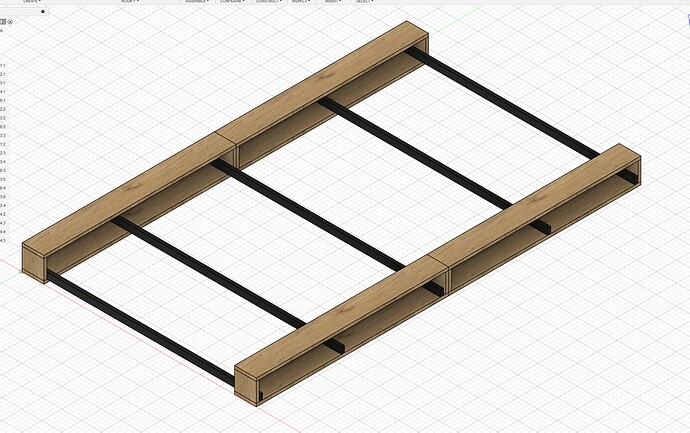

What I need advice on is the table build. I see the onshape file but I wanted to build it a bit differently. I am going to be using a drop table style for it, so I can flatten slabs. The idea is I’m going to build two parallel rails with extrusions between them for a nice flat surface.

What I am having issues with is finding how wide the “working” area has to be and with the rail widths (less of an issue because I plan to have them be 3-5" to better support the extrusions). Since it should have a working height of 4", throwing a scrap piece on the extrusions will give it room to work at it’s lowest point to cut any sheets and allow me to flatten thick slabs.

The Onshape file has the working piece off to a side with extra room on both sides and a lot of extra room on one side. Should I just assume that it was not aligned/centered? I can use that as a reference if so, around 52 1/4" for a full 48" working surface.

The image is a quick mockup of what I am going for on the table. The top of the extrusion to the rails would be the 4". I would be adding supports within them. The only thing I’m not sure I want to do is adding cross supports between the extrusions because I’ll be bolting them to the supports of the rails which should keep everything square and rigid. This will also the sitting under my outfeed for the table saw. So legs on the outside with a frame under this to support it.