MESA THCAD-2 SCALE AND OFFSET:

Kudos again to Kyle, @kd2018 for his custom calculator as linked in his post here:

…which, as of today is still available here:

https://jscalc.io/calc/NTr5QDX6WgMThBVb

Since the THCAD-2 can (essentially) emulate a THCAD-10, I used the calculator with “10” selected.

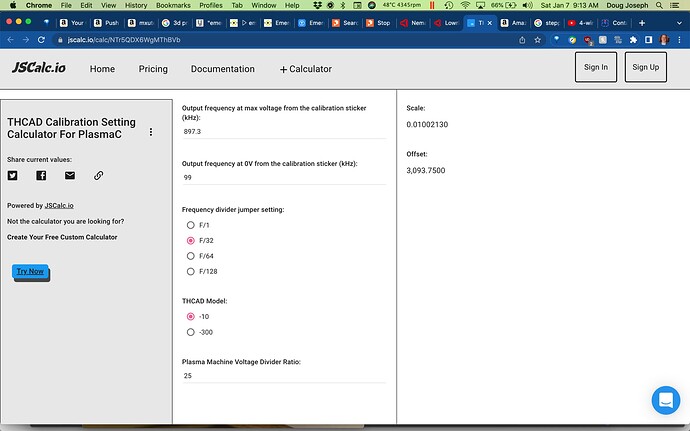

Here are the values, and a screen shot, for how I calculated the scale and offset for my THCAD-2:

Scale: 0.01002130

Offset: 3,093.7500

Based on:

Output frequency at max voltage from the calibration sticker (kHz): 897.3

Output frequency at 0V from the calibration sticker (kHz): 99.0

Frequency divider jumper setting:

F/1

F/32 <- selected

F/64

F/128

THCAD Model:

-10 <- selected

-300

Plasma Machine Voltage Divider Ratio: 25

-> "25" : For my 1:1 plasma machine with an HV resister (2.4M) inserted

externally on the negative lead, all based on guidance from

MESA's Peter C. Wallace ( @PCW ) on the LinuxCNC forum.