When last I left off I was astonished at what I was seeing… a skewed raster image. TBH from the beginning, I fully expected to have the put training wheels on the machine to keep it from running off the side of the road. What I didn’t expect was that it would gradually creep down the road in the same direction it was traveling.

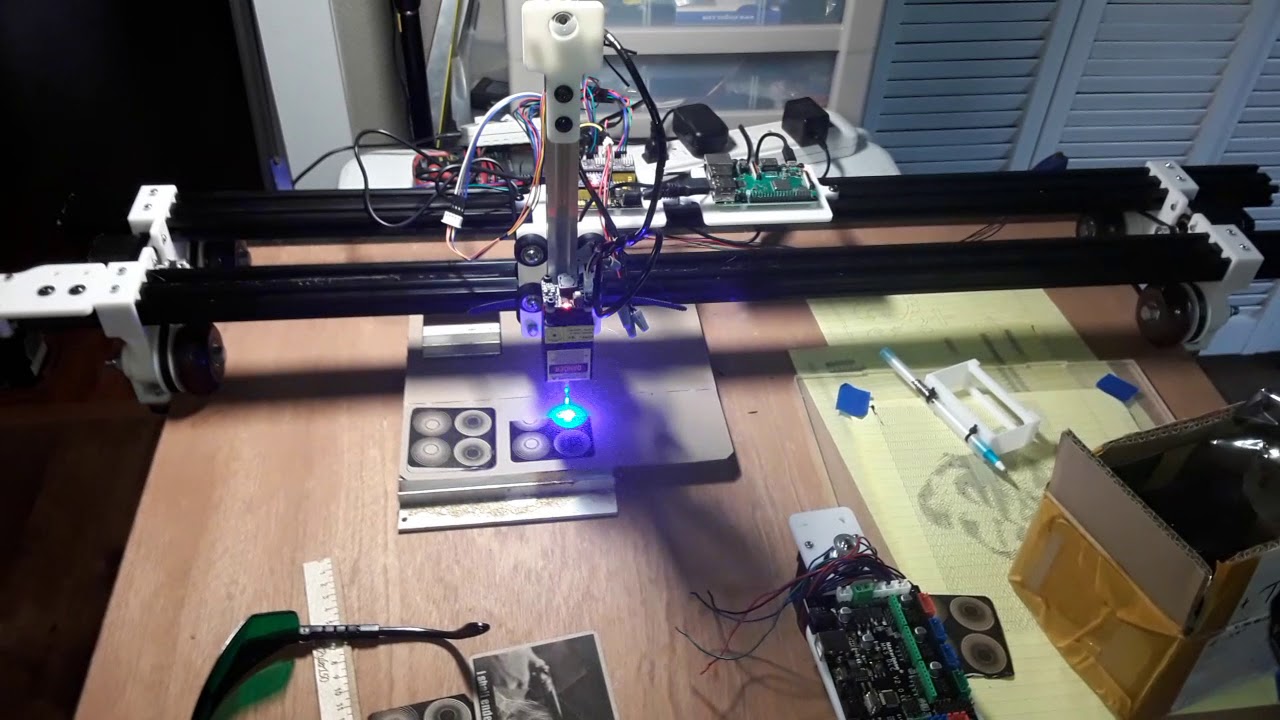

So, after pondering things half the night – microstepping, dpi, etc. – I started not-so-fresh this morning. I decided to use a smaller image and try again. This ran to conclusion, complete with the expected raster skew… and kinda surrounded by a perfectly square vector/profile cut! Whut tha… ???

So, I decided to try a vertically scanned image to see what I could see… and fully expected to see the image skew along the Y axis this time. But, surprisingly, I got a nice, square image out of it…

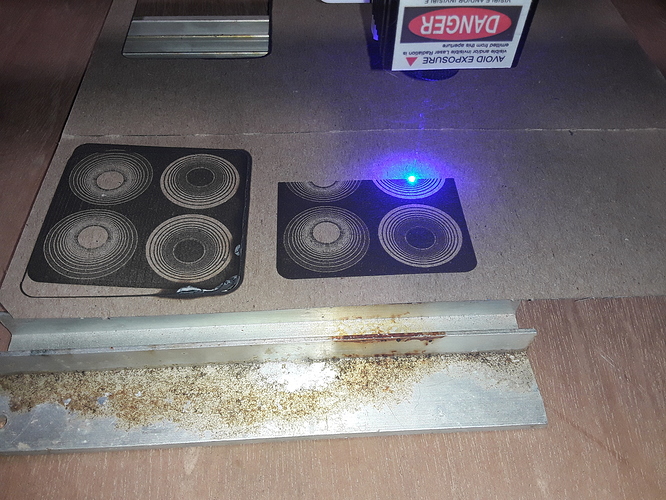

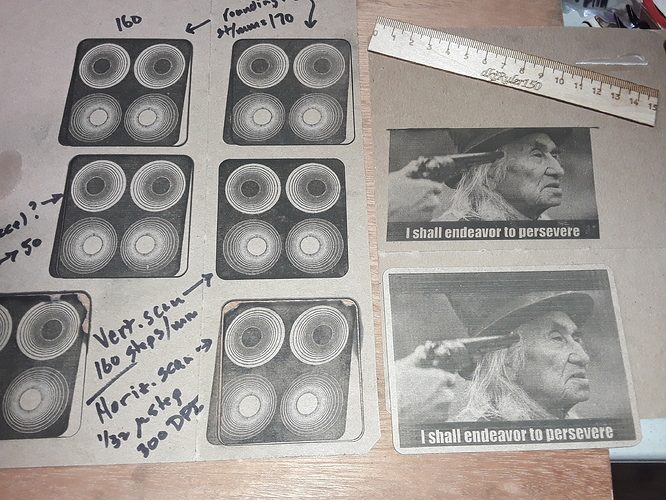

Of note, my X-axis is the direction the tractors roll… and where the skew takes place. Since these have printed 78-tooth pulleys affixed to the wheels, the steps/mm setting is pretty ugly – 169.473. In the Y-axis, things are cleaner… motor, pulley, idler, and GT2 belt… steps/mm is 160.000. Since vertical scanning made a dramatic difference, I then began to suspect “rounding errors”… with the poor, little Nano just unable to keep up. So then I rounded the NASTY-looking 169.473 to 170.000… and then 160.000… and I still get the skewed images (top two of the middle 5 images)…

It does appear there may be a little less slant to the top two images but it still ain’t right. So, grasping at straws, I began to wonder if it was possible I was “slipping the tires” a little and changed the X-axis acceleration from 100 to 50… the middle-left image appears virtually the same.

The easy way out, of course, is to simply sit at end of the table (or turn the machine 90*) and swap the X and Y axes. Given the short door cut-off serving as the work surface, it would look perfectly normal using it that way. There’d be less mass moving on horizontally-scanned images that way as well… though my FoamRipper doesn’t seem to have the issue, with an even bigger, heavier gantry, and did the Chief Dan George image I used for comparison.

So I’ll turn the machine 90* and swap the X and Y axes, temporarily. But I’m really at a loss as to why I’m seeing this now… and never before, in the some several laser machines I’ve built in the past???

Any ideas? Jeff? Jamie? All you other “brains” out there… not wrapped up in all the Primo hoopla? ![]()

And, yes… I did check all the grub screws ![]()

– David