Yes. But bear in mind, that command simply invokes an existing skew compensation profile already stored in your printer.cfg file. The spreadsheet gives a command that inserts those values into the config file. If you did that step, then “Machine start G-code” entry should work.

Yup did that step. Ok, well we’ll see how she turns out in the morning. Thanks for the assist!! Tomorrow night I should be printing parts!!

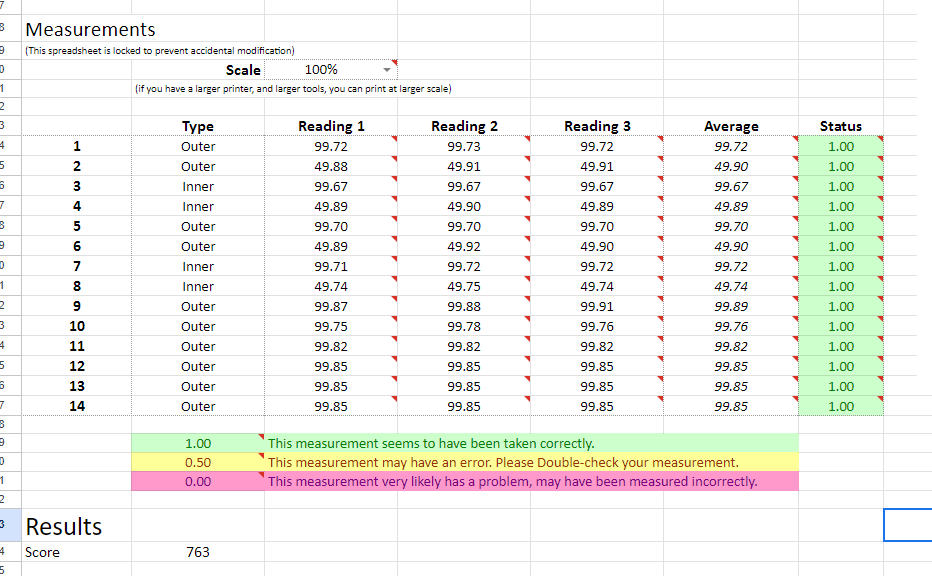

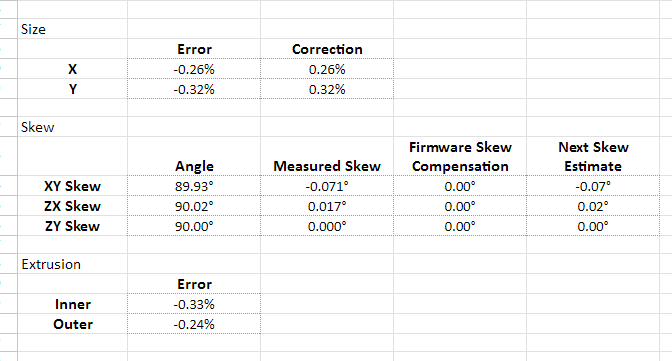

Second round with what I think are minor(?) improvements:

I wonder if I dealt with xy skew and tried again with another print and another xz yz skew, if I’ll get better results.

EDIT: actually glancing at the numbers maybe I just need to scale ever so slightly

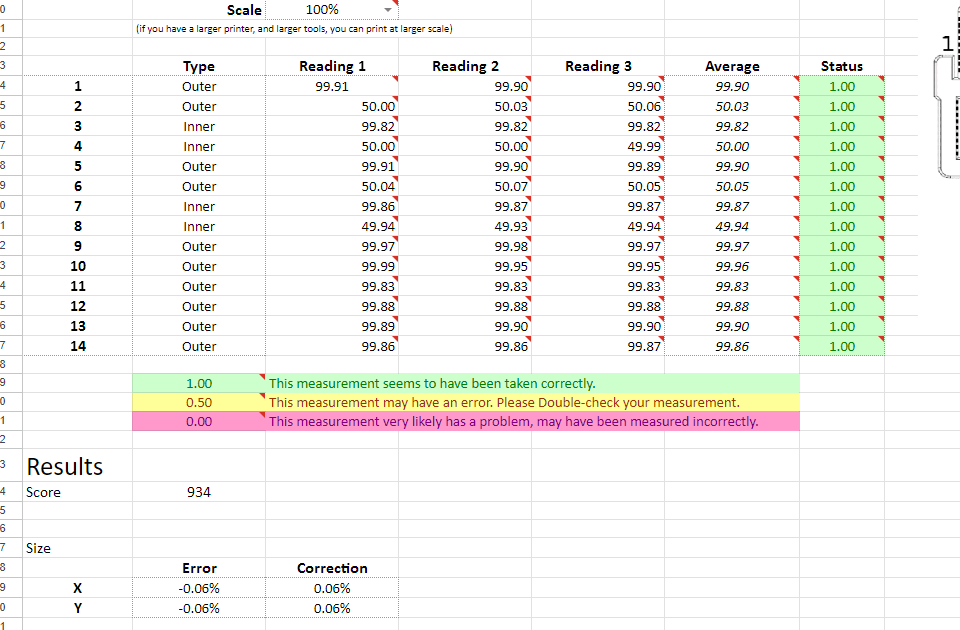

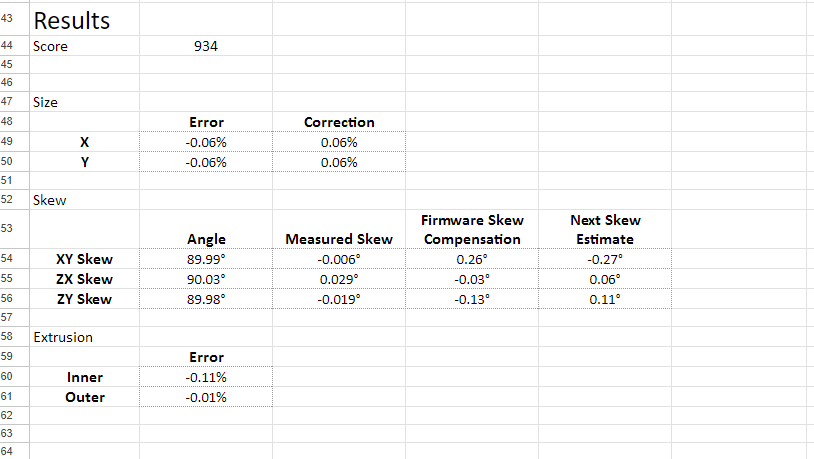

Third iteration, while less accurate it’s more consistent and resulted in a better score:

However, Ryan mentioned being less than .07 was good. If I’m looking at the correct set of numbers then I’ve gotten worse in that category.

I’m printing iteration number 3 while at work to see if it’s consistent with iteration number 2 and then I’ll probably just roll with it. At this point I’m just gaslighting myself.

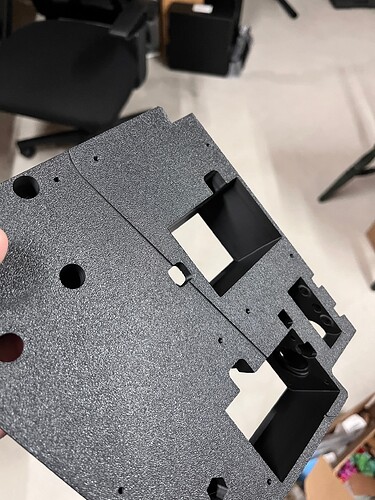

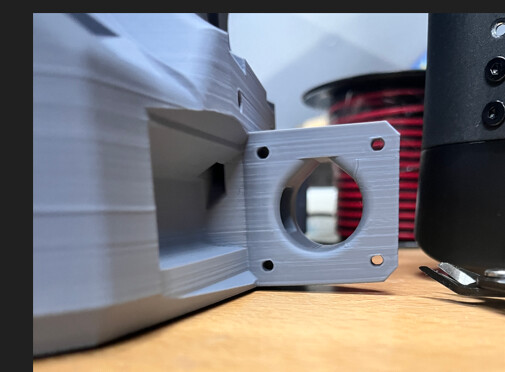

Slow going, but I’m a little concerned about the core, specifically the motor mount. It looks like it “bent” a little. That side was face down on the bed therefore it should be perfectly in line with the back portion. It was fine during printing and at completion, I’m guessing it happened during cool down. I question whether or not I should print another. I think it will be ok. This week’s goal is to start putting these parts together. I should know more later in the week.

You can see the gap where the “shrinkage” (not sure what to call it) occurred:

It really should not matter whether the motor is a little turned. It might be a sympton for an underlying problem, so keep that in mind should something be off with the core later. ![]()

So I think the industry term for that is “lift.” It can cause a compression in which one or two of the four holes is not in the right position, so it will really just come down to whether or not you can actually get the stepper motor bolted to it.

Guess, I’ll find out. I’ve set aside Thanksgiving weekend to start putting things together. Going Sunday morning to pick up the MDF to throw on the floor for the temporary table. Ordering the M5 dial today.