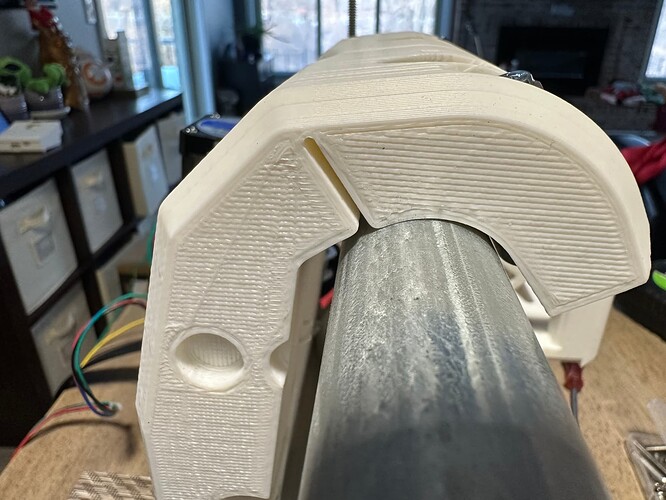

I am building a Lowrider V4 and am having some problems getting the core to move smoothly. The conduit is 1" EMT and measures 29.5 mm. I printed the brace_29p5.stl file so it should be a good match. Looking at how the bearings ride on the conduit, only the edge of the bearing is on the conduit. If I have the tension bolts loose enough for things to move somewhat smoothly, the top of the core hits the conduit. If I add enough tension to get the top of the core off the conduit, then it is too tight and the core won’t move. The bearings do spin freely and are 22mm. I did calibrate my 3D printer before printing everything so I am hoping that isn’t the issue.

I am not sure where to go from here. Hoping it is something simple. I am going to print another calibration print just to confirm the printer is ok. Any help would be greatly appreciated.