OK, I revised the TFT Holder and Reset Button, based on all your feedback, and additional realizations from your helpful photos.

I had the back of the PCB unintentionally mirrored in my model, which explains why I had the USB input port on the wrong side, and was mistakenly thinking the tall black sockets were on the opposite side. In addition to realizing that, which I addressed, I also did my best to take all your other feedback into consideration.

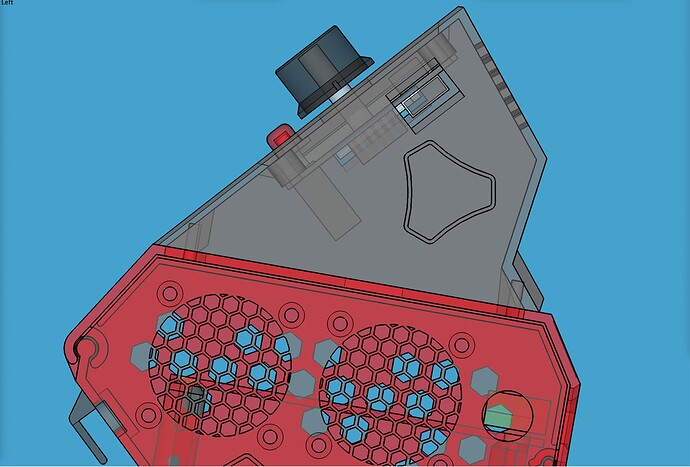

To get those tall black sockets moved further into the holder (and the connectors that get plugged into them positioned into the holder), I extended the back of the holder and moved everything further into the recess. That gained something like 13mm of additional “headroom.” I also gained another 1.5mm of headroom by using a factor of 1.5mm in shortening both the screw hole standoffs, and the rectangular ridge standoff for the screen. I also deepened the recess of the reset button by both the 1.8mm you mentioned (I rounded up to 2mm) plus the aforementioned 1.5mm, so 3.5mm total. I also corrected the placement of the large hole for the knob axle protrusion.

I’m reasonably hopeful this revision will be the golden goose for you, although I’m not 100% it will all fit right now. If you are willing to to print again, I think you will be pleased and do request additional feedback on it.

The download page on Printables has been updated:

https://www.printables.com/model/235351-lowrider-3-cnc-control-box-case-for-btt-skr-pro-12