@jamiek thank you for creating and sharing a set of strut plates together with a script that folks can customize.

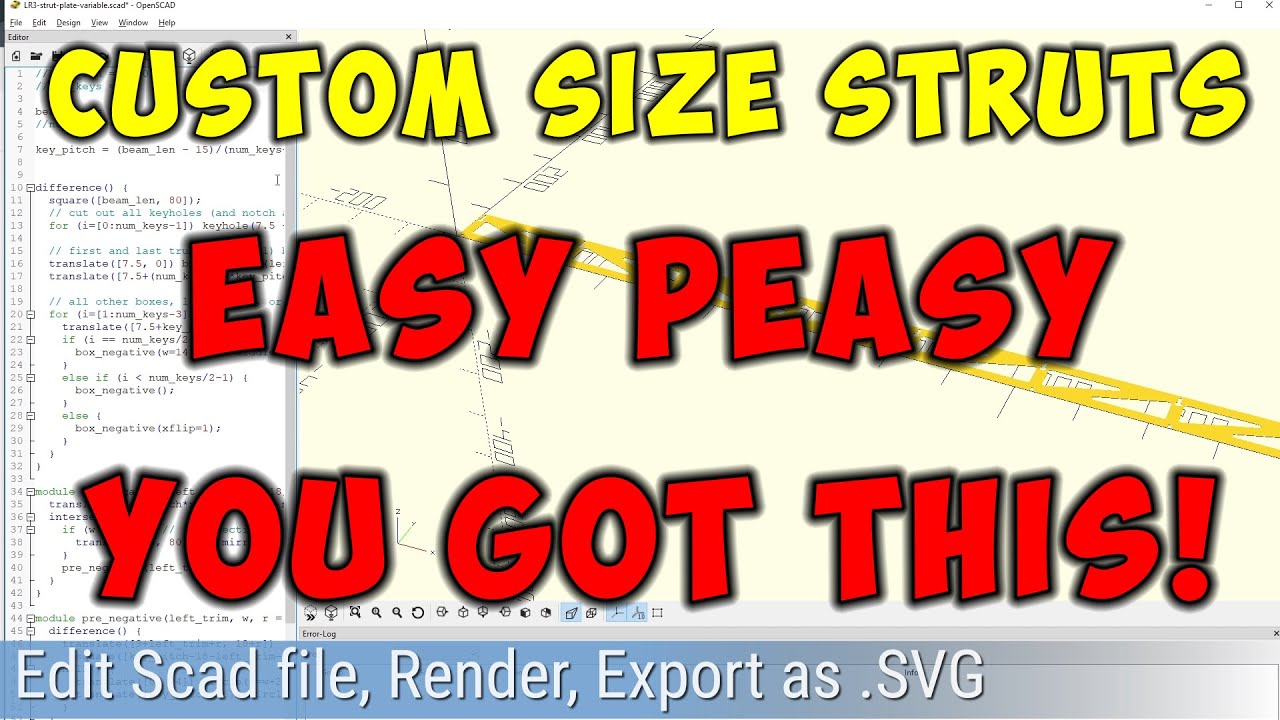

I foolishly spent some time making a video that may help anyone hesitant to try out OpenScad.

Then, sigh… I spent much less time making the video pointless for people that can live with Struts rounded to the nearest 10mm…

I just uploaded Strut Plates .SVG files sized from 480mm - 1700mm, in 10mm increments, to github. Please let me know if they’re wrong.

Edit number in the URL to the nearest 10mm size you need. So, now folks only need to generate a Custom sized Strut if they need millimeter precision.

Ideally, the LR3 Calculator would provide a link to one of these pre-generated static .SVG files. There’s few enough files, that are relatively small (123 files, total of 2.5mb), that the static files could be webhosted. I don’t think on-demand .SVG generation via Cloud App makes $ense. @jamiek, thoughts?