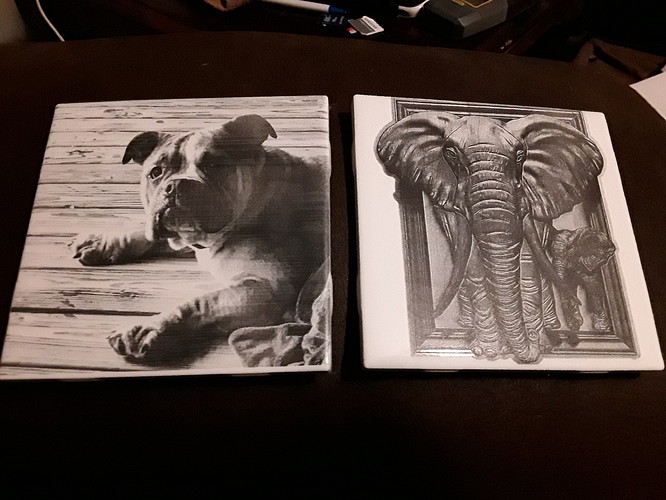

Kids got the new dog, so it seems expected that I do something about it…

Mentioned cleaning the lens last post and I think it really had a positive effect. I was able to up the speed and power back up to previous levels (1200 mm/min and 85%) and started getting far better results…

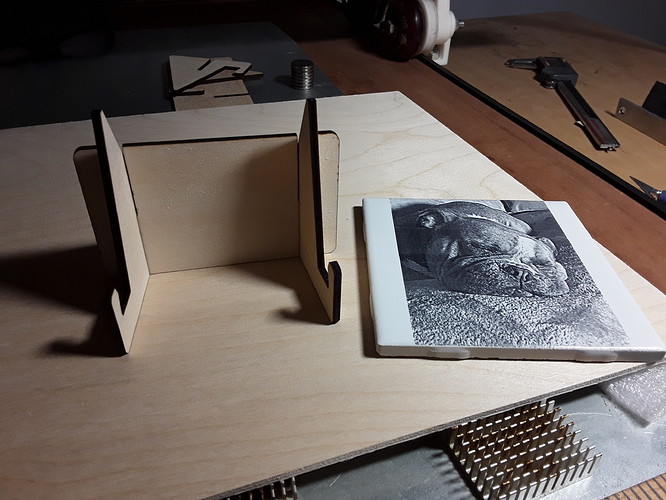

Daughter and I decided we need a small photo/tile stand… so cut one from 3mm plywood with the Neje A40640 laser module…

Finally, after a tough day (and following the dog’s example)… I took a nap.

– David