Today could be described as “interesting” I suppose.

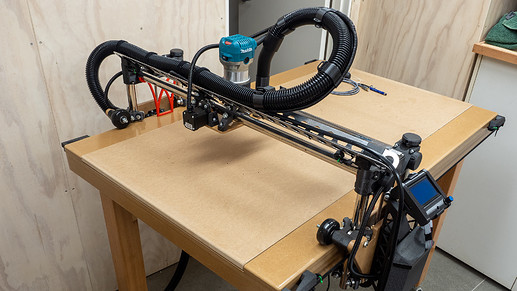

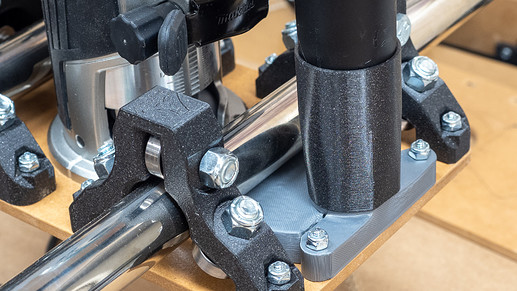

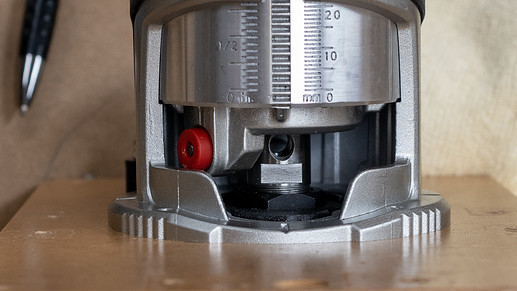

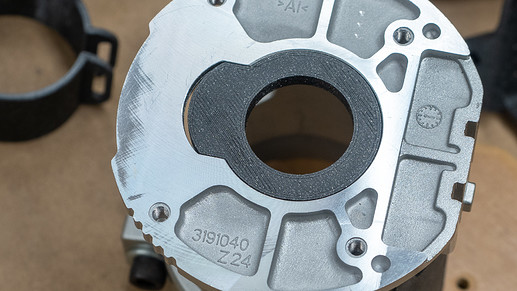

I have many questions to ask regarding the “700 (was 611) plate” and will save most of those for the next round - actually having the thing working may well answer them. For now, I have decided to use my something a bit less than 1 1/2" shopvac hose, mostly because it’s new and shiny looking, but also because with a new adapter it fits exactly onto @vicious1 Ryan’s stock parts.

Not much more than a year ago, before I had a 3D printer, at a time where I had never drawn anything on a computer, I would have simply grabbed an PET old soft-drink (soda) or water bottle and made an adapter by heat shrinking it. Sometime this afternoon, brain completely disengaged by way too much Mexican F1 Grand Prix at three o’clock in the morning, I thought I’d just do that as a temporary measure.

NOTE - PLA does indeed assume vastly different shapes if you heat it to the temperature that is necessary to make PET shrink. Thankfully with a bit of judicious patting and tooling, damage was minimal!

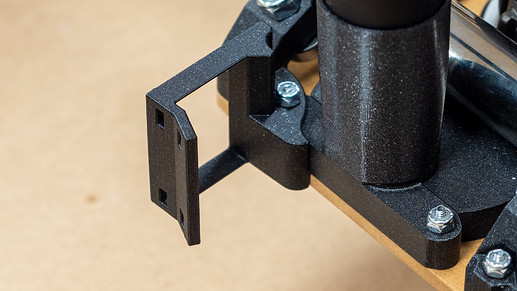

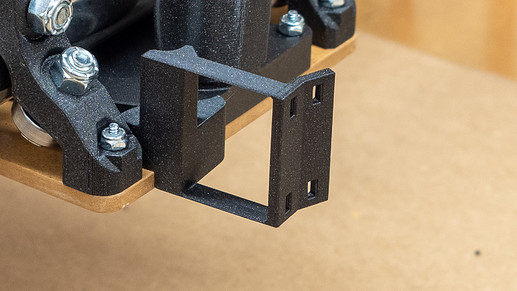

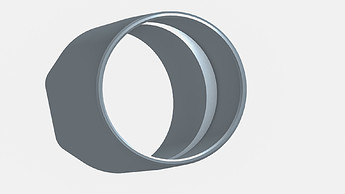

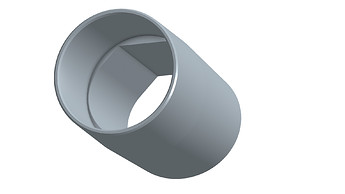

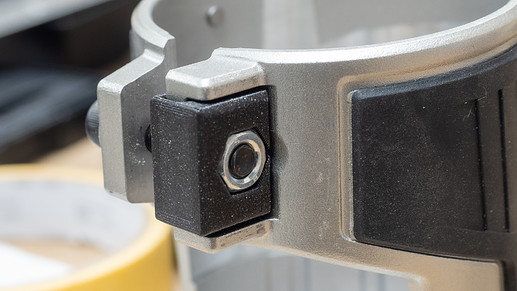

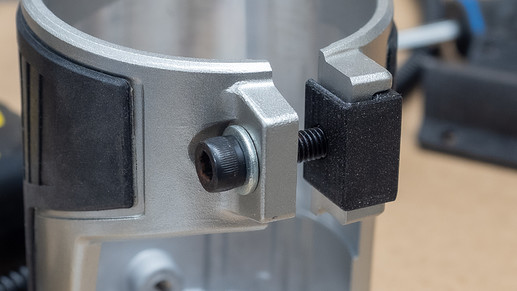

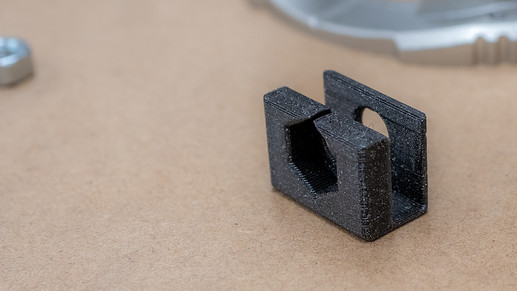

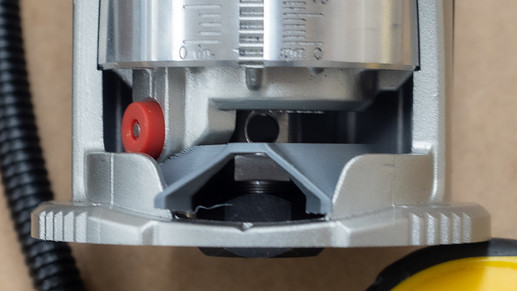

I understand completely why the vac inlet is oval with a flat spot on it, but sadly my vac attachment is round and quite rigid, and in less than the time it would have taken to search Thingiverse, I had a quite tidy connection drawn and printed. It’s vaguely complicated but it will do for now.

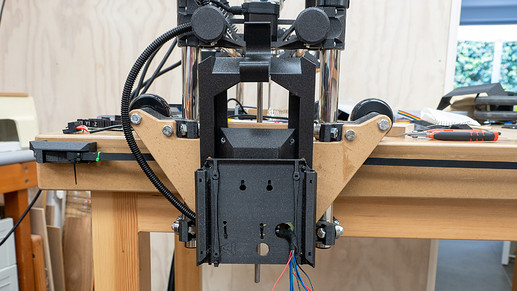

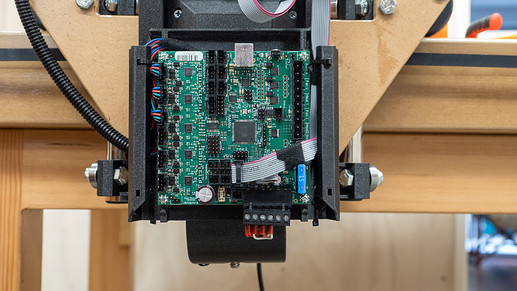

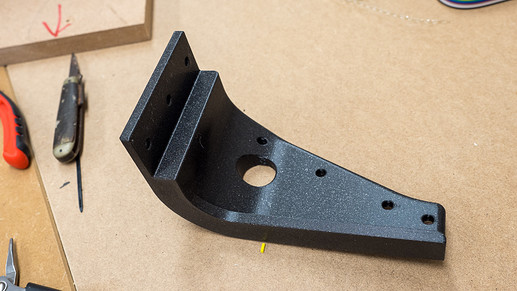

With that sorted it was time to mount the final version of the board and screen brackets and while I had allowed half a millimetre clearance between the back of the screen and my fancy pipe plugs, I chickened out and made a couple of spacers to prevent any future issues.

With only the board end of the wiring loom to go (twelve more pins by my count) I removed and adjusted the grub screws on the couplers and pulleys and gave them a generous splash of locktite before fitting the cover over the stepper.

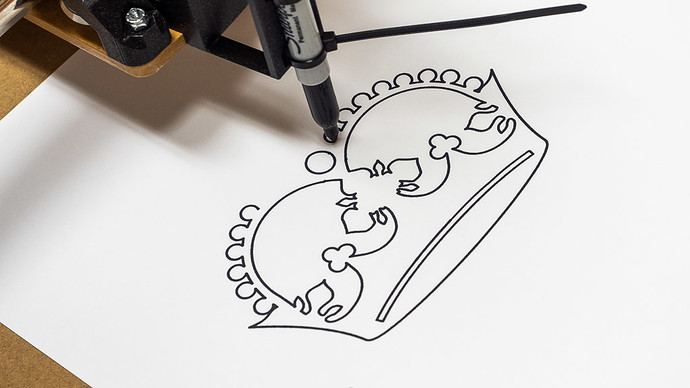

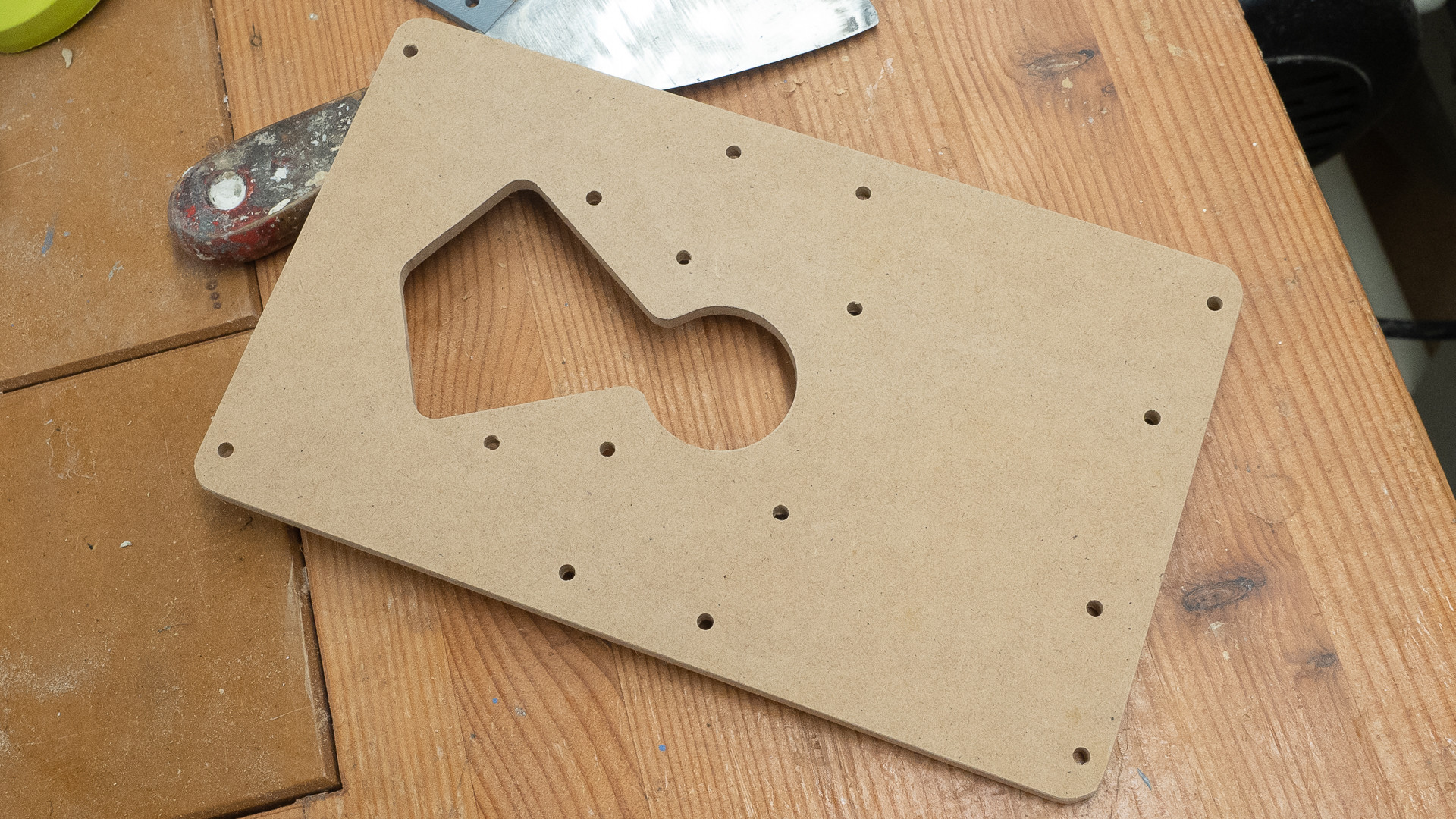

About now I’m wondering just how temporary those temporary MDF flat bits are, but that’s where I’m up to. It can’t be long now. Can it?

I’ve run the vac to the “off” side just to keep things tidier on the side I have to be working. The clips seem to secure it well enough that I might route it back the other way one day.

I’ve run the vac to the “off” side just to keep things tidier on the side I have to be working. The clips seem to secure it well enough that I might route it back the other way one day.