Is that the first error? Only the first error matters.

But open failed sounds like you’re out of disk space or something.

Is that the first error? Only the first error matters.

But open failed sounds like you’re out of disk space or something.

Hi. Yes, the first error. It seems related to the upload function. The image compiles fine locally. Then save to SD card and insert into the motherboard and boot.

All working now. I will sort out the upload error at a more convenient time.

However, the SKR TFT screen has everything backwards. Clockwise is up, and anti-clockwise is down. What have I done wrong?

Duncan

The tft is in marlin mode?

I think there is a fix for that, but it isn’t in 505. Something in the lcd section of the marlin config called reverse encoder, I think.

Found it. Thanks

Well, so far, so good. Z-axis steppers behaving themselves nicely. Touch wood. Any idea how I can stop Repetier from rebooting the motherboard whenever it connects?

Duncan

Nope. Let me know if you figure that out.

Ungh. They are so inflexible. I wonder if cncjs does that.

They also don’t recognize G92 because they think they know better.

If you want extra torque, https://www.filastruder.com/collections/electronics/products/super-whopper-motor

Hi Barry,

Thank you for the link. I will keep it in my CNC folder in case I need it in future. HOWEVER, since rewiring my LR2 from scratch using SKR Pro 1.2 and Ryan’s dual image - the LR2 is behaving itself beautifully. No Z-axis drops at all.

In fact, I have only two quibbles:

(1) Because of the sled on which the router sits, I have to extend the bit by 10mm just to clear the sled. So when cutting 9mm ply with a 3mm bit, I have to have 10mm + 9mm +1mm = 20mm bit extension - which is over-spec for the bit. The sled is also in the way, and I can’t actually see what the bit is doing during a cut.

I have quite a lot of 3mm 6061T6 sheet in the workshop - I may try cutting a new sled out of this, and claw back 5mm or so.

(2) The LR2 really struggles rigidity-wise when I’m cutting 18mm ply. For that I’m using a 6mm 2 flute upcut bit, and going really slowly with shallow passes. This requires 10mm + 18mm + 1mm = 29mm bit extension, which is again way over spec for a 6mm bit. The cut lines are clearly not perfectly even.

Other than that - all good this side… SO HAPPY about the Z-Axis steppers behaving themselves.

Duncan

18mm plywood shouldn’t be a problem. Reference Barry’s photo. The collet should be capable of being on plane or slightly past the x-axis sled plane.

While it may or may not be recomended, I run my LowRider without the vacuum duct.

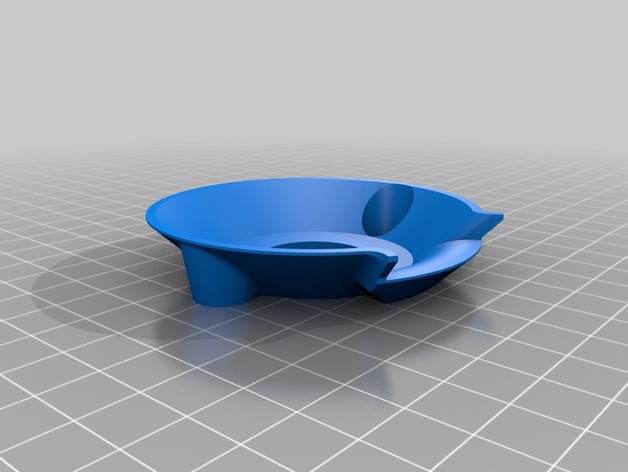

I had to squish my vacuum duct down by something like 25% in my slicer before I was happy with the router position.

Mmmm… Thank you. My router gets nowhere near the bottom of the plate. Unsure why, but it isn’t due to the vac plate. The router hits the bottom of its sleeve, and that’s it… But I’ll take another look.

Duncan

@rtfm - A photo of the router mounted on the plate would be helpful for those of us hoping to assist with this.

Hi Tony,

Sure thing - except that I’m in the middle of levelling my table (first spoil board completely wrecked by my beginner stuff-ups). Heh heh…

Duncan