Very nice! I will be ordering some printed parts whenever that is not out of stock.

Steel PLates are in.

AL, 400g for the set.

Steel, 1100g for the set.

I doubt it will make much difference but I will put it out there like this. If you are prioritizing, Z moves get the AL, XY moves get the Steel.

What about the option for XY & Z? Titanium?

Only available to diamond V1 Crew members.

My question is how much of a difference do the metal plates make over plywood or mdf for the XZ?

I made a note somewhere. For the XZ the printed part is probabaly a bit better than MDF, the metals one are the only way to get any better than that printed version.

As for any noticeable difference, never measured. Might not be needed actually, but it looks great and makes for an extremely square and true build free of any printing defects.

That’s where my LowRider is going to go some day. I will create a table that can be folded in the middle, including wheels so it can be moved off the kitchen for parties in the garden and then folded down twice. Don’t have the exact plan yet, but the first ideas. Only problem so far is the tap. Maybe I can build one that I can screw off without water getting everywhere.

@vicious1

I wonder why you decided to put the one rail on top of the table, wouldn’t it be saving space by rotating it 90 degrees, and mount it from the side? A little notch could help to align the brackets.

In the end it would take up the same floor space, this way the belts stay on the outside. No extra standoff are needed to keep the table from hitting the wall when you are moving around in a small shop.

Wheels, Printables

Thanks but it seems like the files are for the bearing wheel. Here is the link I am looking at

https://www.printables.com/model/211714-lr3-60mm-wheel-brackets/files

Sorry that was sloppy of me. I fixed it.

Ryan, what are your recommendations re: bearing vs wheel?

I haven’t seen any mention (or haven’t noticed any at least)- the wheels I have (supplied by you) appear to be a fatter, flatter profile than what the two-colour versions appear to be, so it might be moot anyway.

cheers

Since wheels have diameter variations, I do prefer the Bearings. We all beta tested with wheels, the bearings were a last minute change and I do prefer them.

It also prevents the wheel from having any authority over direction. Bearings are just support, wheels have enough traction they can steer. So they require more attention to parallel YZ plates.

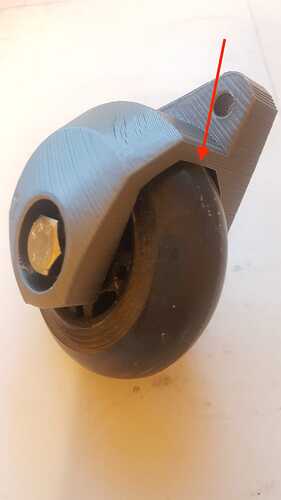

Ryan - I think the diameter got me. The wheel is a bit too snug

Will I be pushing my luck if I request for an additional 1 mm gap in diameter or may be a CAD file I can modify myself

Hey Ryan. Or beta team. Given the capability to cut 48" … built to the suggested dimensions, what is the actual cut width… 49 or 50 inches" just curious as to the over cut

Not much, 1/4-3/4 depending on the endstop location both axis. If you want overcut add more. I don’t think many people cut outside the sheet all that often. Most stay inside the sheet so exact is usually enough.

Is that from sagging on your print? I am pretty sure it fits up to a 64mm wheel. Changing that part has lots off effects. You can see there is not much space before you get to the YZ plate. Larger diameter wheels will also mean the YZ plates will be sitting pretty crooked relative to each other.

If those are my wheels, they really should fit, I am pretty sure we all tried them with a few of the wheels I sold over the years. Maybe a Z height calibration on your printer?

I doubt that because the wheel is snug at both ends. If it were just the Z that was off, then the side of bracket touching the print bed should have been unaffected (unless of course the calibration is off in X and Y directions as well). I tried scraping off the inside edges of the bracket but looks like the wheel is in contact all throughout.

It is a 64 mm wheel, so not sure whats going on here.

I was just wondering if we can accomodate the extra 1 mm by pushing the inside walls a bit, but if it is too much work or if it will cause other problems, then skip it. I will try to find a workaround before giving up on the wheel and moving to the bearing.

You already have the bearings and the files are available  and come fully recommended

and come fully recommended

Yeah I will change the docs to max of 62 wheels. I do believe the bearings are the better solution. I can look at edits of see if the CAD is good enough to go out but I really need to finish releasing it first. The wheels I sell are 58.5 to 60 so 63.5 is a bit larger than I planned for and made the YZ plate to fit.