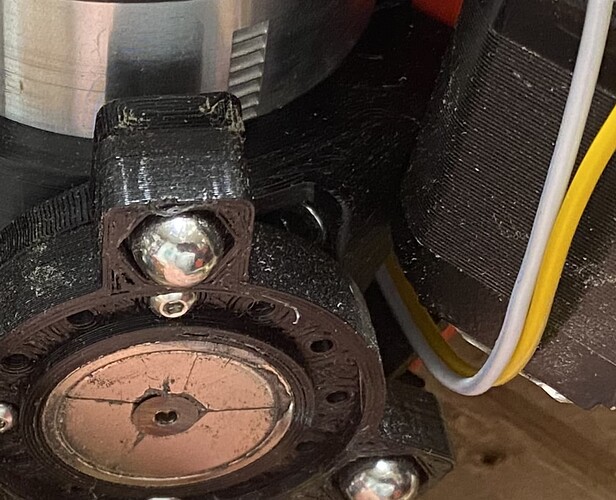

My initial prototype, which was much much larger, used M4 screws for the grooves that the spheres fit into, and it used the original tapered screws that came with the magnets. However, the whole thing was just too big. And using those tapered screws that came with the magnets meant that the parts had to be quite thick. Are you cutting off the tips of the tapered screws?

I will monitor for any deforming over time. Also, please keep me in the loop on whether or not you’re getting enough coupling force by using the magnets with the metal washers on the opposing side.

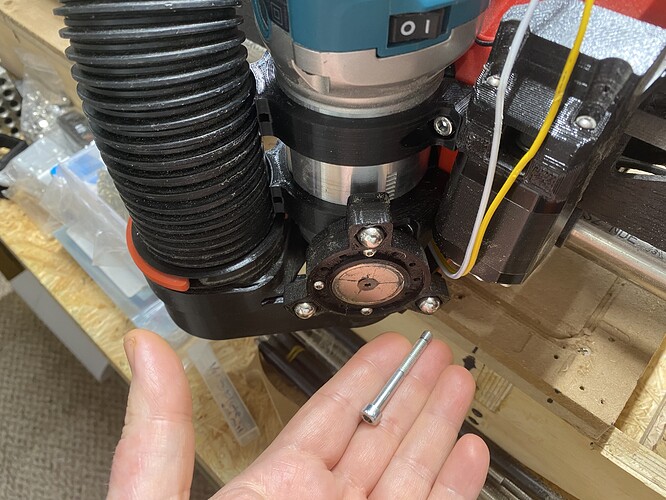

The screw for the magnet does poke out the back, and I would have to make a hole in the main mount, or drill a hole, or shorten the screw.

I wouldn’t worry too much about deforming the metal cap nuts or the screws. They should be hard enough, but plastic of the same size would almost certainly be mashed. I will also be keeping an eye on the plastic landing pads to see if they are getting smashed.

I’ll see about measuring the force with different depths. This one feels about right for a pen or light loads, but my hands are poor measurement devices and I don’t trust my intuition. I’ll make some drawings and that will at least be something.

No, it’s called design development, and it’s how a good idea turns into a great one!

What is everyone thoughts on using something like this to have a removable router / spindle?

You want the router as close to the Z as possible. Any distance away and the force on the gantry will be twisting, to the side, and not pushing up. So that’s the first reason not to have a quick change mount for a router.

The second is that you want this mount to be as rigid as possible. If you really want a square setup, you probably also need to have some shims to adjust the final alignment, and that has to be rigidly mounted. Any flex or slop in the mount will be bad for accuracy.

That said, if you are doing sign making or other art, precision and speed may not be as important as convenience. If you want to make that trade off, then this seems like a good choice. You will have to do new tests to make sure you have good cam settings. But as long as the router doesn’t fall off, it should cut.

I definitely don’t want it to fall off. That would be pretty dangerous.

One important distinction to remember here, is the difference between how both screws and magnets act as force multipliers when used in an array. Consider: one or two screws would not be enough to hold a router, but four are enough. That’s what is used. But the force required to remove any one of those screws, stays the same. By contrast, if multiple magnets were used to obtain more holding force in a giant version of this holder, removal of the holder becomes much much harder. With screws, they all work together when holding the tool, but they all work separately when you need to remove the holder. But with magnets, they all work together both in holding the tool and all work together against you trying to remove the tool. It’s totally possible to make one of these large enough, and with enough magnets, to hold a router, but then you’d have the issue that @jeffeb3 mentioned, of distance increasing likelihood of twisting, and the issue of not being able to remove it without major prying, which would add stress to the holder, potentially to the point of bending or breaking the holder.

I don’t want to think about the amount of time I’ve spent talking about drawings vs. illustrations. An unholy union of engineering and legal (another is patent and IP work, but I can avoid that mess).

I have made the above changes to my files for the project, but I don’t yet have the new version uploaded to Printables.

Before doing this project, I had not paid close enough attention to the topic to know that Stainless Steel May or May Not be Magnetic — I had tried first thing, right off the bat, to use a stainless steel fender washer instead of a magnet on the Mobile Base side, and was baffled that the washer would not stick to the magnet. Later, after I had already gone ahead with using magnets on the Mobile side, I finally found out my stainless steel washers were “austenitic” and not susceptible to magnetism.

I went ahead and published (same printables link) all the associated models including hex-mobile-base, multi-pen-holder, and a new extra-flexible pen holder:

This one uses 0.8 mm walls (2 extrusions at 0.4 each) with perforations to make it extra flexible. For felt pens I wanted a very gentle downforce without having to be super precise on Z.

I’ve included nut holders on all of these to make it easier to attach with the m3 screws. I would recommend adding these to your models since without them it’s a bit annoying to have to hold the nut so it doesn’t spin. With a pocket for the nut, it’s a non-issue.

Will do!

Newly released, a new, improved version 4.1 of the pen holder:

LowRider 3 CNC - Add-on - KINEMATIC Pen Holder - designed for LR3 Dust Shoe (v4.1)

Download: https://www.printables.com/model/484869-lowrider-3-cnc-add-on-kinematic-pen-holder-designe

Description from the Printables listing:

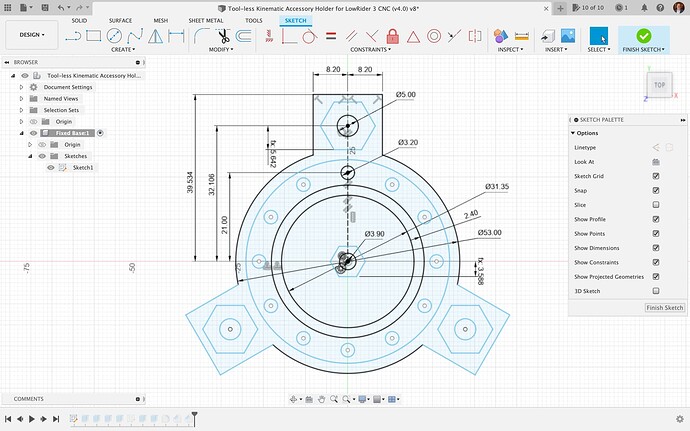

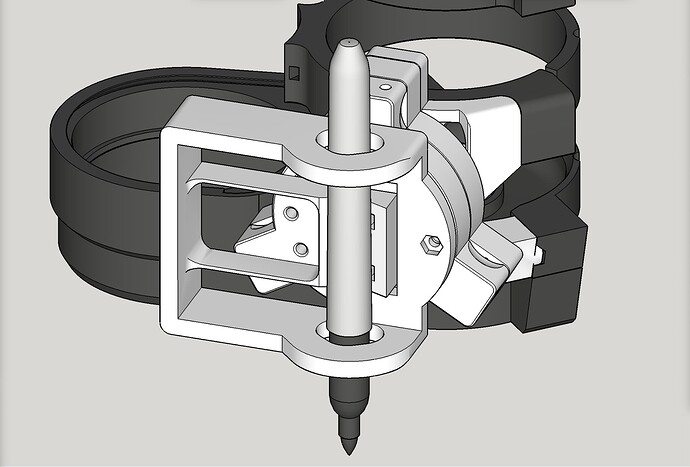

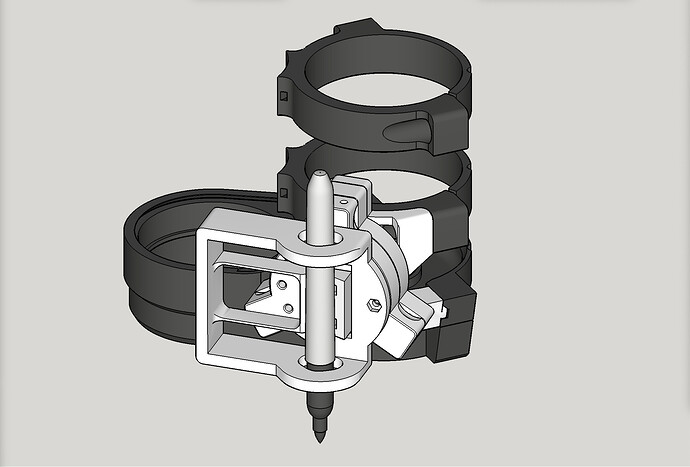

This is made to go with the LowRider v3 CNC - KINEMATIC Tool-less Quick-Change Accessory Holder - supports laser, drag knife, pen, etc (v4.0).

NOTE: June 8, 2023 — improved new release, v4.1, accomplishes two goals:

- The pen is located closer to the center point of the LR3’s router (less offset from the cutting bit)

- The offset distance is equal in both X and Y axes: ~52.043 mm for each. That’s from the center of the router bit to the edge of the mount where the side of the pen rests. To calculate your actual offset, be sure to add on the radius of your pen body. See example below. (For anyone curious, the 45-degree diagonal measure of offset from router bit center to the edge of the holder where the pen body rests, is ~73.6mm.) Having X and Y offsets be equal hopefully makes it a bit easier to handle coordination between drawing and cutting in the same project.

IMPORTANT ASSEMBLY TIP:

- Insert your two zip ties through the pen holder, before attaching the pen holder to the Mobile Base from the linked other listing!

Diagrams showing the X & Y offsets, and an illustration of calculating offset with a common Sharpie marker:

Here’s a helpful video I made about this (the video shows older v4.0):

OTHER COMPATIBLE TOOL HOLDERS INCLUDE:

- Laser mount for NEJE A40640 Diode Laser: Printables

- Pen Holder, not inverted, v4.0 - generic design for pens on LR3 Dust Shoe, made for this v4.0 kinematic system: Printables

- Drag Knife Holder v4.0 - 1.0mm spring leaf (for drag knife such as sold by V1 Engineering): Printables

Print, attach to the Mobile Base in the listing above, using three (3) screws and nuts, M3 x 16mm.

Install a pen using zip ties. Attach this and its Mobile Base to the Fixed Base on the LowRider v3, and draw something. Post results in the comments here.

Change log:

- June 8, 2023 — improved new release, v4.1. See above.

- May 18, 2023 — initial release, labelled v4.0 (because so many previous mixes).

My PayPal tip jar: https://paypal.me/design8studio

Various LowRider 3 CNC remixes:

View all my models and remixes on Printables:

*Amazon product links are affiliate links.

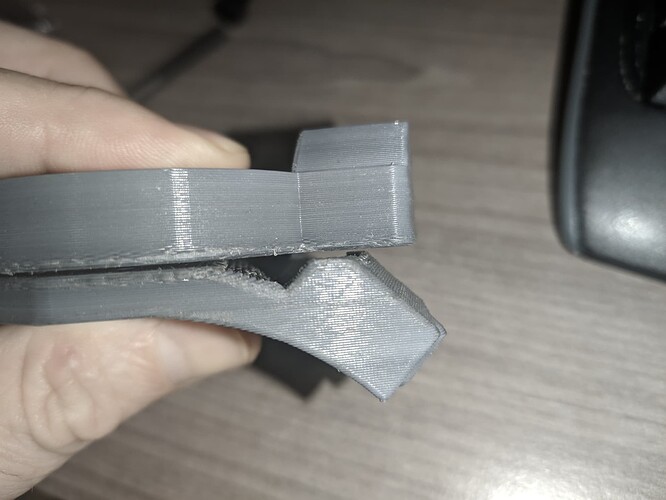

These combined models are looking pretty good. They printed well on my stock Ender 3. I do realize that I didn’t pay attention to print orientation and for the most part it didn’t appear to matter (Yet).

As I went to assemble, I realized that my M5 screws protrude through the plane of the Base for the bottom LR3 mount. Are you using button head or hex cap screws? Most of my metric collection is hex cap, and it LOOKS like it should have fit. However, I did also print this in a different orientation, so perhaps that makes a difference? I’m still learning the ins and outs of orientation for 3D printing.

Several short notes, and also some pics that will hopefully help.

I try to always upload my designs in the orientation intended for printing. I did so with this design.

The image below shows the M5 screws that I used, and shows a set of digital calipers measuring how wide its head is.

On my install that screw head fits down inside that printed well. My design has no part of the screw cap/head exposed outside of the main base part.

It looks like either your screws have a bigger head, or perhaps over-extrusion during printing made the well hole for the screw head too small for the head to fit.

Just to reiterate these are M5 x 45 mm.

This is not to say there might not be some other orientation that can work. Just to say that the provided orientation is known to work.

My screws are 8.44mm wide and 5.22mm tall. IT does fit horizontally in the well, but it might be a vertical size issue. Additionally I printed it with the well hole facing down, meaning that it was printing on supports and might have sagged. I’ll bet it is the combination of the two that make the tolerances just a bit too tight.

You have drawn attention to a potential issue I may have not taken into account. The top well is shown in photo as not an issue, but now I’m pondering the bottom well.

PS: the well opening (in the 3D modeling software) measures as just shy of 10.6 mm (10.598399 mm) in diameter.

More soon.

Yes, the top well worked fine for me, it was the bottom well that caused my issue. The top of the cap needs to be below the plane, all the way out to the edge, as that is where one of the three arms overlays.

I figured that I’d try drilling it out to see what would make it fit, and it’s not just filament sag. I had to get into the infill (I printed with 4 walls because it was a quick job and I left my previous settings.)

I can attach more photos if it would help.