So my LRV3 and 3 of the mpcncs i previously had all did this but lets speak of the LRV3. Basically after I power it on, if i raise the z it will fall back down on its own immediately as if the motors are not locked on like some units do. Now this may be due to something stupid on my end or maybe how it is supposed to be not sure. It is an exact V1 spec build on a 4x8 sheet including electronics minus using a bauer router (it matched). I only used it for the first time a few weeks ago but this winter would like to use it more often. In fact I have never even tried to home it lol. I simply dropped in an sd with a gcode file, manually leveed it, positioned then I hold the z motor while starting the router and hit print. I know there are things i didnt do but maybe some voices can help prior to the next start. Thanks in advance

Is this by chance a SKR Pro v1.2 board that you are using?

If so, what is probably happening is that the Z stub on one side is hitting the top of the YZ plate. That can happen during homing if the end stop switch on that side isn’t propely adjusted. It can also happen during homing due to a well documented issue where the limit switch doesn’t actually trigger when activated.

The Z stub can also hit the tip of the YZ plate if you do a manual move too far for the physical limits of the machine. For example, if you mistakenly try top do a 100mm Z+ move instead of a 10mm Z+ move, there is only 80mm or less that the machine can actually move before hitting the top of the YZ plate.

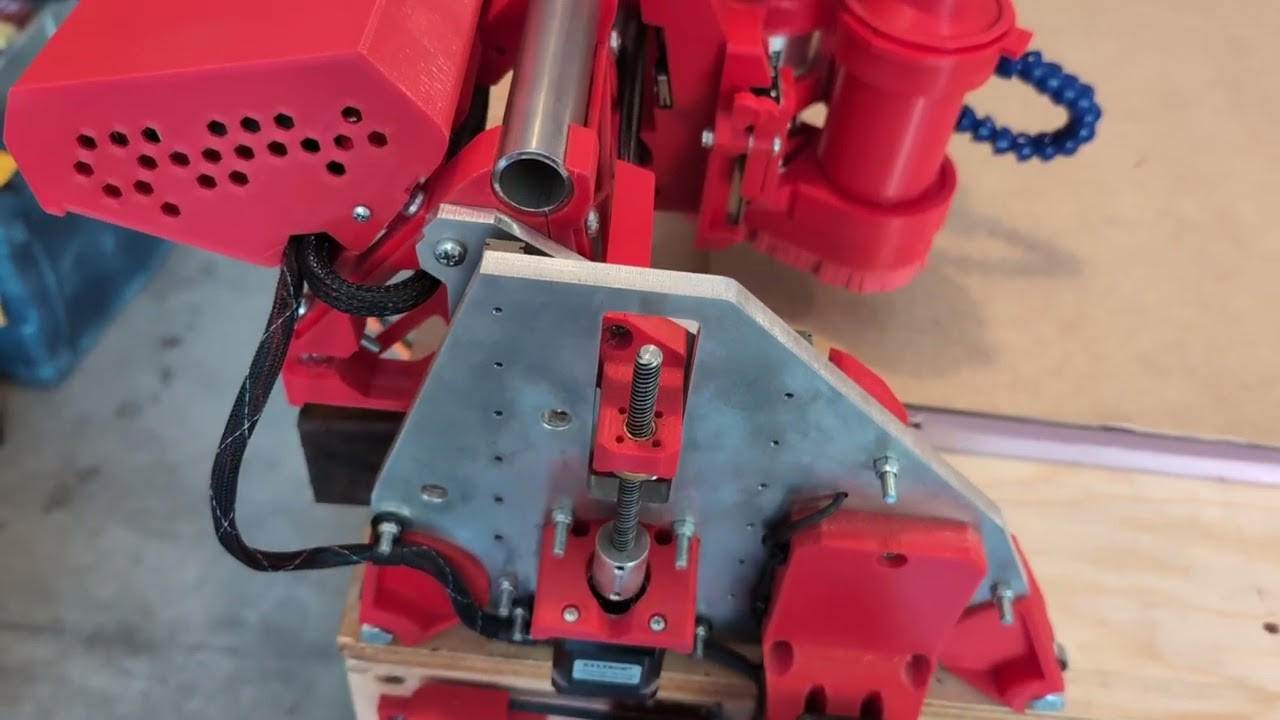

I had a similar issue that I took a video of:

IMO, you should always home all three axis prior to a job, then probe the Z and set Z=x (where x = the thickness of your probe). This tells the machine exactly where it is in relation to the stock.

i believe so but i havent even got to the point of moving any axis electronically. i literally power up, looks like its on a slope, turn it off to adjust it closer to what it should be, turn it on and it fall. Not starting from the top. I am feeling like it is how it wore the firmware maybe?

Ok, that may or may not indicate a problem. We need to verify if the motors are working properly.

When you turn it on, do you try to move any of the motors while it is powered on, either electrically (through a move or home command), or manually (by turning the lead screws by hand)?? What happens when you do that?

Do the motors work at all? Once you move them electrically a little bit and then stop, they should have a “holding current” that keeps them in position (the lead screws won’t turn easily by hand). Is this happening?

When you start it up and it is “on a slope”, and then you turn it off again, do you turn the lead screws to raise one side, or to lower the other side? You might try putting a wooden block under each side of the gantry to hold it up during power off, and to keep them even until you home the Z axis.

Maybe post a video of what is happening so that we can see what is going on.

This is a good troubleshooting step. If the axis that drops is freely able to turn when the machine is powered but the other side is much more difficult, then it likely means the motor that freely turns is not getting powered properly. Could be bad wiring, or a bad stepper driver on your controller.

Which controller are you using for your build?

Okay I finally got a chance to get the machine back out and working now that my other projects are done. I’m working on building a wine rack and I realized that only one of the z stepper motors drop it doesn’t do it after I have digitally moved it via the touch screen. Also the home function does not work at all correctly in fact the x-axis goes the wrong way away from the limit switch whatever that means.