Long time reader, and I bought @peeteebee ’s disassembled LR2 with great plans to get straight into a rebuild to get chips flying…. Then life got in the way!

I have too many projects on the go. House renovation, box truck conversion to horse transporter (with living accommodation), antique horse drawn carriage restoration, moped restoration to name a few…. Oh and of course a full time job and the aforementioned horse to care for. All this means that getting the low rider back together and working has taken a back seat.

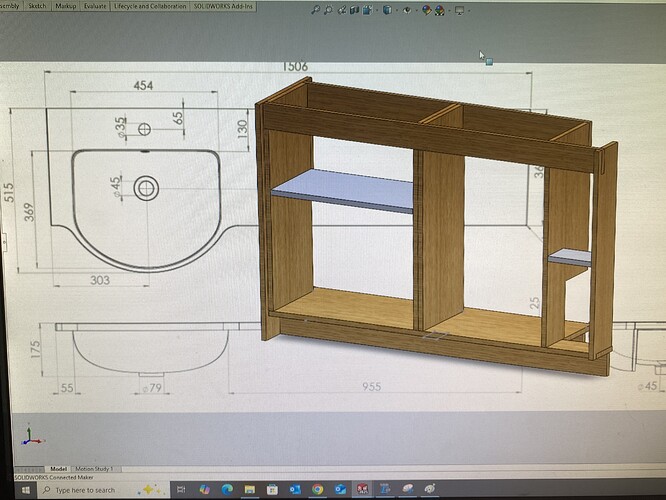

I also have a space problem, because the main projects I have in mind for the low rider will be require a full sheet bed (cabinet cutting, and sheet material cutting to make side skirts for the truck). In the UK most normal house only have a single garage, and mine is full with the carriage restoration, and a new bathroom (waiting for vanity cabinets!). I’m lucky to also have a 20’x8’ workshop in the garden, but that is also full to bursting.

Fully appreciate I am wayyy behind the curve here, but I have too many things on to build a lr4 so I’m working with what have and what I can hopefully get together and running quickly… at this stage it’s sheet particle board (old ikea wardrobes is cheap stock as they are faced, and no one wants to move them) and acm/dibond that I want to cut, so I thing the lr2 will do it just fine.

With all this in mind, the LR2 I have LR2 (disassembled), and having read a lot on here about tables (especially https://forum.v1e.com/t/table-ideas-for-those-just-getting-started/41036) Ive settled out on a using a folding ping pong / table tennis table as my basis. The reasons being.

- They come up cheap, because people don’t want to move them —> this is no issue for me.

- They fold up - see space constraints above. And if the lr2 is supported right it can live protected inside the files table.

- They are nearly fully sheet when open (9x5’)

- You can fold one half for smaller jobs.

- You could only have the lr2 on one half, then use the other half as an out feed table or for other projects

- The one I got is on wheels - which is wheely good when you need to move it.

So I bought one, similar to this

Metal frame, mdf table surface. Not 100%flat, quite warped across the width but can be braced if needed (I’m planning through cuts of sheet materials, so flatness isnt critical)

It barely fits in the shed, I can only open one side at a time, but the important thing is it fits!

So, I’m a the stage where I have 3 options as far as I see it:

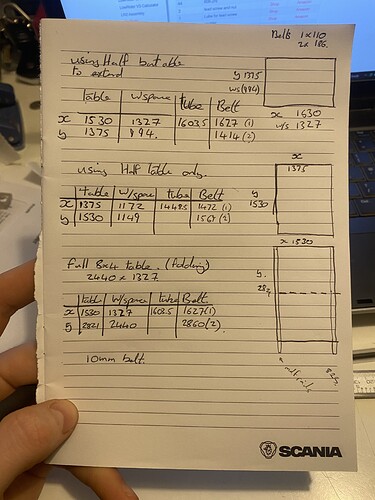

- Half table machine, x-axis 5ft table width, y axis 4.5ft table length, and use other side of the table for outfeed.

Pros:

Can build in situ, only use one half for a start. Then only use 2nd half when needed for outfeed table.

Only need to extend belts (or deal with long belts with excess length) to get to full sheet machine using 2nd half of table.

No issue with aligning table halves.

Can use other half table for other things when needed without disturbing cnc.

Cons:

X is greater than Y axis.

Not full sheet capable - need to use registery holes/dowels

Potentially waste half the table

- Use half the table, but have xaxis across the width:

Pros:

Y axis greater than x

Can build in situ, only use one half.

No issue with aligning table halves.

Can use other half table for other things when needed without disturbing cnc.

Cons:

Not full sheet capable - need to use registery holes/dowels

No outfeed capability.

Potentially waste half the table

- Full 9x5 table machine, x-axis 5ft table width, y axis 9ft table length, nearly full sheet

Pros:

Full sheet

Can use most of table for other things when needed without disturbing cnc.

Cons:

X is greater than Y axis.

issue with aligning table halves.

Need more space! May have to be used outside, or wait until garage is clear (garage only 8’x17)

Would need extending to get to a full 8ft working length.

I used the LR2 table calculator backwards to get these workspace dimensions

(Would be a good option to be able to plug in a fixed table size, and the calculator work out what workspace you can have - @vicious1 what are your thoughts for lr4 people with fixed table dimensions?)

Given all the above, I’m leaning to option one for now, with the option to go to full sheet when space and project require it. The only thing that I am majorly concerned about though is the 5ft axis, especially as the tubes are 25mm galvanised conduit - so x-axis deformation over length may be a problem?

What do you guys think? I haven’t found a ping pong table build that covers this so would be interested to hear from anyone who has been down this route, or wider-x LR2’s.

As always, massive thanks to all who contribute to the forum, it’s an amazing space and somewhere I come to read and learn everyday as a wind-down. Thanks to you Ryan’s for creating the machines and the community that give us all such incredible opportunities to build and enjoy within our own homes!