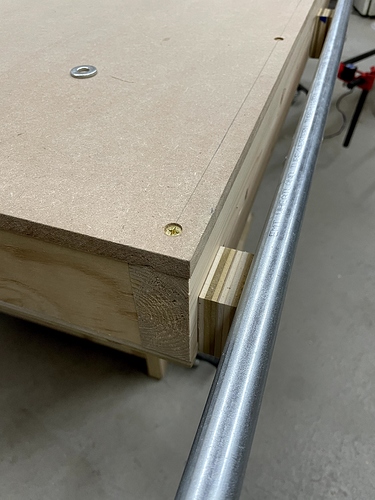

Finally finished my LR2 build after constantly getting sidetracked. Have a Shapeoko that’s worked well for me but often wish for more work area. Long ago I had access to a 4’x8’ ShopBot Alpha and really missed having that size, so this is a 4’x8’ torsion box design for the table with a replaceable 1/2” MDF top secured with endmill-friendlier brass screws. I had originally planned to use my Paulk workbench, but the 2 pieces were very awkward to get aligned perfectly with each other so I converted that to a miter/router station and used the wheeled base for the new table.

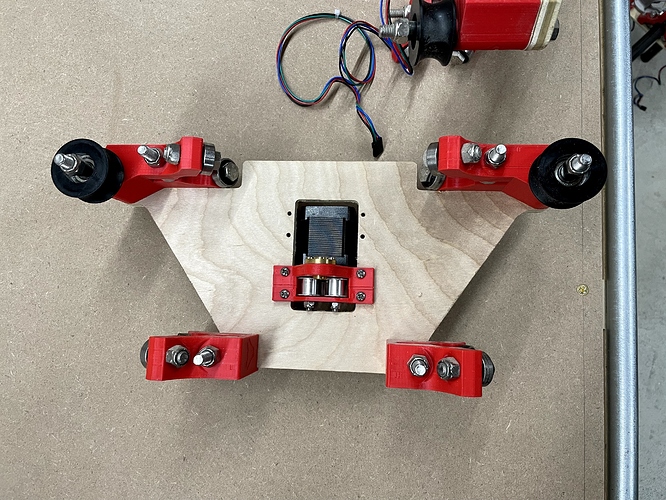

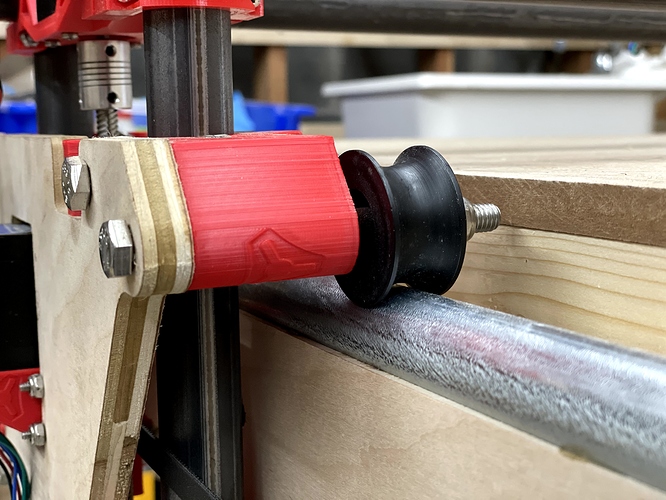

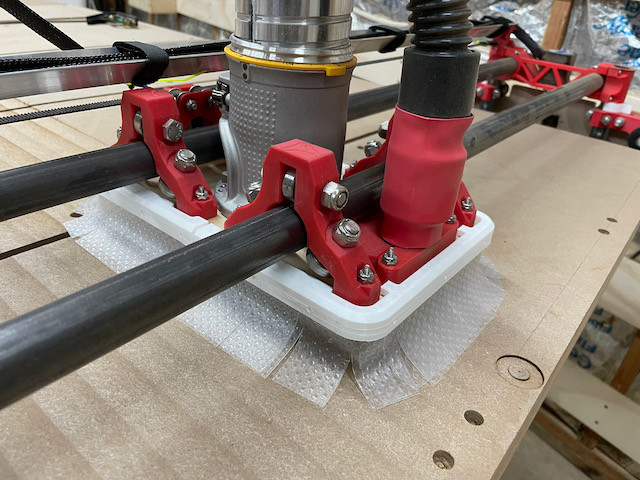

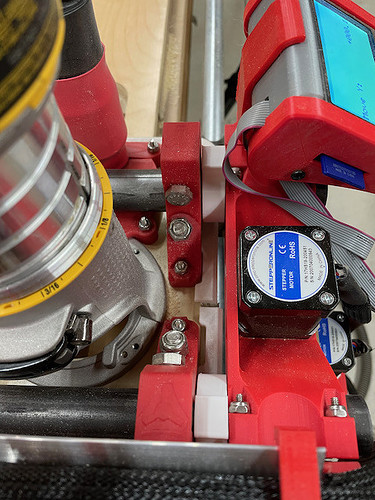

The interesting part was the long axis: I hacked together some linear rails out of EMT conduit and laminated ply. These rails are attached with spacers to the edge of the table to allow dust to fall off before reaching the rails and extends the cutting size on the short axis. I used U-groove pulley wheels instead of skate wheels. These ride on the conduit on the very edges of the pulleys and tracks on the tubes very nicely. Had to modify the Y plate and YZ rollers slightly to shift them downward since I wanted the rail below the surface of the table (so I could still use it as an assembly and table saw outfeed table). Also had to invert the long axis steppers and mount in the Y plate so that the belt could be mounted lower.

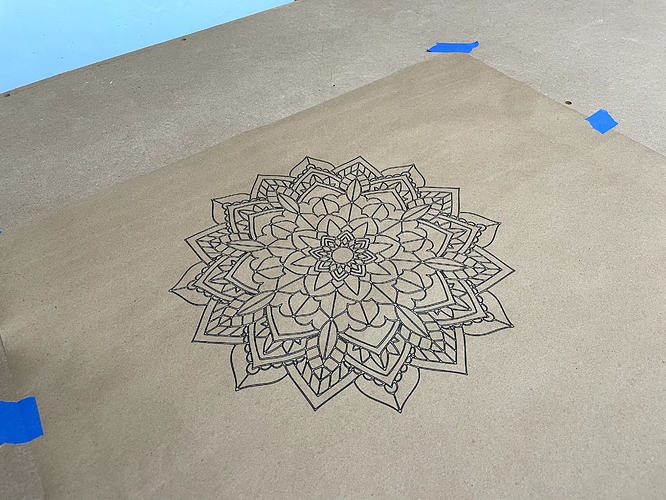

Got everything together and the crown printed with only minor hiccups. Then tested my normal toolchain with Cut2D and a bigger mandala design to put it through its paces. Size was spot-on and I thought it all turned out great! Having the whole machine on a wheeled base is nice so that you can pull it to the center of the room and have access to all 4 sides while running.

Mostly lurk here, but while I’m posting wanted to say a genuine thank you to all here: very good info and inspiring ideas and projects. Definitely want to try Rich’s aluminum extrusion XZ (“Upgrades on stiffness”) in the near future to see how that combined with the rails works out.