Is it okay to cut the strut plates in 2 pieces or does it need to be one full piece?

i want to make it out of 1/4 aluminum but I’m only getting 4ft x 1ft pieces

I don’t have an answer to your question at the moment, but might I suggest a bit more descriptive title for this thread?

It might draw in more eyes, as well as make it more easily searchable for others in the future

My gut tells me not to do it and rather use HDF and maybe a 1 or 2mm aluminium plate as a front if you want the look. ![]()

so, I was thinking about this the other day. What IF you print 2 braces, one on top of the other. That way it is ONE part, and you can join the 2 pieces there (or you could just put 2 braces together, maybe bolt them together).

what do you suggest I change it too?

HDF is like MDF but harder. ![]()

nice thanks i was only doing aluminum for the stability.

I’ve been using HDF on both the LR3 and 4 and it’s sufficient. ![]()

where you were joining would defeat putting it on. There would be no rigidity there.

You would need a splice of some sort. but like Philipp said, Hardboard is sufficient.

Heck mine is performing awesome and I have not even added it yet ![]()

Have you checked around for longer pieces? Metal Supermarket or another metal supplier should be able to provide longer sections. Maybe in a narrower width but longer (6" x 96’). Check their “drop” bin for cuts that may work for your needs.

Are you maybe thinking 2 layers of 1/8" thick MDF/Ply struts layered and glue bonded (Titebond III)?

e.g for Front…

Ideally want your final Strut to mechanically be a ‘single’ Strut to help rigidity, and help prevent belt from pulling YZ plates inwards.

Consider finding a way to make single piece struts, maybe start with Bootstrap mode, or temporarily building extra long Y until Struts are cut. Or cut at friend’s/MakerSpace if that’s an option.

I just can’t see doing them in 2 pieces being a good idea. But I honestly don’t know for sure. Thats above my pay grade lol

But I will say check with any local welding shops around your area. That’s where I get my aluminum from. Ask if they have any drops of 1/4” plate. Last time I got some I had to get a decent sized piece to have the length I needed. But I am covered on aluminum for anything that might come up for a long time lol

TIG welding them? But anyway, I think you can find narrow band much longer than that…. Maybe

No way they would be straight after that. Not near as straight as one solid piece. And any introduced skew will not be good. That is what has me worried about doing it in 2 pieces.

I am really curious of what @vicious1 thinks about them being done in multiple parts. I don’t recall it ever being talked about before.

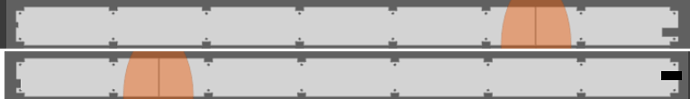

And overlapping them on one of the bolting point milling both ends at half of the thickness?

I’m willing to bet you would be more rigid with MDF the full length vs Aluminum pieced

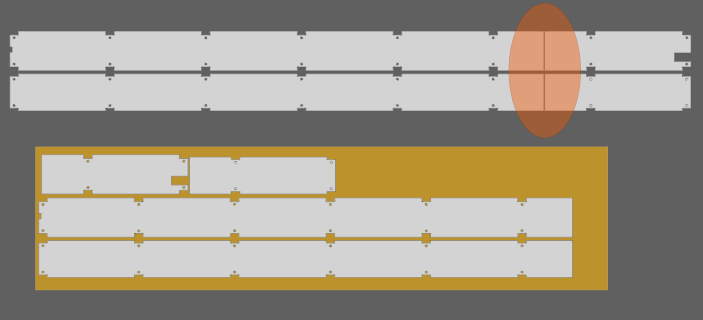

i was thinking to do it like this

thanks for all the feed back