There are a few things that I did to my plate armed with a little experience from other dust collection setups in my shed:

-

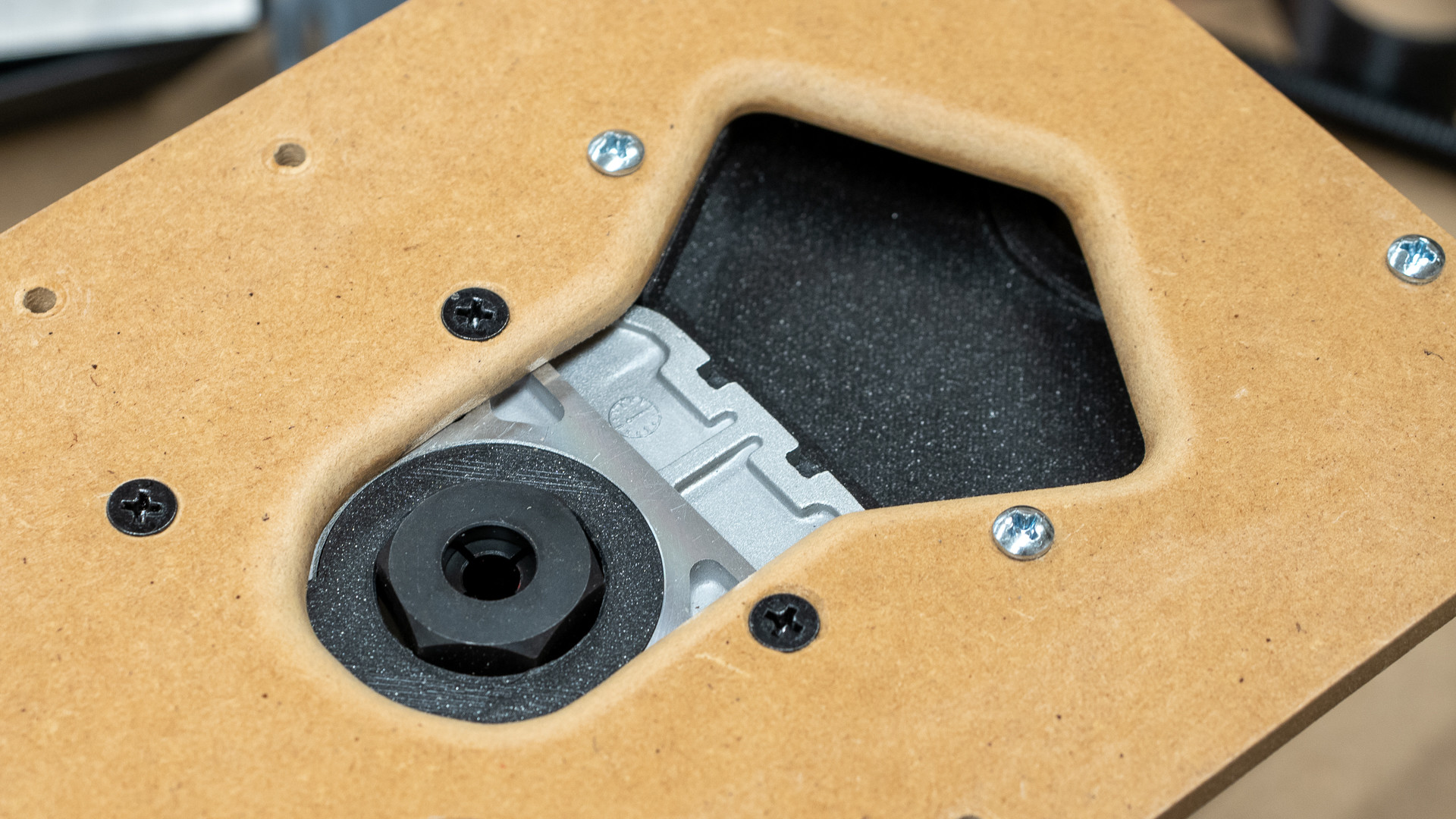

- the Makita has a different setup to the deWalt so the “keyhole” is not necessary IMHO - just eliminate it and make a straight run to the vacuum pickup.

-

I was concerned that by removing the material in question immediately below the vacuum port - (the vacuum is a relatively high velocity inlet) more air could be drawn from a 360° range rather than more-or-less from the direction of the cut. (I had intended to do some actual research on this using tell- tales to view the air flow but have abandoned that due to the impending LR3 base looking a lot better from that perspective!)

The area of air intake between the base and the port is greater than the area of the vac inlet itself, so apart from the right angled bend - no loss of velocity should occur - and I think the right angled bend is advantageous.

-

Rounding off the edges of the base will assist air flow enormously - I used a 6mm round over bit in the router.

-

Because of the differences between the Makita and DeWalt I argued the point of @frederik 's replacement for @vicious1 Ryan’s “vacduct” part which was designed for the DeWalt. I understand that pretty much everyone who uses the Makita uses that part happily, but my logic is set out in the link below.

I have also designed a simple insert - but again warn that it’s not been compared to anything so may not work as well as the original.

NOTE - just because I have nice photographs and a perhaps logical argument does not mean I am right - I haven’t done any comparison tests to prove this logic!

I have drawings of this baseplate in .dwg and .dxf format HERE

Pictures of that part of my build are at the following link.