I guess the only easy one to specify is the YZ plate is 5mm from the surface if that helps.

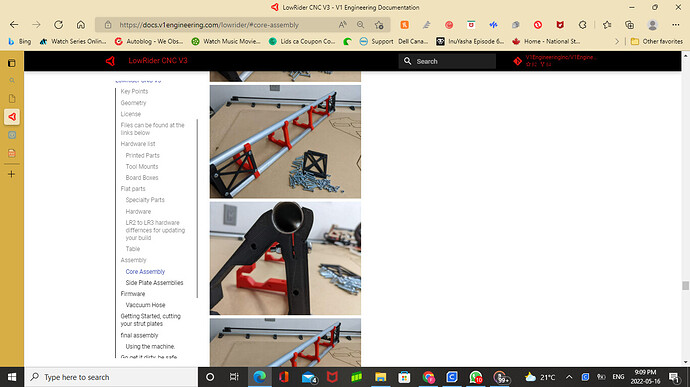

Added some 6061 plate option to the shop. LowRider 3 Metal XZ Plates – V1 Engineering Inc Steel ones are on the way.

Added the XZ dxf to printables and just about to add them to the docs with dimension details.

What if you just repositioned one of the Z endstops so it is level after homing? Would that not solve it?

The lower side? It would but it looks to eat up about 30% of travel, making it 30% taller probably makes it significantly less rigid. I strongly urge anyone that is wanting to make this thing any taller to also add a second set of bearing blocks to every rail, that means also modding the XZ plates. 80mm is good. much more and it absolutely needs more support.

In the other thread we discussed the bearing specs, this started with 2 blocks on every rail. I capped it lower 80mm just so we could save all that extra money on more bearings.

Hey crew ! I have a custom O.D. to my conduit and i would like to make the LR3 soon but it doesn’t seem to fit but my build will always stretch.

What’s thee inner measurements for these parts that hold onto the conduit in the imagines ? In addition i have included the O.D metal bar size and also did a mockup of the "rail- block 25 " ;its a printed part from the LR3 Print which i made bigger @ the percentage of 105.6 % . Depending on how these pieces fit it will better help me moving forward also if anyone has made adjustments please let me know peace!!

I’d rather not eat up any Z… that’s why I’d like to modify the side plates to compensate for this difference

It’s possible but the actual table is exactly 4x8 and I mounted the rails protruding from the sides and exteding long enough to make it a true 4x8 cutting area. I’d lose full-sheet capability with the LR3 way and would have to take the rail and belt on and off each time I used it for non-cnc purposes rather than just parking the LR at the end like I do now.

Yes! That should definitely help, thanks!

That is really awesome!

I took that .scad file and started playing around with it.

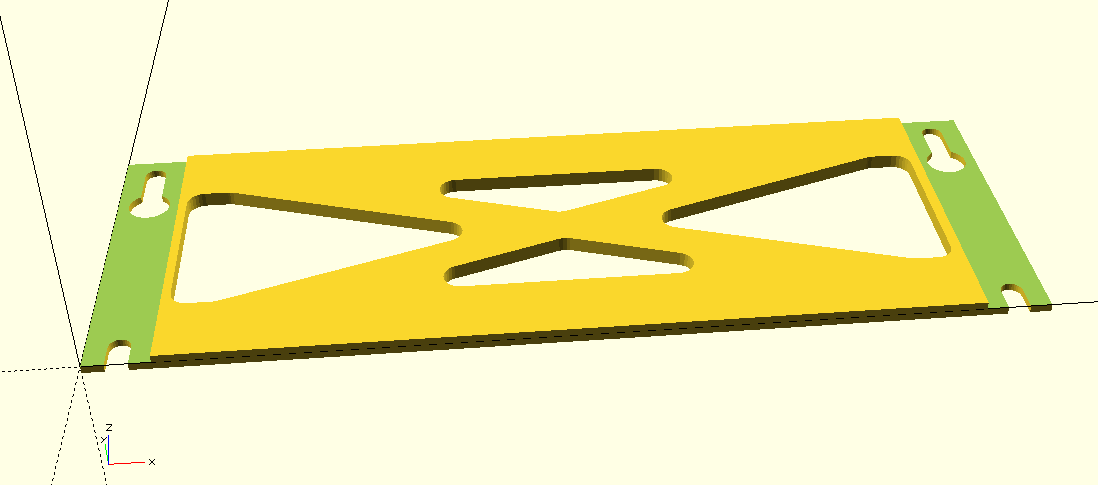

Would it help anyone to print temporary plates as modules? Like this:

(Flippable, just print as many as you need) for a 1400MM span, just print 7 identical parts, then when you can cut the final plates just swap them all out…

Not nearly as elegant as what @vicious1 designed for the temporary plate- but it could allow you to make a full span set without too much effort on a printer.

The code is ugly as can be because I’m still wrapping my head around what @jamiek did here… but:

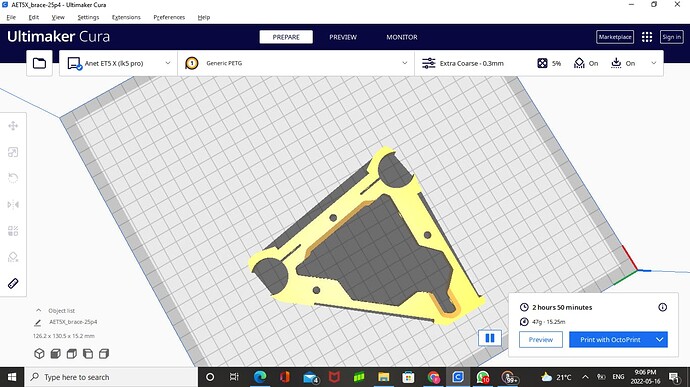

Doesn’t look like I can attach a .3mf or a .scad here in the forum. .scad is too ugly to share without me cleaning it up, but this would fit most 3D printers’ beds.

That will work, kinda, and we did discuss it in the beta. It will not be as useful as a complete plate though. The rails are not actually doing anything but helping with twist here. The plates do most of the work. You can use those instead of my temporary plates if you like.

You could print the module as a routing template and use the slots/keyholes to accurately locate the template as you work along the blank. In that way you could build the permanent part before you started, just using your router, and save the dismantle step.

I got some of these in the mail. I haven’t installed them yet, but they look and feel great.

Looks close enough to the 25.4 (1" OD) spec to me… For the Y rail, 1/2" conduit is cheap enough though.

Great work, just wondering if you are releasing printed part soon?

https://www.printables.com/model/204709-lowrider-3-cnc/files

Looks like it’s all there to me.

Sorry forget to mention I ment actual parts for sale not the files.

Would ABS be a suitable polymer for the printed parts, or should they be printed in PLA? I figure that PETG has too much flex to it, but ABS and PLA have similar rigidities.

I hope today.

No they are not very close. PLA is very rigid and prints with incredible accuracy. PETG flexes a lot more but also prints pretty well. ABS is slightly more rigid than petg but tends to not print nearly as well. 3D Printing Filament Guide

Not sure why people still use abs. The only thing it has going for it is vapor smoothing.

For a while I could find it at 8 bucks a roll. That was nice…

higher temperature handling compared to PLA and PETG before it starts deforming. (or cheaper than other harder to print materials like CF PC)

that is likely the main reason why it was not replaced yet

ABS is also useful (to me) for thing that I need to glue together, since I can do that with acetone, and vapour smoothing is nice.

I used to use ABS a lot, but once I got a printer dialled in for PETg, I pretty much switched wholesale.

PLA is still good for many things, but when I switched to ABS it was because I was getting a lot of brittle prints from PLA, and the strength of ABS was a big enough bonus to deal with the warping and dimensional shrinkage. PLA seems to be better now than it was then.