I just put power to my new build and it went well. The Z axis was stalling and making a grinding noise. I’m using the jackpot controller. After a few tries I increased the motor current on both Z motors from 0.800a to 1.000a. This seems to have solved the problem. Is this setting okay?? If yes, how much can it be increased to if needed?

It shouldn’t be necessary.

You may need to do one or more of the following:

Lube your lead screws

Confirm correct motion of your XZ plates on the linear bearings

Check for misalignment of the Z stubs.

Something else is wrong, you don’t need to increase it at all if your machine is correctly assembled/lubed/adjusted.

Okay, I haven’t added any lubricant yet. It definitely could use it. I do think that will help

@Justus

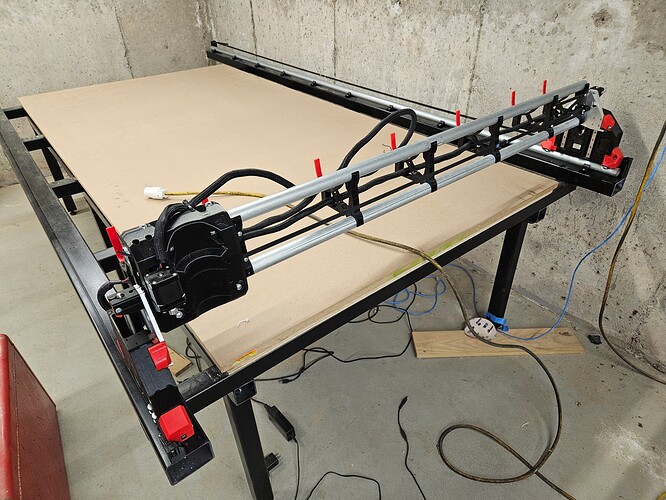

On a side note: sharp build!

Now THAT is a table!

Thank you Doug! Your table design is what inspired me to do this build. I’ll post some more when it’s operational.

It is impressive. Great job. I look forward to seeing more of how you did it.

This is amazing! Nice work!

And yes I had the same issue with my z0 and a little lube made the issue go completely away.

What is everyone using to lubricate their leadscrews? I used dielectric grease before (the same I use on my printer leadscrews) as well as FluidFilm, but wasn’t a fan of dust collecting in the “wet” lubricants. This time I used a dry PTFE lube on both leadscrews and linear rails to try and avoid dust build up, but curious what others would recommend?

Superlube.

Nice, that’s what I used before and still have a bunch left over. I’ll add a couple dabs here and there.

Yea, for my LR3, I used what came in the kit.

I’m going through my giant-ass bottle faster than I thought I would. Handy stuff!

Edit: “fast” being used for lr2, lr3, and now LR4. Thought I’d use it once then forget about it.

I’ve had mine for years… I know it’s food grade, but I think your other toys would work better with different lube… ![]()

![]()