So a lot has been going on with work, so havent had much time to get out to the Shed but I have achieved a bit.

The pingpong table has been reinforced with 3x2 ribs under the original MDF deck, with a12mm mdf spoil board added (and 12mm mdf wheel track added to make sure the sled still clears the spoil board even at lowest Z). The table is now approx 2mm out of flat, and while I have a surfacing bit, I haven’t had the time to improve on it - most of what I will do is through cuts anyway. 600mm x-y L-corner fence added at the origin, and milled square.

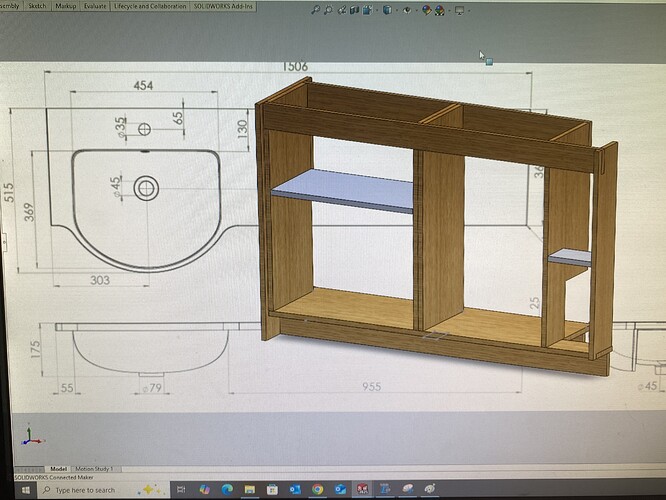

The pressing project for this build is a vanity unit for the bathroom I am renovating in the house. Nothing off the shelf fits, so I have designed my own ikea style unit, and will be using recycled Ikea Pax Wardobe sides as it’s hands down the cheapest way to get faced chipboard - light oak veneer in this case. Less than £20 for all I need for this, and probably enough to do the bath surround too!

(Sink, doors and toilet not modelled, but the end result will hopefully look like this)

In reality I would have had it built by now if I didn’t have the cnc, but I want to cnc it to say I have, and to prove a point to the other half about why I spend so much time in the shed! So the design calls for accuracy, and I thought I had better test the LR2 out, before jumping in!

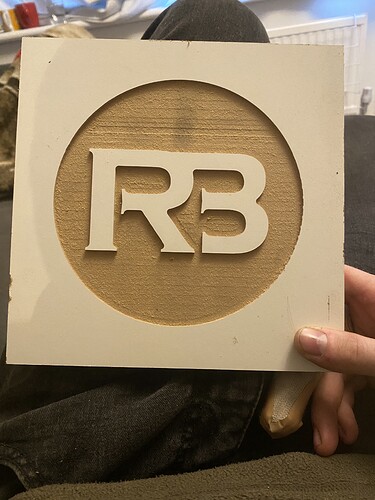

200mm square, parted with tabs. 2flute up upcut, 3.95mm dia

150mm pocketed circle. 2flute downcut, 3.9mm dia

Different bits as trying to learn about how they affect tear out of the facing. Looking at the the pocket though I think I haven’t got the step over set right as have wide lining

The square comes out 1.6mm (.8%) under in X, and 1.8mm (0.9%) under in Y

Circle comes out 0.5mm (.3%) under in x, 0.8mm (.5%) under in Y

Concerned that the deltas arent constant but I am also not sure I have the workflow right for the finishing pass?

But based on the above how should I move forward? Is this primarily a belt tension issue ? I know grub screws are first thing, but they are loctited to the moon and back so confident they are not the issue. Or do I need to adjust steps per mm? If so is there a step by step walkthrough for this?

Thanks as always for the help and advice! Really bitten by the bug now, just want to make sure I’m doing the machine justice!