Sorry - I was just deleting my replies, as I saw that you did say acetone up there… it’s a LONG thread!

no problem…

and yes - that’s what I was referring to. I also thought the “Reply” would put a little sub-reply… I might be doing something wrong…

Just scanned over this thread and gotta say I am happy to see some fellow rc’ers here! I have been doing RC planes for erm… like 36years now (I have an appreciably sized fleet ranging from 60 nitros to indoor 3D foamies… all kinds of fast stuff too). I have built many foamies myself over the past decade, but kinda fell out of it after getting into pylon racers and drones. Now with an mpcnc of course I have had some thoughts about old designs I played with. Mostly balsa laser ideas, also considered foam but was not enchanted by the idea of cutting with a router. This needle cutter idea looks neat and simple… vs the Hotwire methods I have imagined. This might be the thing that gets me back into design/build/fly. Thanks for sharing!

One of my initial drivers of size for the MPCNC was to hold full sheets of dollar-store foam core so as to try out some of the Flite Test free designs.

I still have about 20’ of the old BluCor FFF foam to use up… plus 2 boxes of depron and epp, mixed thicknesses. I imagine epp won’t cut well with the needle, unfortunately. That may need some form of hotwire, or reciprocating razor of some sort.

I’m pretty much retired from the RC thing nowadays… I lost my fishing/flying buddy several years ago and, at nearly 75 years, I don’t have the heart, energy, and/or motivation to continue on my own.

If the needle-cutter looks interesting to you, you can read/watch its “out in the open” evolution and development over the past 5+ years in my lengthy FliteTest forum thread, “Cutting foam sheets… with a needle!”

I had actually started needle-cutter development 5-6 years before that but had started building and using MPCNC as my CNC “vehicle of choice” at the beginning of the FT thread. It’s long, eclectic, and not exactly light reading but there is tons of good information and, being chronological, the most current information is the later stuff in the thread.

– David

There’s hardly any sheet foam in use by RC’ers that hasn’t been successfully cut with the needle cutter.

Here’s a post from one of our German friends in the FT thread who needle-cut, built, and flew light-weight (indoor?) planes built with 3mm EPP… he swore by it ![]()

– David

As my friends always say… that looks good enough for the girls we date! Thanks for the link. I will be studying up on this to get a tattoo rig on my mpcnc.

another ex-RCer here…started with RTP and ended with 1/4 scale 50cc. Stopped a couple of years ago as I stopped enjoying the days out at the field. For a foam quickie I can highly recommend one of these made out of 6mm Depron…that will cut well with a needle

Excellent hi-alpha, dead slow low passes and tail down landings…

Plans available -here

Ah! A blast from the past! My buddy and I needle-cut, built, flew – and crashed – a bunch of dekan’s F22 foamies… and had a ton of fun doing it. With the needle-cutter, we could cut a new plane, transfer the electrics from the crashed plane to the new, and be back in the air in just a few hours. It also inspired a whole fleet of other planes…

– David

This one looks a bit tricky to put together…

“You have to listen to the notes she didn’t play”

“Oh man, I could have done that at home”

Yeah… negative pieces can be handy when doing the CAD but are a bear to assemble. That photo was for all the “hand-cutters” and skeptics out there… there weren’t many needle-cutters in existence then

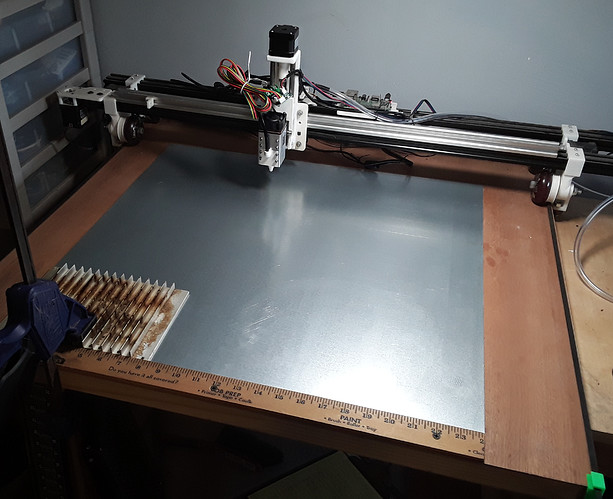

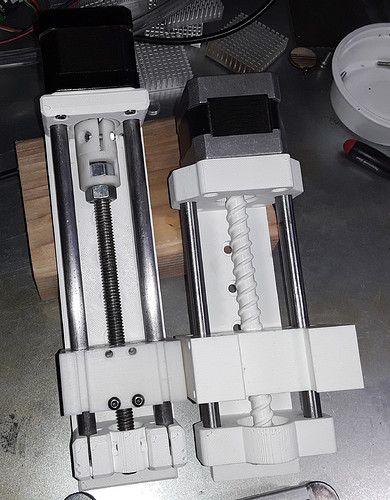

With the recent interest in Neje’s new dual-diode A40640 laser module, my poor Foam Ripper’s Z-axis has once again undergone more development. I had apparently skipped documenting the move from the last iteration of the little BB-bearing linear slides to a stronger version using threaded rod and Nema17 motor drive…

but I didn’t like the tall profile and occasional coupler issue. So I decided to combine a couple of ideas using the printed leadscrew of the BB-bearing models and Nema17 motor drive.

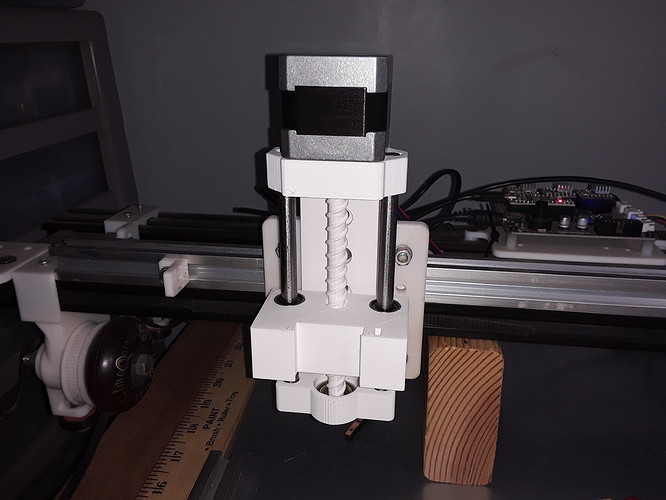

Shorter yet, without the coupler, and about the same ~75mm travel, I’ve come up with a simpler Z-axis that consists of only 3 printed parts…

The Nema17 motor shaft is fully inserted into a D-shaped recess up the center of the printed leadscrew, effectively creating an intergrated motor/leadscrew and doing away with the coupler. Skate bearings capture both ends of the leadscrew…

There is a touch of slop/sag in the carriage due to using LM8UU linear bearings on 5/16" drill rod but replacing the rails with proper 8mm polished rod should help.

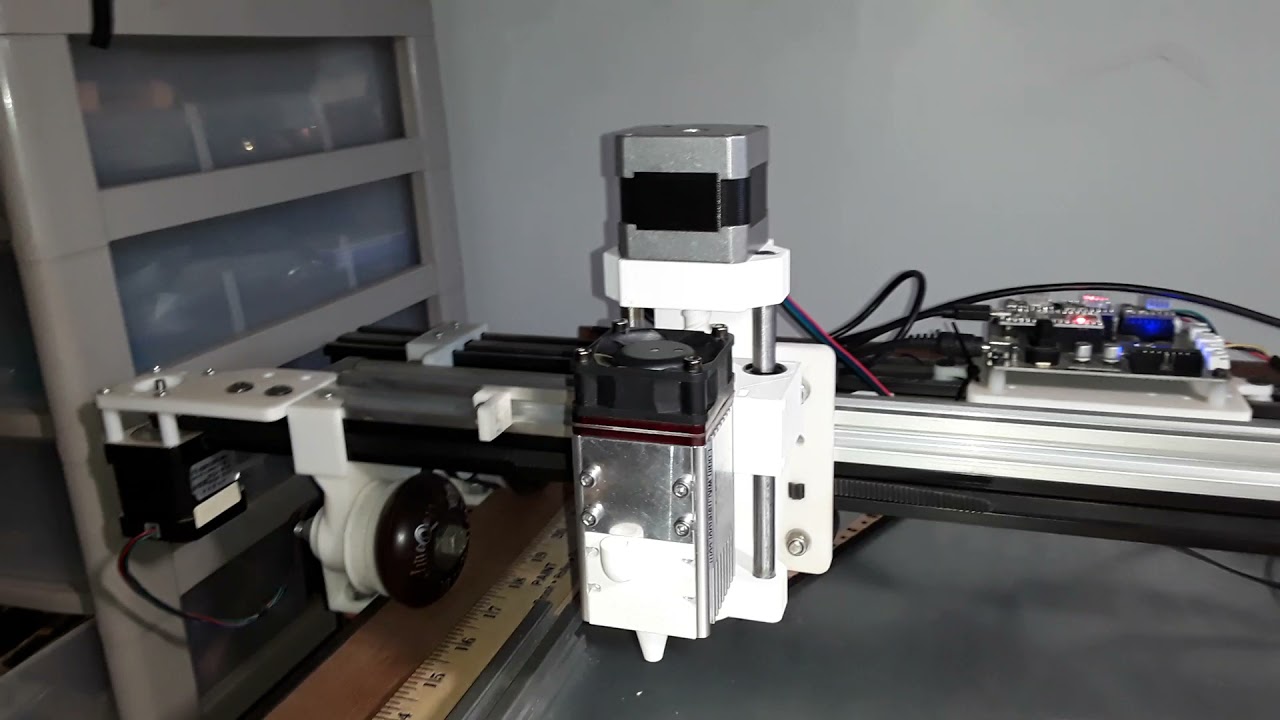

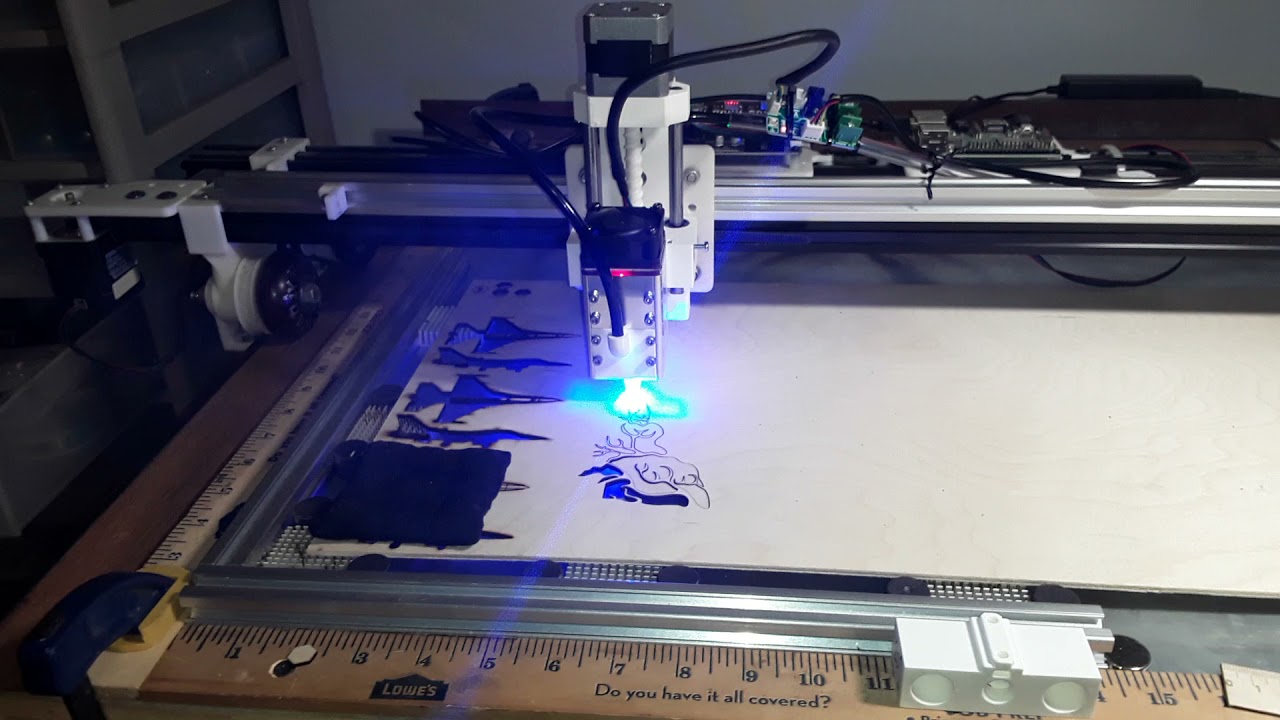

In action, with Neje A40640 ~15W laser cutting 3mm in one pass at 150mm/min and 100% power. Also sports my recently developed printed air-assist…

I’ve published this Z-axis design to Thingiverse, as well as the air-assist parts.

– David

3D printed Z-axis leadscrew?! We need a mind blown emoji!

That’s pretty awesome! Thanks for sharing!

I was also thinking about getting that dual-diode laser and this has pretty much sealed the deal!

I was curious about that Neje A40640 laser module someone had mentioned here, so bought one to test and hopefully install on a laser engraver I’d built for my daughter. TBH I wasn’t really expecting much but was shocked to see the vastly improved beam geometry… with line/spot definition on par with my 2.5W lasers but far more power. Daughter agreed and seems very happy now being able to cut much faster and thicker materials for her wooden jewelry. I was impressed enough to order a 2nd one for myself… the one shown cutting 3mm ply above.

![]()

![]()

You’re convincing me, David. I see the 15W (40W) version on amazon for about $315. I am assuming that is a bloated price for the convenience of 2 day shipping. Where did you get yours?

I bought mine directly from the Neje shop for $259 and free shipping, Jeff. They have a US warehouse and I received both my units within 4 days of order IIRC. Hassle-free and quick… no issues performance or quality. I’m a happy camper!

The us shop is out of stock, and it is $239 from China. I am going to pull the trigger. I just need a day or two to think about it.