that would be amazing if you could! my lowrider2 plasma table is getting painted today! and then its mostly just wiring left!! 163197669_1137200300129698_7928165740998501592_n|666x500

Nice work!

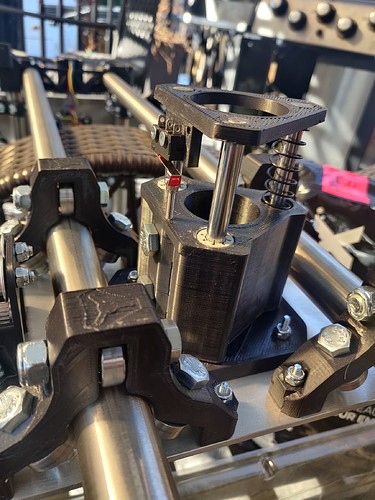

Here’s the stl files for the torch holder. TorchHolder.zip (176.2 KB)

What length rod did you use? I have everything ready to go and went with igus bushings for the 8mm rod. I ended up Raptor lining my table.

3 each of 8mm diameter x 100mm long linear rail shaft rods

6 each of LM8UU 8mm linear ball bearings

1 to 2 each of hex nuts with set screws (I don’t remember the size, 3/16" or 1/4" maybe)

1 to 3 each of springs that’ll fit over the rods.

I ordered the rods and bearings off banggood and got the jumbo set screw and spring at ace. I only used 1 spring and 1 set screw. I took the whole assembly with me to the ace hardware store and rummaged through the spring bin to find the right spring for the job. It doesn’t take much spring.

What’s raptor lining? Sounds fast!

Cool thanks, I got that all assembled now and installed. I have moved onto wiring now. Going with UCCNC, THC, Ohmic sensor, crash sensor, x and y squaring should be fun! Raptor lining is a 2 part coating that’s insanely strong and durable

!How does the crash sensor work?

From what I understand ill be using the Ohmic sensor on the end of the hypertherm CNC torch for doing initial touch off and the limit switch on your torch holder for crash detection so if the torch head gets bumped up the controller will get the signal. Im hoping I can auto square the Z axis by having it square on the top of the axis.

Oh okay. I usually see some kind of magnetic mount and a break away switch. A downside to what you describe is if a tip up catches the side of the torch lateral pressure won’t slide it up to activate that switch. I’m thinking it will only reliably detect crashes in the z direction.

I was hoping at least with the conical shape of the shield it would provide the vertical force for a trigger. the mount moves verryyy smooth.

Only one way to find out! Lemme know when you get it burning metal!

Trevor can I ask how big your compressor is?

I was going to buy a plasma yesterday in hopes of CNC’ing it, but I am seeing people recommend 30-60 gallon, favoring 60 gallon, 6CFM@90psi. That is a large loud expensive compressor. I guess since with CNC we are really pushing the duty cycle of both the plasma and the compressor.

I was kind of wondering if thinner material uses less air so like a 20gal 5cfm@90psi would work. That brings it down to “portable” and quiet.

Trevor?

The compressor I’m using is only a 30 gallon. 10.2 cfm @ 90 psi. I honestly haven’t given the compressor much thought. It’s what we already had so what we used. It runs just about constantly during a cut and is deafening but it is what it is.

I’ve got the compressor and plasma machine on two different 50amp circuits. The compressor doesn’t need 50 amps but that’s just how we wired up the shop.

Be sure to put some good air filtering in line before the plasma machine inlet.

For expert advice I’d recommend googling the key words “Jim Colt air compressor” and I’m sure you’ll learn more than you ever wanted to know quite quickly.

I’ve heard that really dry air is critical for plasma, so you may want to plan for a cooling loop, intercooler, or some other way of getting vapor out once the air has been compressed.

That too.

My plasma cutter has a built in filter but I’ve also picked up this filter/dryer as well: https://www.amazon.com/gp/product/B002PR8ZXK/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

I’ve seen some crazy copper cooling systems plumbed in that would make a moonshiner jealous but I haven’t tried anything beyond the linked filter.

I doubt I’ll ever get to running a plasma cutter in my basement shop, but I’ve got an airbrush I’d like to start playing with, and I’ve been intrigued by the idea of media blasting, which is another area where I understand that dry air is critical. I’ve got the cheapie Harbor Freight auto-drain on my (also cheapie) Harbor Freight 12 gallon compressor, and a basic water glass on the filter/regulator but am considering adding a desiccant stage or maybe a little oil cooler-style radiator between the compressor head and the tank.

Too many projects in the “some day” list.

Plasma’s are quite the rabbit hole. Jim colt has a good straight to the point style. Love it!

(Warning, don’t listen to me, no real CNC plasma experience yet). For thin sheets you can use “fine cut” consumables (if available for your cutter) that have smaller orifices, which should lead to less air used. How much less? I don’t know.

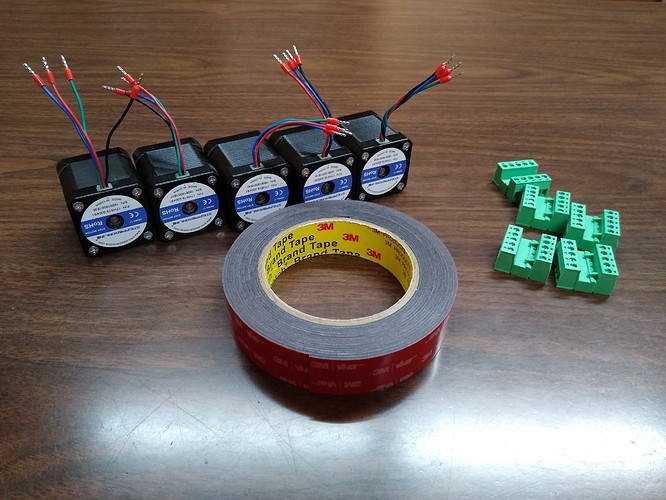

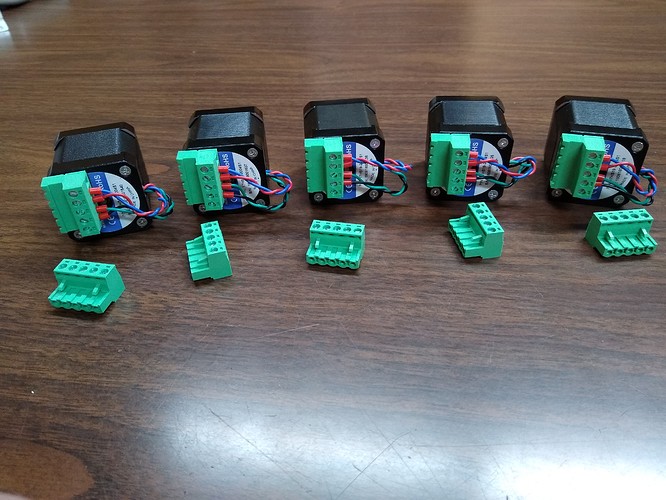

v1 purists wont like it but I’ve added screw terminal connectors to my steppers for part of an effort to tidy up my wiring.

Heresy!