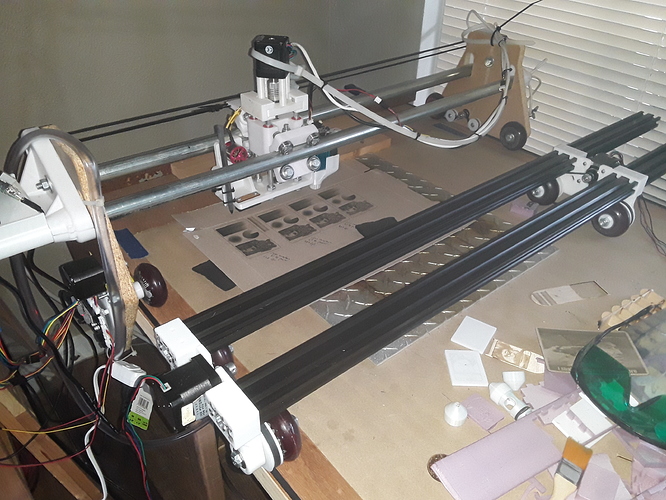

A FoamRipper upgrade!?!

Recently inspired by @geodave’s “Rolling Plotter” build, I couldn’t shake the feeling that this could be a really neat gantry for FoamRipper. I modified Dave’s wheel design to use the 60mm skate wheels used on LowRider and FoamRipper… and look forward to duplicating his plotter design – at least mechanically – going forward.

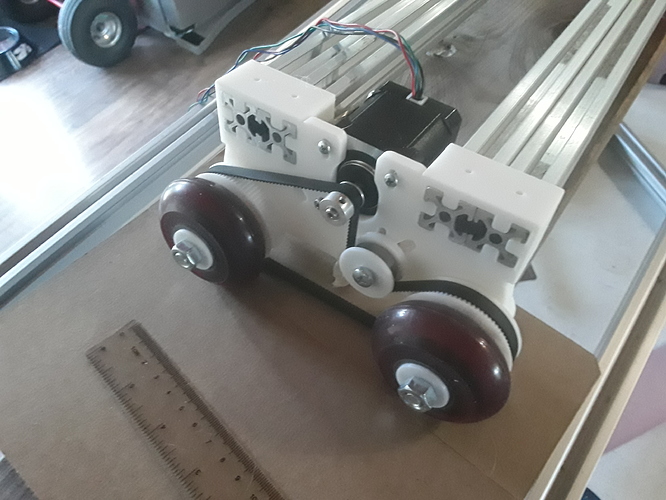

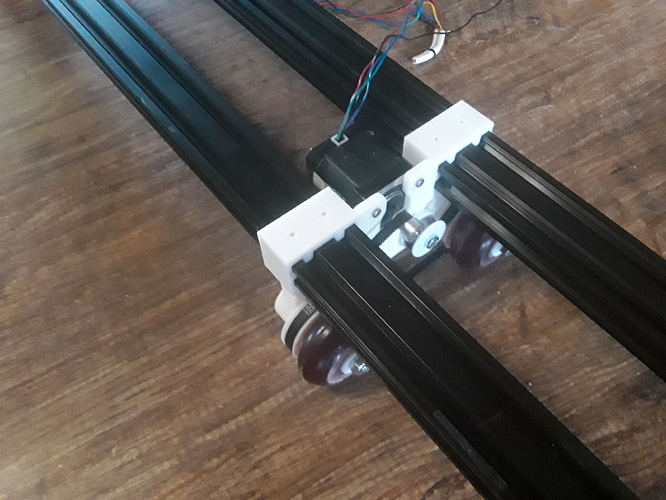

In this design the skate wheels, instead of free-wheeling, are driven. A printed 78(?) tooth wheel hub fits snugly where the inner bearing ordinarily goes and a simple filler hub replaces the outer bearing. A 444 mm closed-loop belt, an idler bearing, and a stepper motor and drive gear round out the drive mechanics mounted on the endplate…

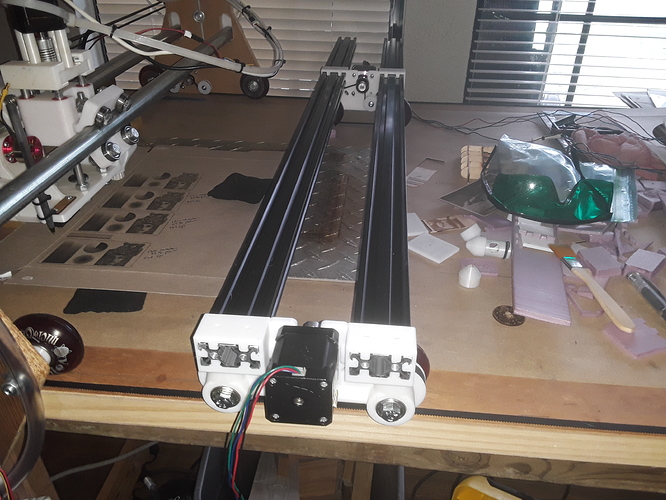

I also modified the extrusion to endplate connection to allow adjustable spacing/span between the drive wheel assemblies. It also allows for reversible endplate installation… wheels inside or wheels outside.

Though the rails are shown flush in this photo, I suspect any excess rail could hang over at this end to allow a small shelf to be affixed for the electronics and display… similar to the existing gantry.

Next up, I’ll try to get the motors wired up and move this axis… which will be the X-axis. I then hope to be able to use Dave’s motor and idler mounts and moving carriage/plate for the Y axis. Finally I’ll take a look at his Z-axis… I can’t remember off-hand whether he wound up using a stepper or servo. Once all axes are moving properly, plotter functionality will be the first order of business… and the obligatory crown. Then… probably laser.

Always fun, a new machine build. Later.

– David