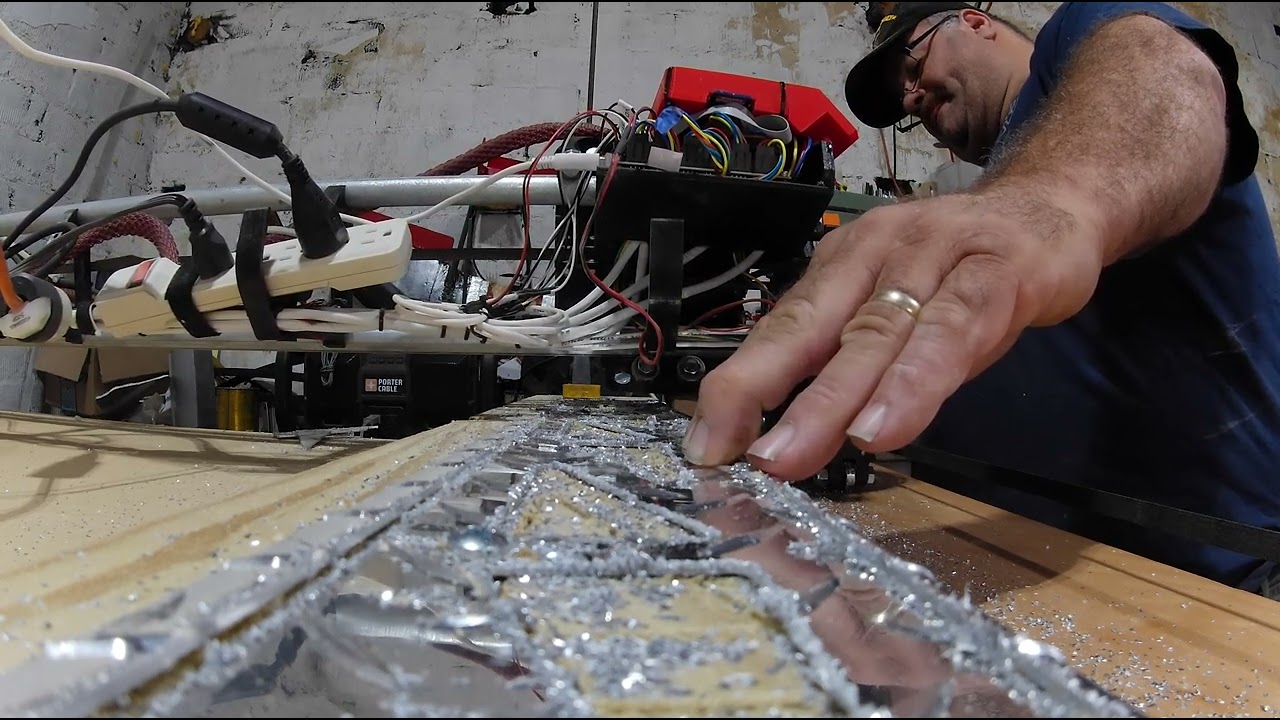

Making Diamond plate struts am I running to fast using dewalt at full speed or maybe wrong bit edges seem very rough although it dos flake off easy with sand paper

It that aluminum or steel?

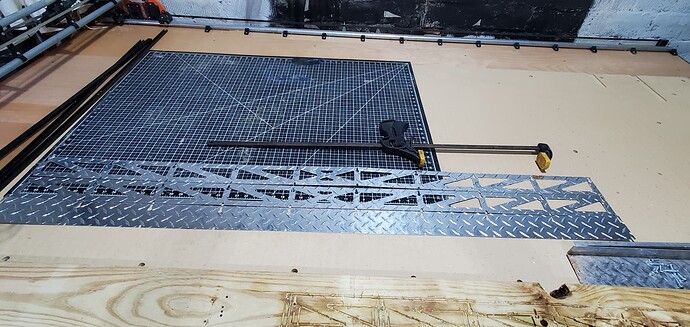

This is probably the first metal cutting with the temporary plates only. Very exciting?

I’m not that experienced with metal. But my first guess is that the chips are getting fused to the work because they are getting recut.

Two things I would try are: 1) Add a finishing pass in CAM. That will just bring the but around again to clean off the chips. 2) Add an air assist. You can try it manually for an inch and if it works to keep the chips away, then try to find a way to add it to the machine. Jist some direct air on the bit yo push chips away from the cutter as they come off.

But metal is a bit of a mystery to me. Maybe someone else will tell you if you need to go slower, faster, deeper, shallower.

Guessing Aluminum from topic title, if using strong steppers like the Nema17 76oz one’s V1E sells in the LR3 kit, consider leaving the front Strut solid, save on cut and cleanup time without adding much weight. Personally like look of a solid front grill. a solid diamond panel for front grill would look slick. For easier life, recommend assembling struts in sequence… bottom, front, then rear.

Used the following settings with a 1 flute bit came out pretty Clean… I assume people are doing all 3 struts ?.. Just Realized Going to be 2 gantry Braces short at 65" it calls for 10 and I only have 8 Guess I am going to have to fix 1 off my 3D printers pretty quick

P.S. I like the Idea of a solid Plate on the front Behind X Belt

Love the Idea of Solid front Plate will do that

Nice! Look forward to seeing final assembly.

Engraved logo, name, measurement markers and no cut zones on my front Strut, details in my build topic. Not sure if engraving patterns is what you’d want for yours though, that might ruin the purity of your diamonds ![]()

I am kind of at a stand still until I either get 1 of my 3D printers fixed or order 2 more Gantry Braces from Ryan I ordered all my 3D printed parts. I Wore out my 3d printers making Face shields and Ear savers during Covid-19 for all my fellow EMT,s and Hospital works round the clock my Gantry is 65" looks like it takes 10 Braces only came with 8

That’s awesome Marvin. Respect. Best use of a 3D printer.

Black PLA, what’s your gantry conduit 3/4" EMT? At 1760…Rd, VA?

Yes 3/4 EMT yes 1760 Fairview Rd. N Chatham VA. 24531 … Yes I am Volunteer Fire Fighter & EMT I will be happy to paypal you the money for the Prints and shipping…

Thank you for helping others! Braces on their way

That is so nuts!

How did you end up getting clean edges, faster feedrates or slower RPM?

Lowerd to 300mm/min slowed the router way down to about 2 that stopped the Aluminum from gumming up the bit and gave me nice clean cuts also used a single flute bit

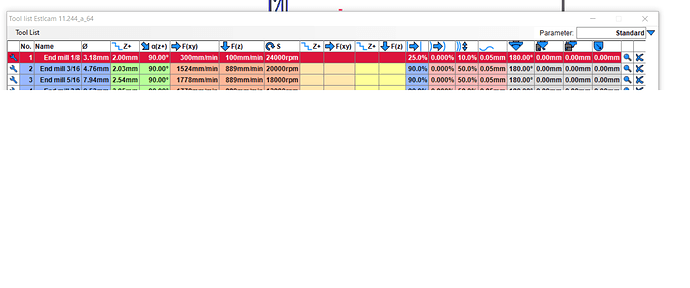

@marvinlange, am I reading EstlCam config in your earlier post correctly Lowrider-3 aluminum strut plate - #4 by marvinlange ? Did you manage 2mm depth of cut passes at 300mm/min feed rate with your carbide single flute bit?

Yes sir… but keep in mind it was a very soft aluminum… made to be trim on sheds was only 2mm thick I found if I moved to slow the bit would heat the aluminum and stick to bit clocking flute… I ruined server pieces before settling on that speed also had to turn dewalt router down about 2 to help keep cool. Tried using WD 40 that was available but did not seam to help other making chips stick to everything

Ethanol is good for aluminum milling. Makes cuts really clean by cooling and lubricating. And it evaporates easily so it doesn’t leave a mess. Of course it smells quite a bit, but whether that is a pro or a con depends on the operator.

Cool had no Idea looks like its time to fire up the still  and buy a bigger fire Extinguisher.

and buy a bigger fire Extinguisher.

Almost thier just wish I would have rembered to put Z axis. On the gantry before I put the ends on. Waiting on new enclosure big enough for my Rambo board and PI 4 also going to use aviation abulk head plugs

I tried this and you are so right. I love it. No mess and aluminum is actually pretty easy to mill now. Thank you!