Ive build a lowrider cnc

But i have problems slicing my Files

If y make a File 100 x 100 mm a save it to SD car an put it on my machine it cuts it much more bigger

Im using kiri moto and vetric aspire

If you move 10mm on the lcd screen, does it move 10mm? Maybe you have the wrong steps per mm.

HI jeffeb3 no it dosent it moves 20mm

Where and how do i change the steps per mm

HI jeffeb3

Ive tested all axis and yes They move 20mm insted of 10mm

If you send M503, it will show you what steps/mm you have.

M92 X100 Y100 Z400 will change them to 100,100,400. You want to half whatever you’ve got.

M500 will save those steps/mm if that works.

If you only want to use the lcd, the settings are in there too, but it will take ages to change them in the screen.

My guess is you flashed the ramps firmware but have a4498 drivers. Is that right?

Im trying to conect it to a pc to use universal gcode sender im using a bigtreetech board v 1.4 with tmc2208 v3 uart

Im trying to conect it to a pc to use universal gcode sender im using a bigtreetech board v 1.4 with tmc2208 v3 uart

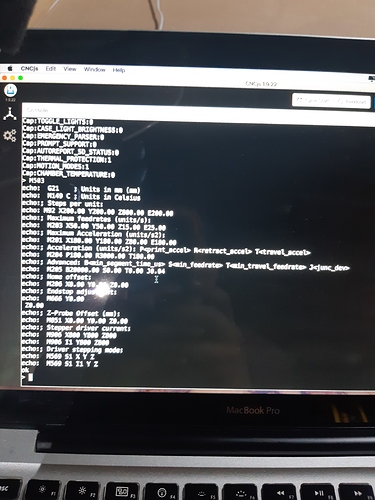

this is what it came UP on cncjs

That shows you have M92 X200 Y200 Z800.

Send this one line at a time:

M92 X100 Y100 Z100

M500

Then try jogging again and see if it is about 10mm for a 10mm move.

does move 10mm but y made a cube 10 x 8 cm but it cuts

10 x 8.5 cm

That is really far off.

Does it move 80mm when you command 80mm? Is anything loose enough to account for a 5mm swing? Are both ends energized and moving? I can’t imagine a low rider working with just one Y motor.

I have 611 as X and Y side plates Z is UP and down and have them with dual endstops