If you’re the kind of person for whom building is the means to an end rather than a journey itself, it might pay to avert your gaze for a bit.

I thought I’d drill a few holes in the back of the Rambo case to hide a bit of wiring, and in the process remembered how I quite like using the step drill. The only thing lying around that looked as though it could do with a few dozen big holes drilled in it, was the aluminium angle that will one day carry the vac pipe.

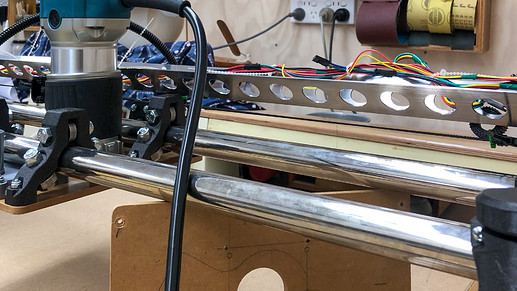

So I spent a pleasant morning making a jig and drilling to my heart’s content, followed by a bit of a rub with Mother’s Mag Wheel polish for good measure. The printer is printing the final case mounts, we’re still going away for a few days, so it what nicer way to take my mind off firing the thing up?