Making some stuff real again.

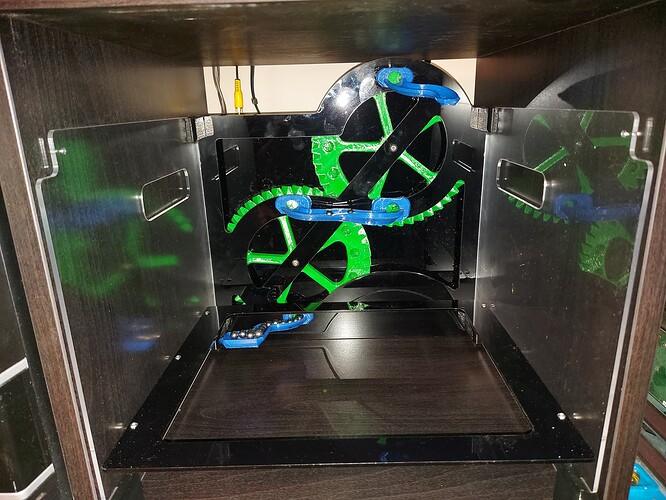

Okay, so I carved out the frames from 1/4" melamine/MDF, and an extra front frame from some 1/4" MDF left over from my Repeat build. I missed the corner by about a half inch or so, or else I could have used it.

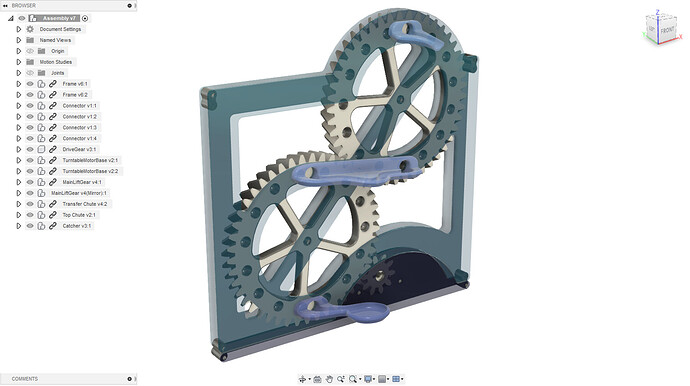

Anyway, as proof of concept for how the frames will stack, it works well enough. With the marble transfer chute printed mirror imaged, that will manage the uptake. I’ll need to design an intermediary chute for the downward path… uses the modules exit directly below the entrances… Hmmm…

I carved one main gear from plywood, stuff didn’t fit. Minor adjustment, 3D printed one… didn’t fit. This time I carved it from foam…

But of course…

Shoulda done that first. The foam is 13mm, so a bit thicker than the 12mm that I designed for, so I had to finish cutting it out with an exacto knife, but this side is all milled, so is a good representation of what the Gcode will do with the real material. Or if I 3D print one based off of the revised file.

The wheels are set up for some bearings I had lying around, sure hope I can get more. Well they are the ones that the POM wheels are based around. 10mm OD, 5mm ID, 4mm thick, so shouldn’t be a problem to get some somehow. I’ll need a spacer for the center, and washers for the ends to keep stuff from rubbing.

Also printed the little connector pieces for stacking and installing the power base. I suppose I could make an integrated unit that always has to be on the bottom. I’ve been working on this as if I mean to put them into production or something… odd that I’d design that way for something I’m making to amuse myself. Maybe I’ll put some at the local maker’s market, see if I can at least cover material costs…